THS System Controller® and

THS ReAction® software

Control your ThalesNano system remotely

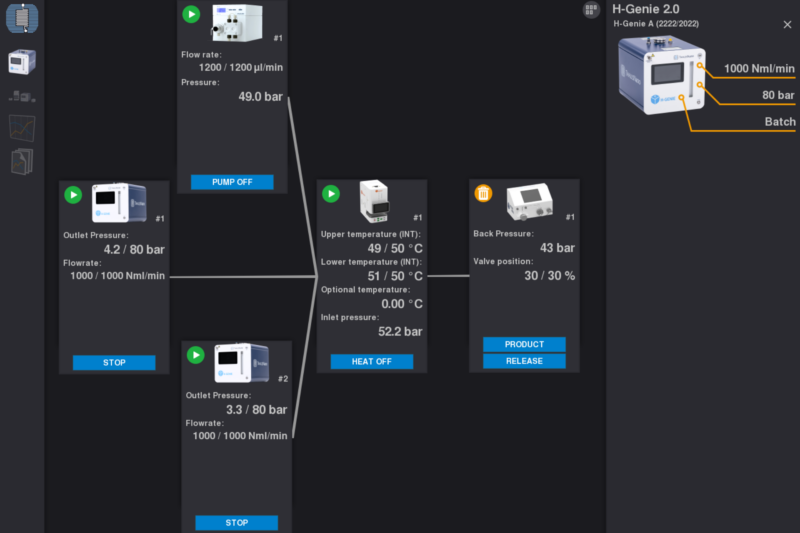

As part of the Phoenix – H-Genie® platform, the THS System Controller® and the THS ReAction® PC application are designed to efficiently control ThalesNano laboratory flow chemistry reactor modules using a computer with user-friendly software. While the THS System Controller® establishes seamless communication between the laboratory devices and the computer, the THS ReAction® software enables remote control of all modules in the system.

Software Functions

Software Demo

Remote Control of All Attached Modules via the Software

ThalesNano’s THS ReAction® software offers a seamless and user-friendly interface to remotely control all laboratory flow chemistry reactor modules. With this feature, researchers can conveniently and efficiently manage various reactor components from a computer, eliminating the need for manual adjustments and increasing experimental precision.

Option for Controlling Third-Party Modules

The software’s flexibility is designed to extend beyond ThalesNano’s own modules. On custom request, researchers can integrate and control third-party modules, enabling compatibility with a wider range of experimental setups. This open and adaptable approach allows users to harness the full potential of their existing laboratory equipment while benefiting from the enhanced capabilities of THS System Controller®.

Individual Control of All Reaction Parameters

One of the software’s key strengths is its ability to provide precise control over all essential reaction parameters. Researchers can tailor and adjust temperature, pressure, flow rates, and other critical variables on a module-by-module basis. This level of customization empowers scientists to optimize their experiments according to specific reaction requirements and achieve reproducible results.

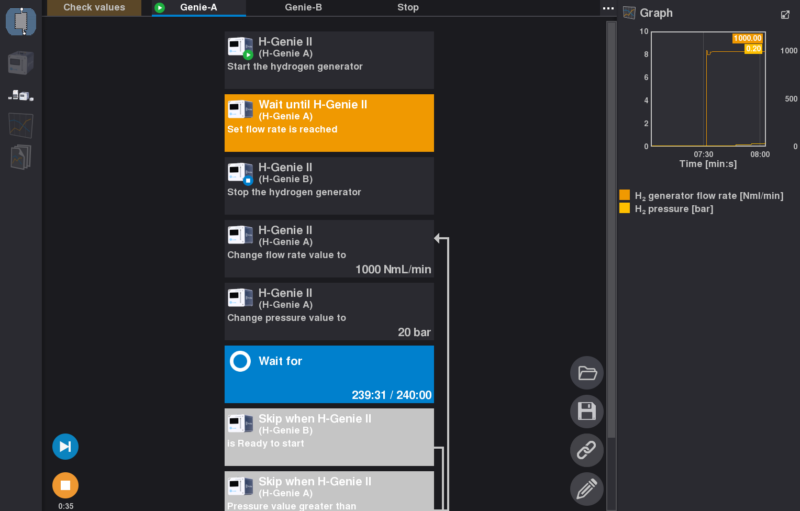

Automated Operation Mode for Enhanced System Control

THS ReAction® software incorporates an automated operation mode, which streamlines and optimizes the execution of experimental protocols. Researchers can program the software to follow predefined sequences, execute step-by-step instructions, and adjust parameters automatically at specified time points. This feature not only reduces the risk of human errors but also allows for unattended, long-duration experiments, freeing researchers to focus on other important tasks.

