High-temperature chemistry

Explore ThalesNano's solutions for high-temperature reactions

Performing high-temperature reactions

In the field of chemistry, precise control over temperature is a critical factor in achieving the necessary activation energy for successful reactions. Traditionally, chemists have faced limitations in reaching high temperatures using batch equipment, typically capping at 250-280°C within a safe operating range. As a result, numerous reactions requiring elevated temperatures have remained inaccessible or required extended reaction times to accomplish desired conversions or yields.

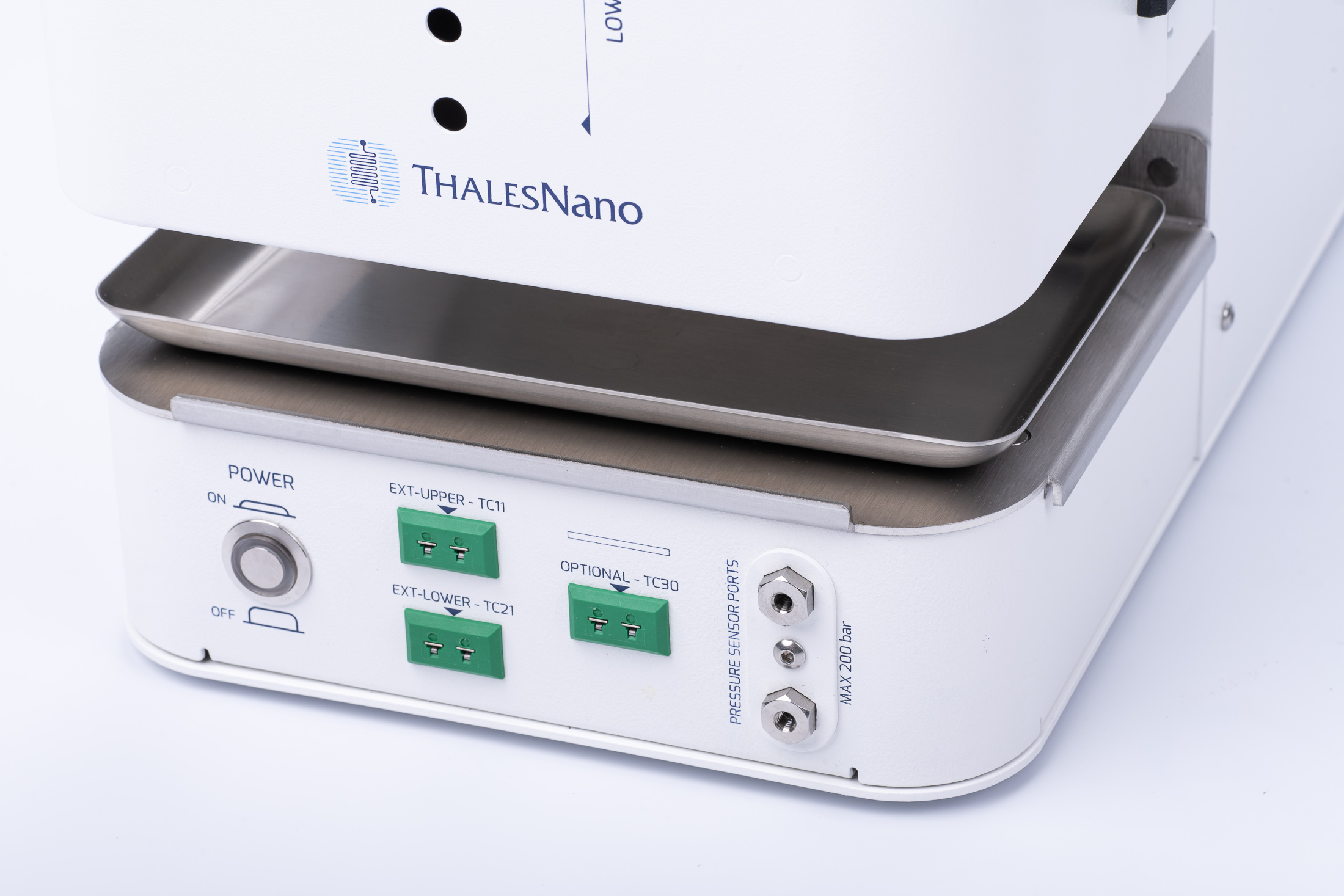

At ThalesNano, we recognized this challenge and set out to develop an innovative solution. We have introduced the Phoenix flow reactor, our high-temperature reactor designed specifically for the demands of modern chemistry. By harnessing the power of flow chemistry methods, the reactor enables precise control of temperature up to 450 °C, allowing chemists to reach and surpass the conventional temperature barrier. With the Phoenix flow reactor, chemists can now explore reactions that demand higher temperatures to activate the desired chemical transformations. Leveraging the fundamental principle described by the Arrhenius equation, where a mere 10 °C rise in temperature doubles reaction rates, our reactor empowers researchers to achieve optimal outcomes with enhanced efficiency and control.

Synthesis of heterocycles

Heterocycles play a pivotal role in both nature and chemical synthesis, making them highly significant in various fields. In the realm of nature, nitrogen-, oxygen-, and sulfur-containing heterocyclic molecules can be found abundantly in all living organisms. These molecules often exhibit specific biological effects, distinctive aromas, or vibrant colors, capturing the attention of the modern chemical industry, particularly pharmaceutical companies, which strive to produce these materials.

To produce novel heterocycles, there are two primary approaches. The first involves leveraging nature itself by extracting pre-existing heterocycles from plants and animals. The second method involves total synthesis, wherein these molecules are constructed from small organic or inorganic components. ThalesNano is dedicated to assisting chemists in pushing beyond the chemical space accessible through conventional batch methods, facilitating the synthesis of new compounds.

The synthesis of heterocycles dates back to the early 1800s, and today, numerous well-established pathways exist for the production of common heterocyclic compounds. Many of these reactions necessitate elevated temperatures, catalysis, and the addition of acids or bases to yield the desired products. However, performing these reactions using traditional batch methods can be hazardous, and the reaction scale often relies heavily on the volume of the reaction vessel.

ThalesNano's advanced reactors provide a solution by enabling these reactions to be conducted in a continuous manner, ensuring precise control over pressure, temperature, and residence time within a safe environment.

