Instrument Fleets

Simultaneously control your parallel processes

Scalable Platform for Multi-phase Catalytic Reactions

Unlike standalone flow reactors, ThalesNano’s Instrument Fleets offer a highly customizable, scalable solution to perform reactions at high pressures and temperatures. The system consists of multiple flow reactors, hydrogen generators, gas and liquid inputs, making it suitable for conducting kg-scale reactions while maintaining a small footprint and its ease of use.

Features of the Instrument Fleets

Modular: The system can be customized according to the user’s reaction types, including multi-step synthesis.

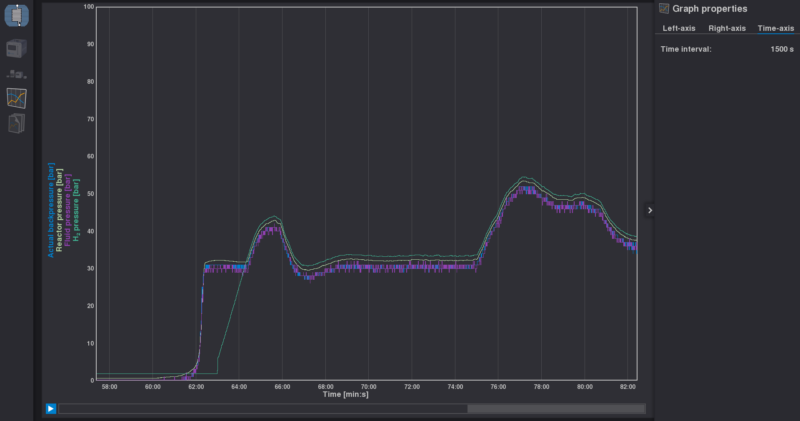

Precise parameter-handling: Seamless control and monitoring of gas and liquid flow rates, temperatures, and pressures of multicomponent experiments.

Automation: Reaction steps can be fully and securely automated by incorporating application-based fleet-wide safety triggers.

Realistic modeling: Simulating a production-scale experiment in flow gives an accurate picture of the reaction in the development phase.

On-demand hydrogen: Generates hydrogen in-situ, on-demand by water electrolysis, eliminating the need for hydrogen cylinders and improving lab safety.