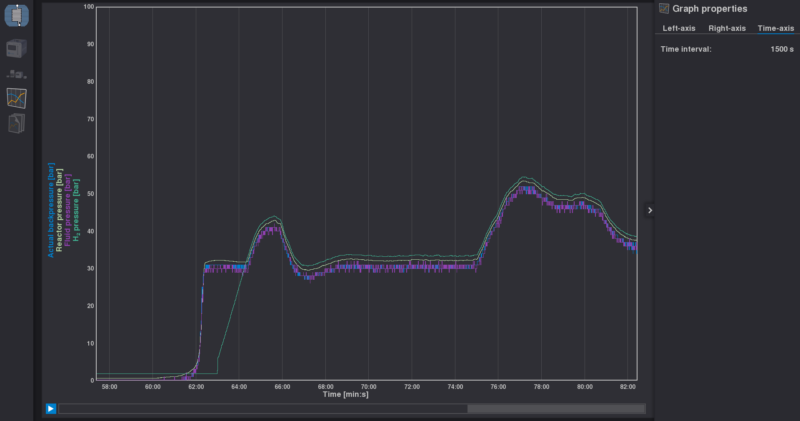

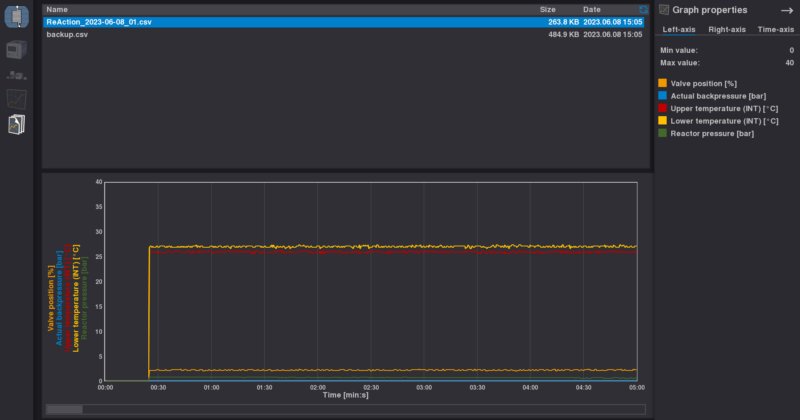

Real-Time Monitoring of Reaction Parameters

The software provides continuous, real-time monitoring of crucial reaction parameters during the experimental run. Researchers can track variables such as temperature, pressure, and flow rates on a dynamic graphical interface. This immediate feedback facilitates quick decision-making, enabling adjustments or interventions as needed during the course of the experiment.

With built-in safety features

- Maximum column temperature setting

- Temperature regulation for solvents based on applied pressure

- Automatic process control during reactions

- Emergency shutdown protocols for added safety

- Customizable temperature, pump flow rate, and back-pressure control

- In case one of the devices is disconnected (or any parameter exceeds the normal limit of the reaction), the reaction can be automatically stopped, and an emergency process can be initiated

Use the Software in a Modular System

Compatible ThalesNano Modules

Phoenix Flow Reactor >>

High-performance flow reactor with an extended parameter window (temperature up to 450°C, pressure up to 200 bar), enabling the synthesis of novel compounds.

H-Cube® Advance >>

New generation flow reactor, built for heterogeneous catalytic reactions. Produces hydrogen on-demand with flow rates up to 70NmL/min, at temperatures between 0-150°C and pressures up to 100 bar.

