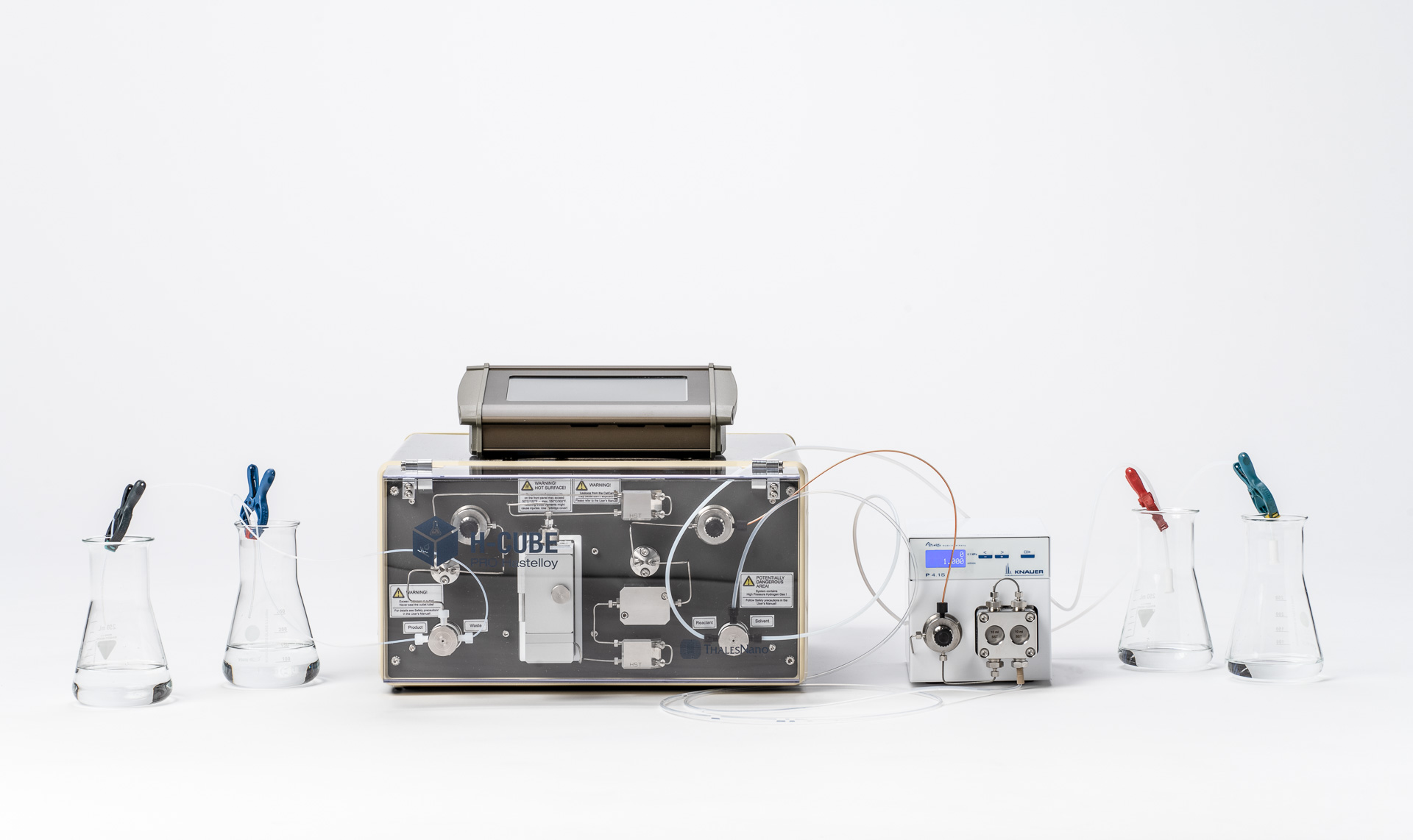

H-Cube® Pro Hastelloy

Continuous flow hydrogenation reactor for advanced chemistry

On-demand Hydrogen Generation and High Chemical Resistance

The H-Cube® Pro Hastelloy hydrogenation flow reactor is designed to extend the available reaction space of its renowned stainless steel counterpart, the H-Cube® Pro. All wetted parts are made from Hastelloy C for improved chemical resistance. With the H-Cube® Pro Hastelloy, working with corrosive reagents becomes as easy as any other reaction with the H-Cube® product family.

Extend your Chemical Synthesis Capabilities

If you're interested in chemical syntheses beyond hydrogenation, we highly recommend ot newest flow reactor, the H-Cube® Advance Hastelloy. Aside from hydrogen, the instrument can conduct experiments with 13 other gases via the built-in mass flow controller and the external gas inlet, moreover, its Hastelloy C tubing allows for reactions with corrosive reagents. Despite its advanced capabilities, operating the module is easy due to its user-friendly interface.

Features of the H-Cube Pro Hastelloy

- Hastelloy C pump head

- Hastelloy C tubing

- Hastelloy C CatCart® columns with a wide range of heterogeneous catalysts

- No need for hydrogen cylinders, as hydrogen is generated on-demand by the system from water

- Wide temperature range (10-150 °C)

- Wide pressure range (from atmospheric pressure to 100 bar)

- No catalyst handling with pre-filled CatCarts®

- High throughput

- Great reaction control

How does the H-Cube Pro Hastelloy work?

- Hydrogen is generated by the electrolysis of water inside the system.

- The microHPLC pump delivers pure solvent into the system, where it is mixed with hydrogen using a mixing valve.

- The gas-liquid mixture progresses into the reaction zone where the system controls to the user defined reaction conditions (pressure, temperature, and flow rate).

- Once the desired parameters are achieved and the reaction zone achieves stablity, the feed can be switched from the solvent to the reactant solution.

- The reaction mixture passes through a CatCart® (a pre-packed column containing solid catalyst), where the reaction takes place. The product leaves the CatCart®, but the catalyst is retained.

- The product is collected in the collection vial.

- Reactions from milligrams to grams can be performed.

Applicable corrosive reagents

- Mineral acids and bases

- Strong oxidizers (such as ferric and cupric chlorides)

- Nitric, formic and acetic acids, acetic anhydride

- Wet chlorine

- Sea water and brine solutions

- Hypochlorite and chlorine dioxide solutions

System Specifications of the H-Cube Pro Hastelloy

| Technical data | |

|---|---|

| Temperature range | From 10 to 150 °C |

| Pressure range | Atmospheric pressure to 100 bar |

| Liquid flow rate | 0.1 – 3 mL/min |

| Optimal liquid flow rates | 0.5 – 2 mL/min |

| Maximum hydrogen production rate | 60 Nml/min (in 100% Bub. Det. Mode) |

| Required water specifications | Deionized water with recommended conductivity of 14 MΏcm |

| Dimensions | Height: 40 cm (15.75”) (including touch screen); width: 37 cm (14.6”); depth: 51 cm (20.1”) |

| Weight | 23 kg (46.3 lbs)/td> |

| Power requirements | 115-230 VAC; 5A/115 VAC; 2.5A/230 VAC; 47-63 Hz, 300 W |

| Water reservoir capacity | 300 mL/td> |

Availability based on Region

It varies whether an H-Cube® Advance Hastelloy or an H-Cube® Pro Hastelloy can be purchased based on the user's country/region. Please contact us to learn which instrument is available in your region.

Do you have questions?

Reach out to us at any time and experience fast and efficient support tailored to your specific needs.