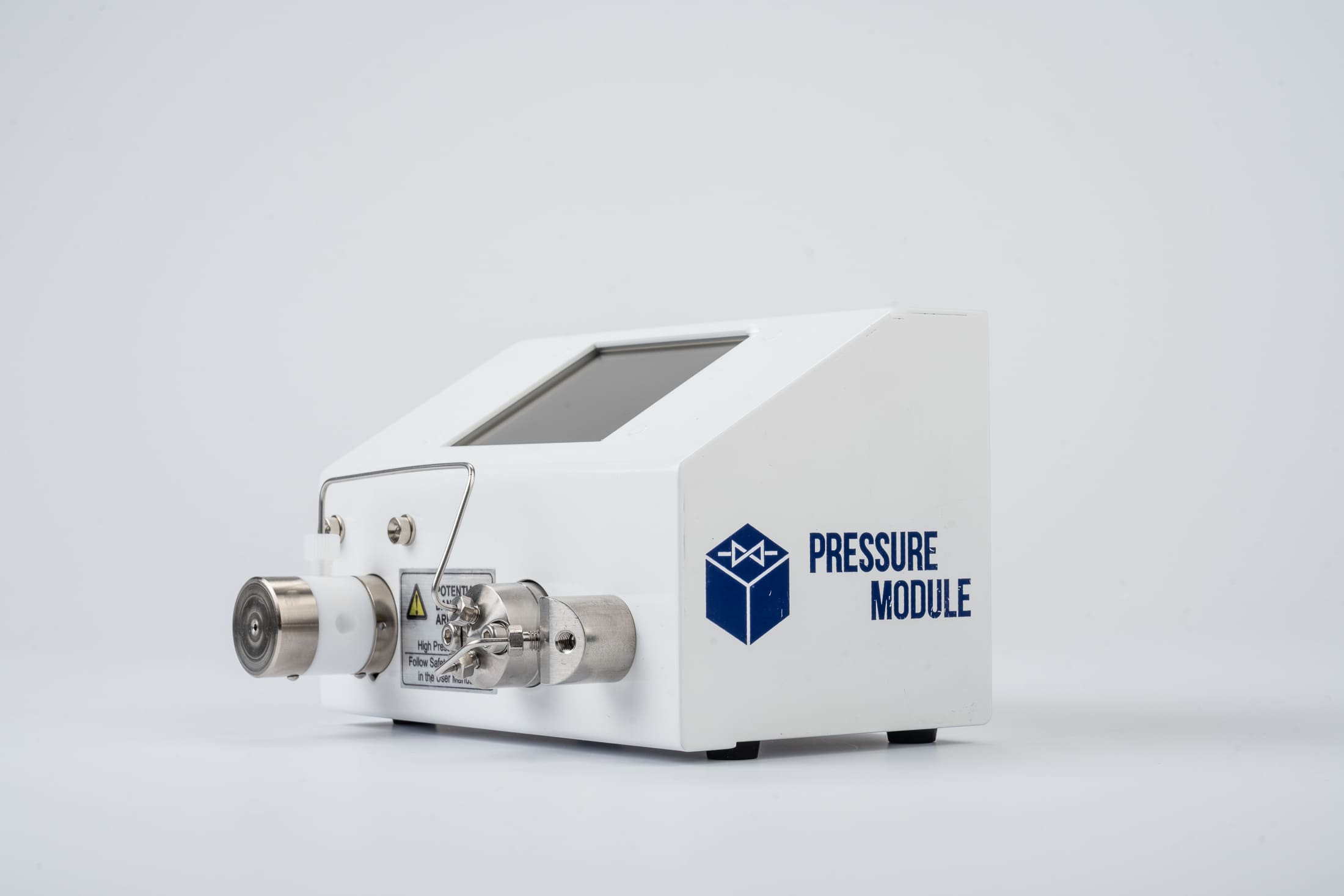

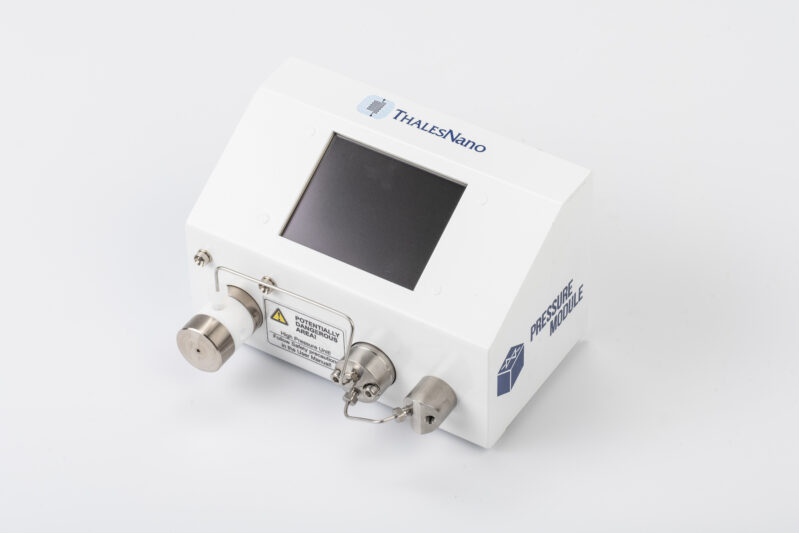

Pressure Module

Efficient and Reliable Back Pressure Control

Control and Monitor your System Pressure

The Pressure Module is an easy-to-use motorized back pressure regulator designed for liquids, gases, or gas-liquid mixtures. As part of a continuous flow reactor system, it allows for seamless and reliable control of the reactors' system pressure levels. It consists of a built-in pressure sensor, a pressure regulator valve, and a switch valve. The device is also equipped with a user-friendly touchscreen which can be used to control and monitor pressure levels within the system. Fully compatible with other ThalesNano instruments — including the Instrument Fleets and the Phoenix Flow Reactor — the Pressure Module provides comprehensive control over your laboratory processes.

How does the Pressure Module work?

Designed for handling liquids, gases, and gas-liquid mixtures in a modular system, the back pressure regulator allows for seamless integration with ThalesNano's other products like the Instrument Fleets and the Phoenix Flow Reactor. Reactions, such as carbonylations or oxidations, can be performed at high pressures, widening the chemistry ability of the connected reactors significantly.

- The touchscreen interface allows users to easily set system pressure up to 200 bar (2900 psi) and monitor pressure levels in real time.

- The built-in switch valve can be used to direct the fluid stream either into a product collector or to waste by adjusting the switch valve’s position through the touchscreen.

Specifications

| Technical data | |

|---|---|

| Pressure range | 2-200 bar (14.5-2900 psi) (with a flow rate of 1 mL/min IPA) |

| Pressure tolerance | +/-2 bar |

| Maximum Gas flow-rate | 1-1000 NmL/min |

| Maximum Liquid flow-rate range | 1-20 mL/min |

| Maximum liquid temperature | 100 °C (212 °F) |

| Inlet port | UNF-10-32 for 1/16″ |

| Selector valve outlet ports | 1/4-28 Flat-Bottom for 1/16″ |

Do you have more questions?

Reach out to us at any time and experience fast and efficient support tailored to your specific needs.