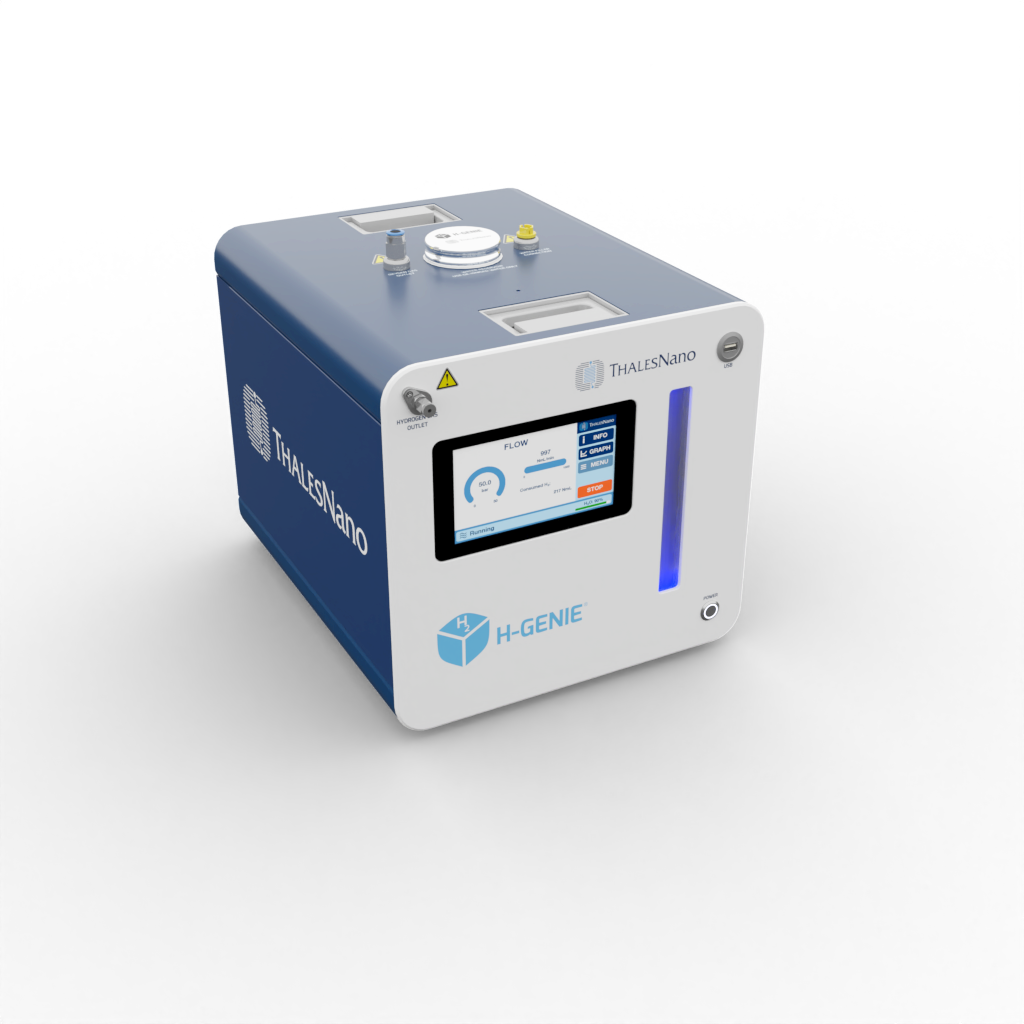

H-Genie® >>

On-demand, high pressure (up to 100 bar) hydrogen generator, producing 99.99% (4.0) pure hydrogen gas via water electrolysis, with flow rates up to 1NL/min.

H-Genie® Lite >>

On-demand, high pressure (up to 50 bar) hydrogen generator, producing 99.9% (3.0) pure hydrogen gas via water electrolysis.

Gas Module / Gas Module Plus >>

Designed for the precise dosing of 14 different gases at flow rates up to 1NL/min and up to 100 bar pressure.