Substitution reactions

Substitution reactions have long been employed in organic chemistry as effective means for introducing or replacing functional groups in aromatic or aliphatic organic molecules. Depending on the behavior of the leaving group, these reactions can be carried out in either a catalytic or non-catalytic environment. Substitution reactions offer valuable pathways for creating new molecules and even entire libraries of diverse structures.

The production rate of continuous flow reactions relies on the catalyst's longevity when performed under catalytic conditions. In the absence of catalysis, productivity is determined solely by the reaction time. As a result, continuous flow solutions for substitution reactions present compelling advantages, particularly for industrial applications.

ThalesNano recognizes the potential of high-temperature substitution reactions and has developed dedicated continuous flow systems to address these challenges. Our advanced reactors provide precise temperature control, allowing chemists to explore a wide range of substitution reactions at elevated temperatures, thereby expanding the scope of accessible chemical space.

Browse our application notes

Explore our comprehensive range of application notes and discover how the Phoenix flow reactor revolutionizes high-temperature chemistry. Gain a deeper understanding of reaction mechanisms, safety considerations, and optimized reaction conditions that enable efficient and controlled high-temperature synthesis.

Flow reactors can be utilized to implement high temperature and high pressure chemical reactions. With this, chemists can move towards extending the accessible chemical parameter space to access new molecules and applications.

Ionic liquids have gained great interest during the last three decades due to their green and sustainable behavior along with their added versatility as solvents. N-Alkylimidazole derivatives are key intermediates for the synthesis of quaternary ionic liquid salts.

This application note evaluates the performance of the Phoenix flow reactor and the Gas Module in the production of value-added chemicals (other than methane) from a low-cost renewable carbon dioxide source.

Modern flow chemistry methods offer new chemical space for drug discovery programs: novel compounds can be synthesized in dedicated high temperature/high pressure (high T/p) reactors, while reaction times can be shortened dramatically.

In this application note, we demonstrate the flexibility of the Phoenix Flow Reactor by presenting various applications such as N-substitution, thermal Boc-removal, scalable Claisen-rearrangement, and synthesis of soluble polyphosphate anions.

Read related publications

Discover our scientific publication selection to learn more about high-temperature chemistry in continuous flow.

Sign up for our Newsletter for More Information

Do you have questions?

Reach out to us at any time and experience fast and efficient support tailored to your specific needs.