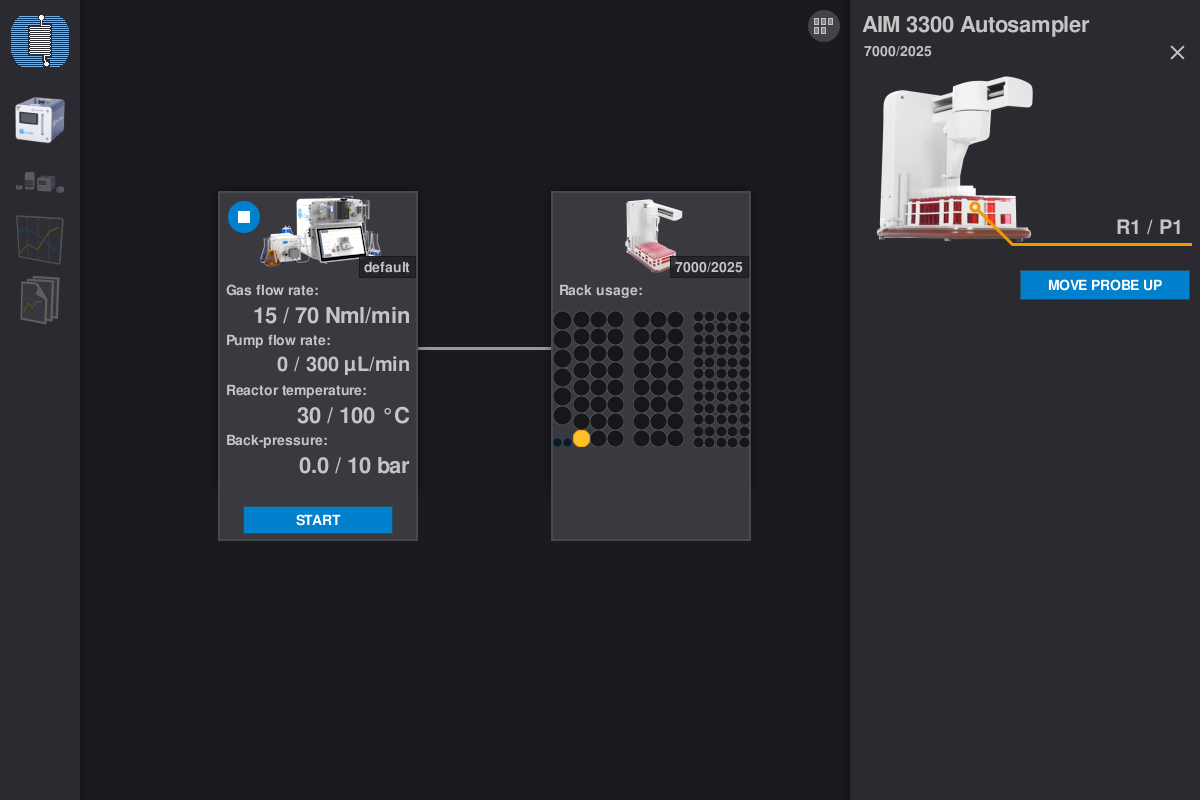

Simultaneous parallel experiments: Multiple platforms for different applications can be controlled from a single user interface.

Remote Control and Monitoring

ThalesNano's Instrument Fleets can be effortlessly controlled through the THS System Controller® and THS ReAction® Software. Therefore, a wide variety of custom configurations are possible and completely tailored to the researchers' needs.

