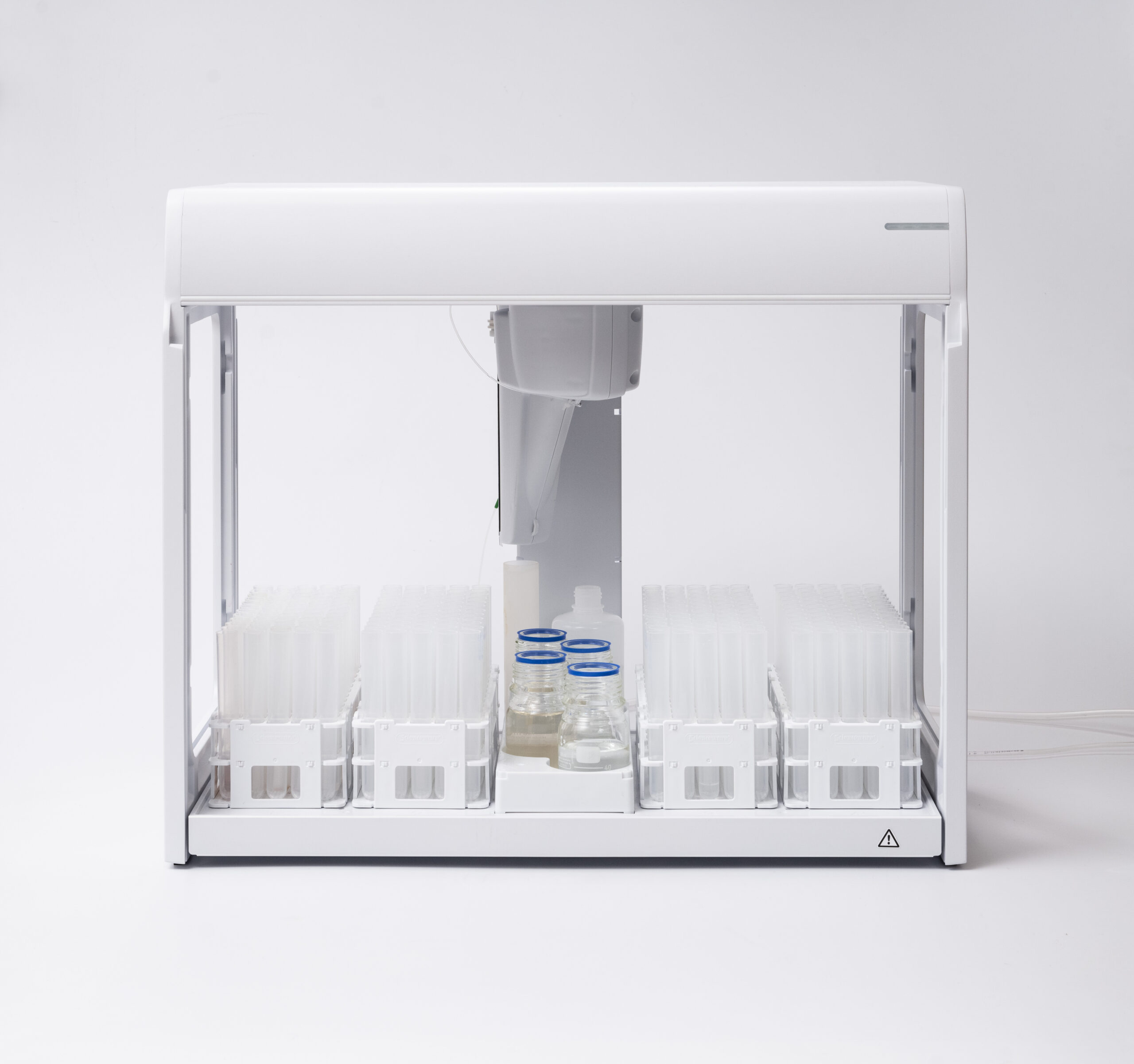

Autosampler for H-Cube® Pro

Automated liquid handler for your system

Learn more about the Brooks AIM4000 Autosampler, your indispensable partner in laboratory automation. This module seamlessly integrates with ThalesNano's H-Cube Pro hydrogenation flow reactor, empowering you to revolutionize your research and streamline your workflows.