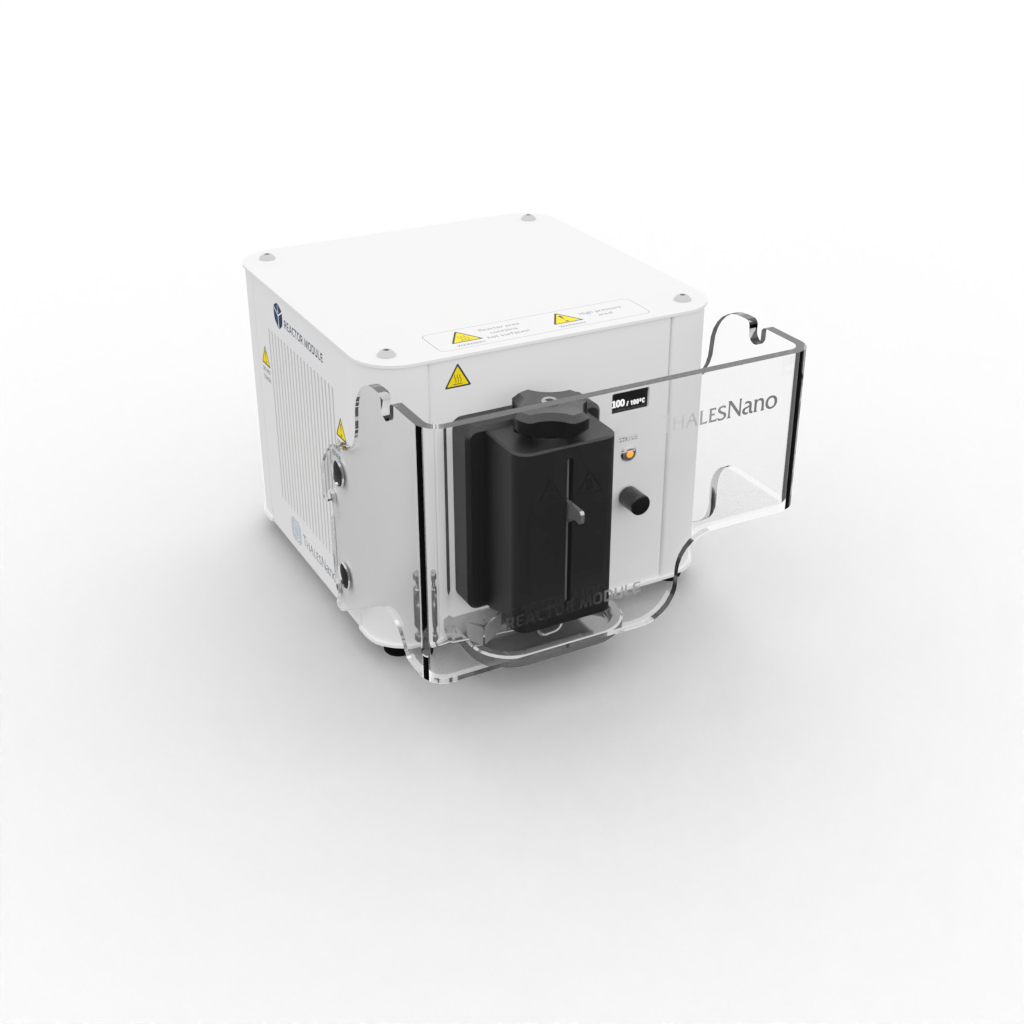

Reactor Module >>

High-temperature, high-pressure reactor unit for catalyst testing, catalyst screening, and multi-step reactions.

Pressure Module 2 >>

New generation motorized back pressure regulator with a built-in pressure sensor. System pressure can be set up to 200 bar and pressure levels can be seamlessly monitored.

Mixer Module >>

High-performance static mixer for gas-liquid mixtures. Operates up to 200 bar and supports a wide variety of gases and liquids.

ThalesNano Micro HPLC pump

3 mL/min or 10 mL/min capacity pumps with built-in inlet pressure sensors, maintaining a constant flow within the system.

Supported External Modules

Bronkhorst mass flow controller >>

Instrument with a gas database on board which provides real-time temperature and pressure compensation.

Knauer HPLC pump >>

10mL/min or 50mL/min capacity pumps with built-in inlet pressure sensors, maintaining a constant flow within the system.

Eldex Optos HPLC pump >>

Up to 80 mL/min capacity pumps with built-in inlet pressure sensors, maintaining a constant flow within the system.

Vici selector valve >>

High pressure selector valves are used for multi-column, multi-sample, or multi-trap operations.

Brooks AIM3000 Autosamplers >>

Brooks’s module is designed to automate the continuous handling of liquid samples for the Instrument Fleets and the H-Cube® Advance. 3 different sizes can be chosen depending on the user’s needs.

Custom third-party modules

Other third-party devices can also be integrated into the system per user request. If you are interested in the system's compatibilities, reach out to us! Our experts are ready to discuss solutions customized to your application needs.

Do you have questions?

Reach out to us at any time and experience fast and efficient support tailored to your specific needs.