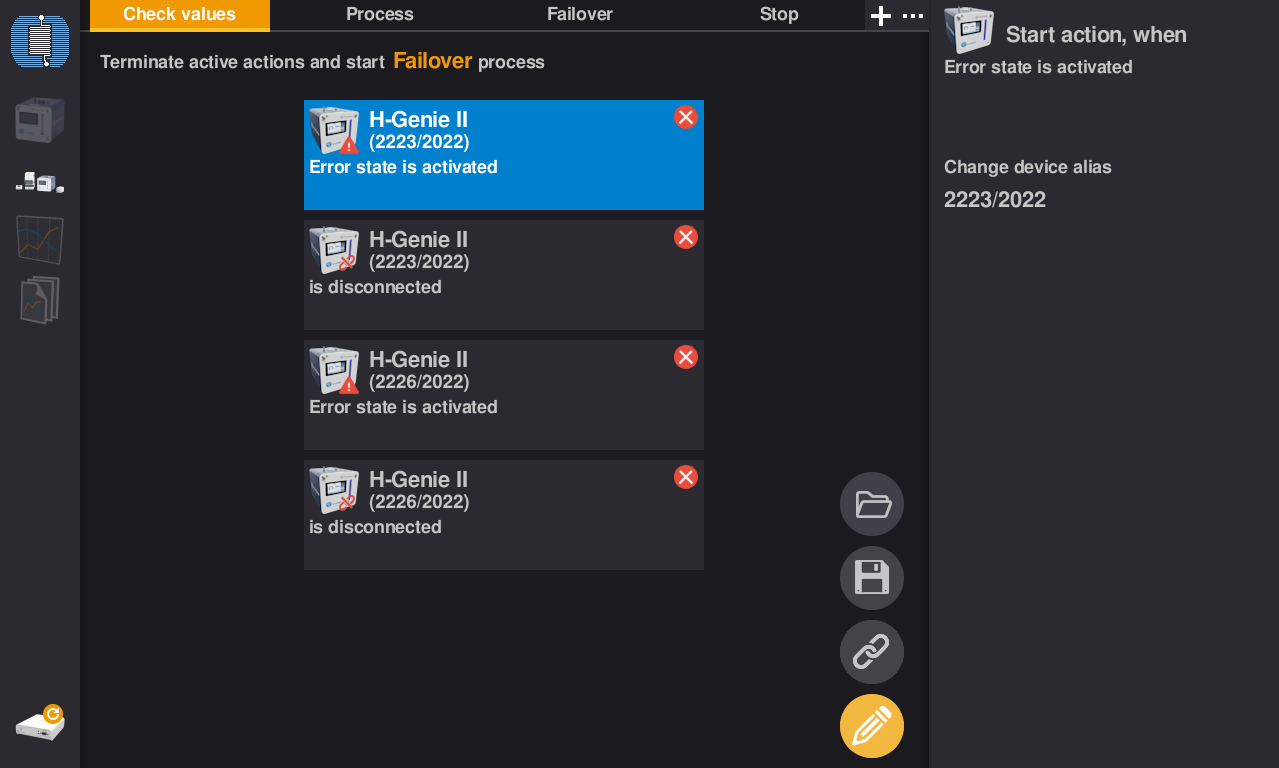

Aside from standalone reactors and systems, THS ReAction® can operate consecutive, parallel, and failover fleets as well, making it suitable for laboratory optimization and scale-up processes.

THS System Controller® >>

Enables communication between all connected devices within the fleet. Its software counterpart, THS ReAction® Software, allows for precise operation of the entire fleet from a single screen.