Features

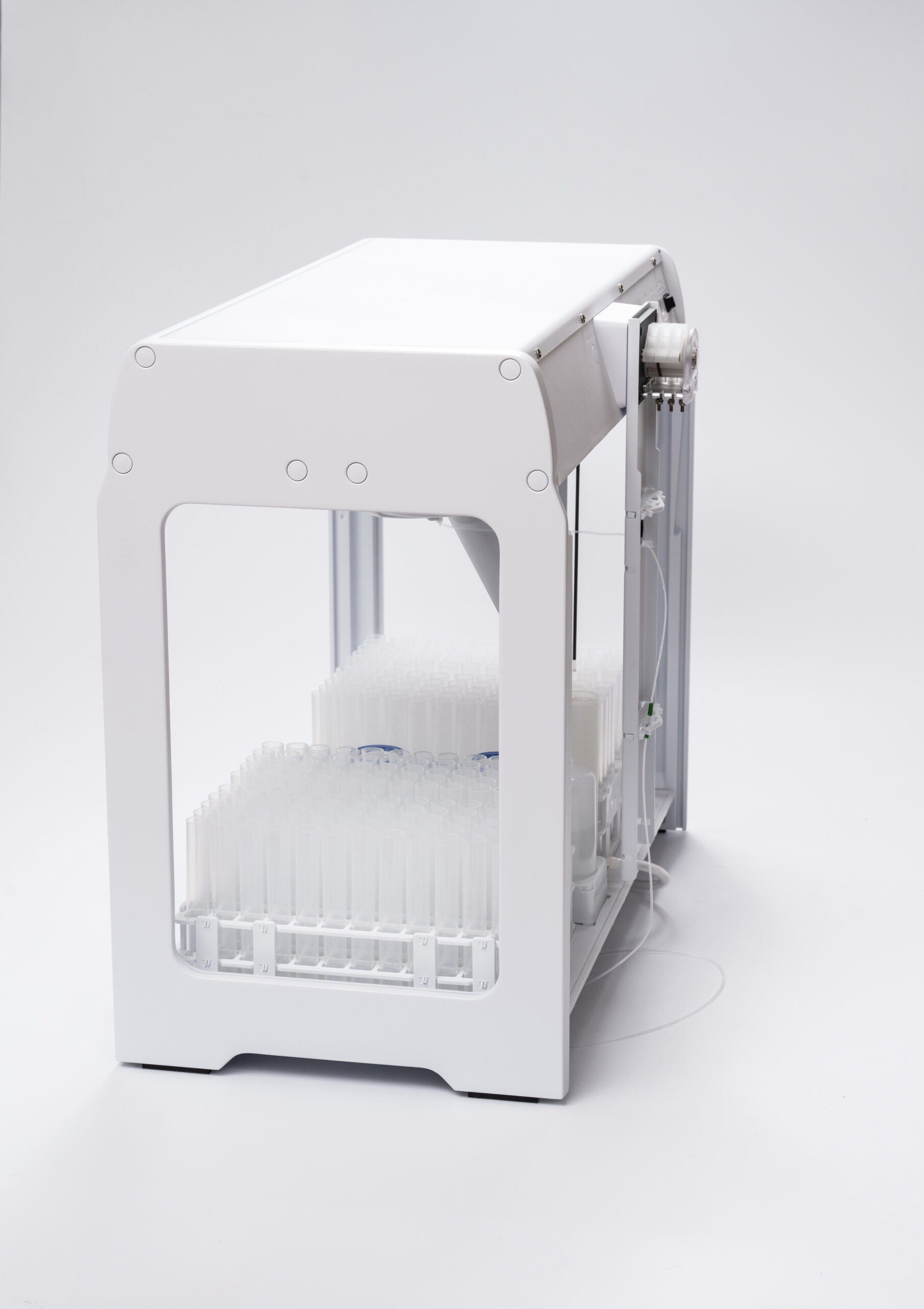

Maximized Efficiency: The AIM4000 boasts a compact footprint, optimizing valuable space for samples and standards. Its proven mechanical design ensures exceptional reliability.