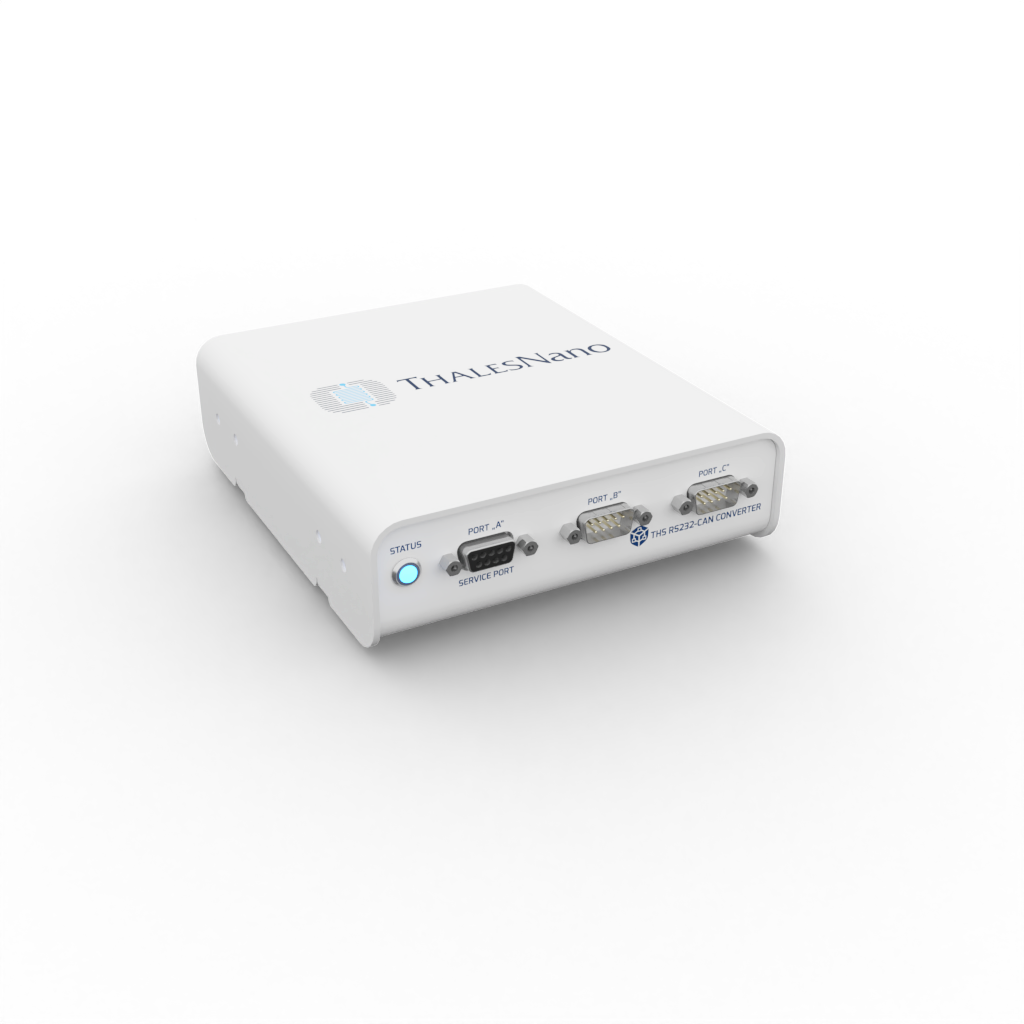

THS RS232-CAN Converter

Designed to connect external modules, such as HPLC pumps, mass flow controllers, and autosamplers to the fleet through the THS System Controller.

Recommended Modules for Fleet Configurations

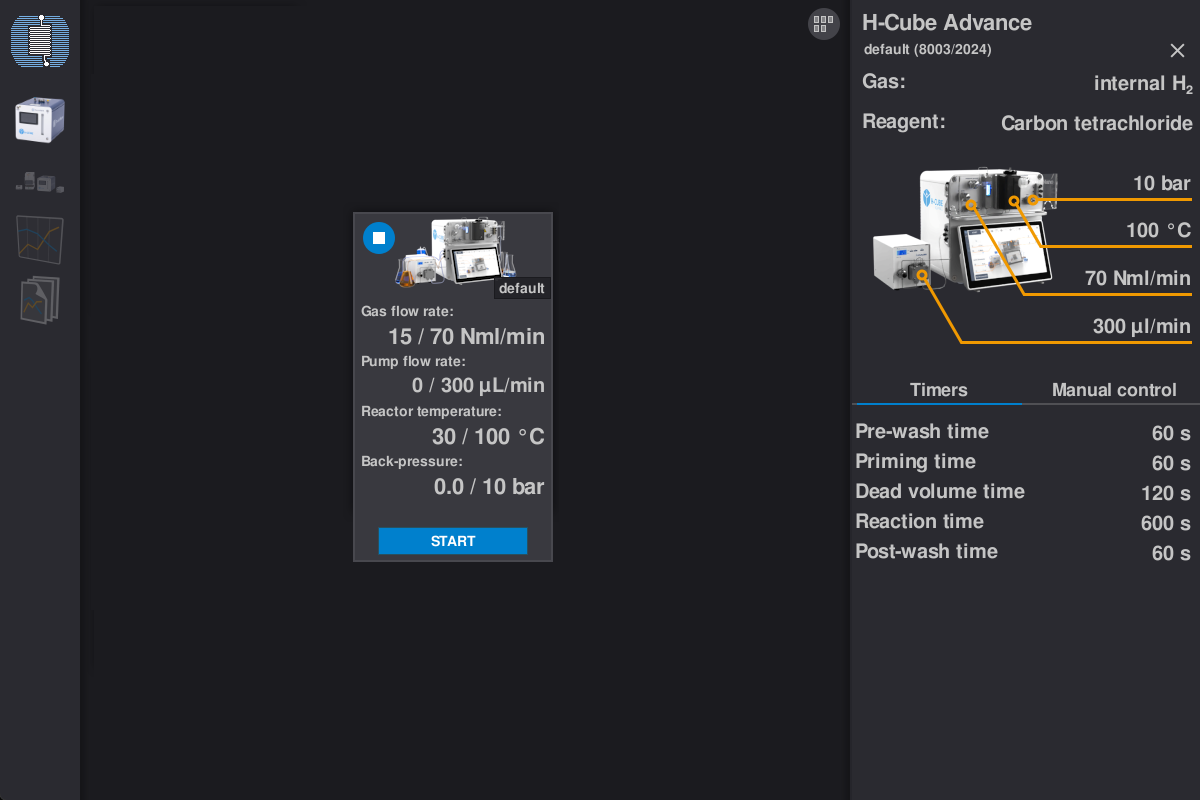

H-Cube Advance

Autosampler