Precision and Purity: Ideal for small-scale applications, the AIM4000's moving probe arm minimizes wear particles, preventing sample contamination. Probe travel is confined within the autosampler's boundaries, leading to faster washout and sampling.

Outstanding Customization: With highly flexible programming capabilities, you control probe speed, depth, travel limits, wash pump speed, and specialized probe moves. The solid, robust design ensures seamless operation.

Portability Meets Durability: Easily transport the autosampler around your lab while benefiting from its high chemical resistance to acids and organic solvents. The protective transparent sampler cover adds convenience without consuming additional space.

Maintenance Made Simple: The AIM4000 is hassle-free and customizable for various application requirements.

Seamless integration with the H-Cube Pro: The AIM4000 works easily with the H-Cube Pro and opens new ways to automate and improve your hydrogenation reactions.

Technical specifications

Footprint: 600 mm x 317 mm (23.6” x 12.5”)

Height: 510 mm (20.1”)

Weight: approx. 15 kg / 33.1 Ibs

Sample Racks: Various options to accommodate your specific needs.

Maximum Vial Height: 150 mm

Power Input: 100 - 240 V, 47 - 63 Hz, 1.5 A

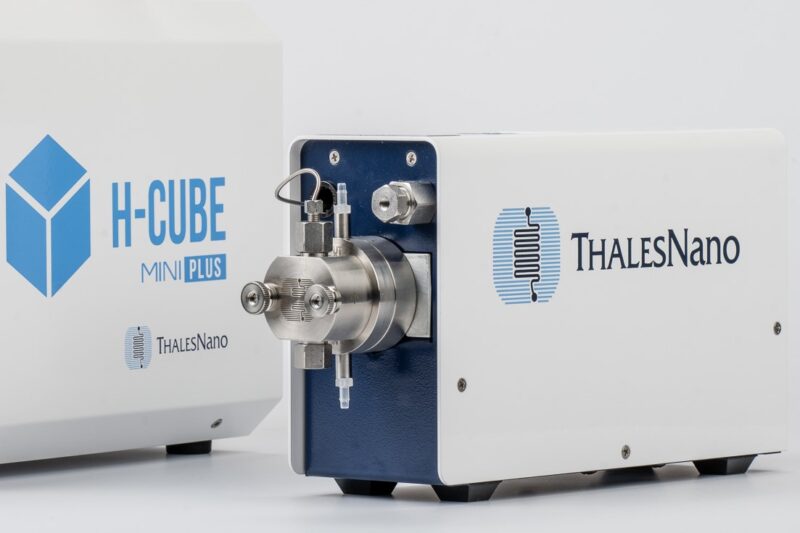

Use the autosampler with the H-Cube Pro

The integration of the H-Cube Pro hydrogenation reactor with Brooks' AIM4000 autosampler has resulted in a seamless partnership, setting a new standard for automated liquid handling in chemical reactions. This synergy grants you unprecedented convenience, efficiency, and speed in optimizing your reactions, all at your fingertips. The liquid handling process is effortlessly controlled through the user-friendly interface of the H-Cube Pro, simplifying the execution of complete reaction sequences.

The H-Cube Pro, purpose-built for advanced hydrogenation and complex flow chemical reactions, offers an extensive range of benefits. It boasts a wider temperature range, higher hydrogen production rate, and increased flexibility, catering to the diverse needs of users. Additionally, the Hastelloy edition of the H-Cube Pro ensures improved chemical resistance for advanced applications. ThalesNano deeply values and appreciates this transformative collaboration, which represents a significant milestone in our mission to empower laboratories worldwide with cutting-edge scientific solutions.

Browse Brooks's Analytical Solutions

Brooks's analytical systems provide advanced automation in application processes, allowing for seamless laboratory workflows. Their systems enable laboratories to achieve efficient, accurate, and reliable results leading improved research outcomes and cost reductions.

Explore the power of automation in chemical synthesis with Brooks's solutions.

Do you have more questions?

Discover the power of automation and precision with the Brooks AIM4000 Autosampler. Elevate your research capabilities and accelerate reaction optimization alongside the ThalesNano H-Cube Pro. Together, they redefine what's possible in your lab.

For more information about the H-Cube Pro and how it complements the AIM4000 Autosampler, please contact us.