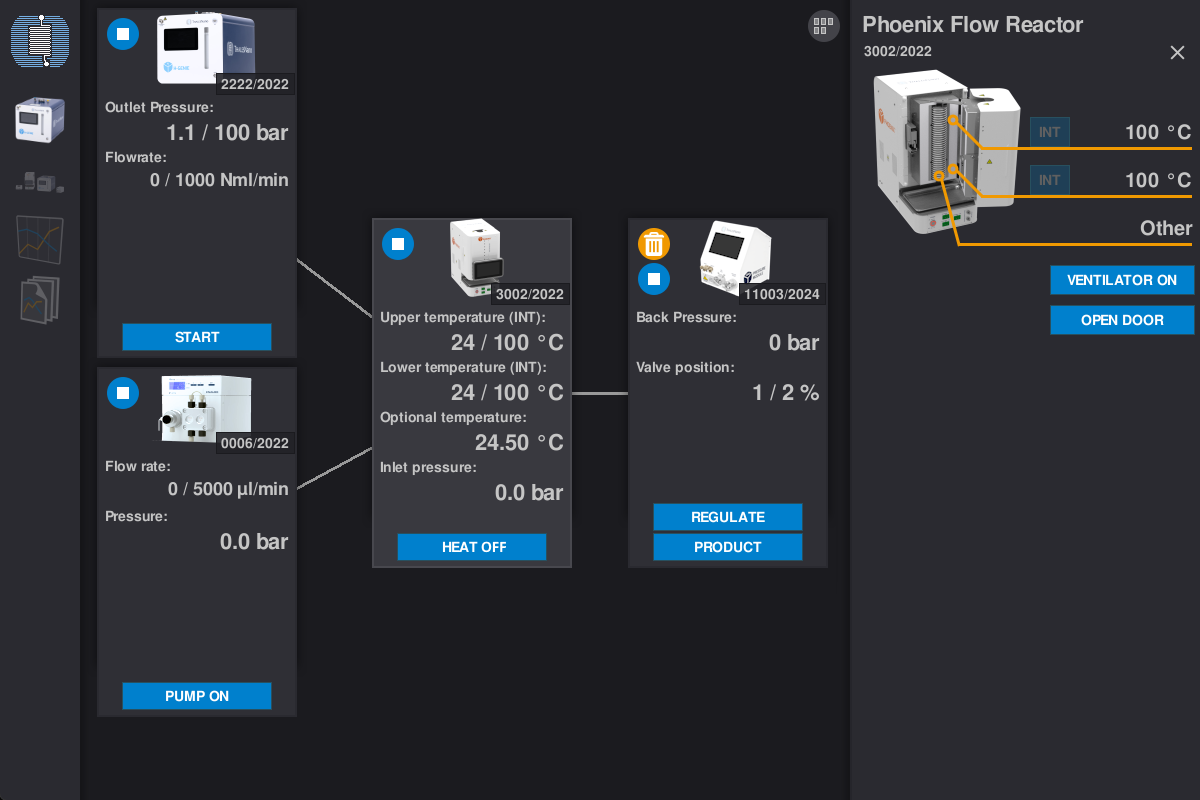

Manual operation mode

Phoenix pro system

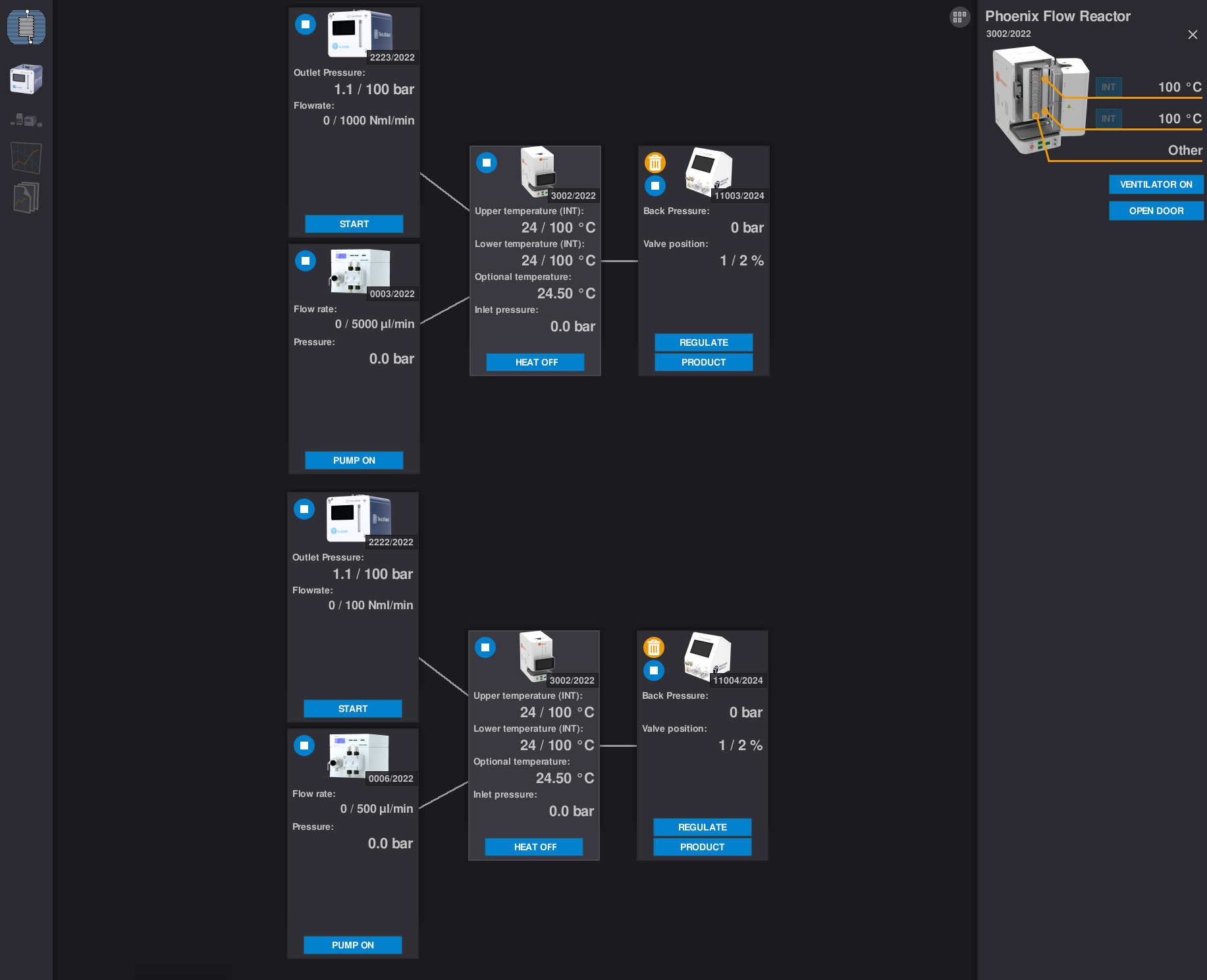

Parallel Phoenix systems

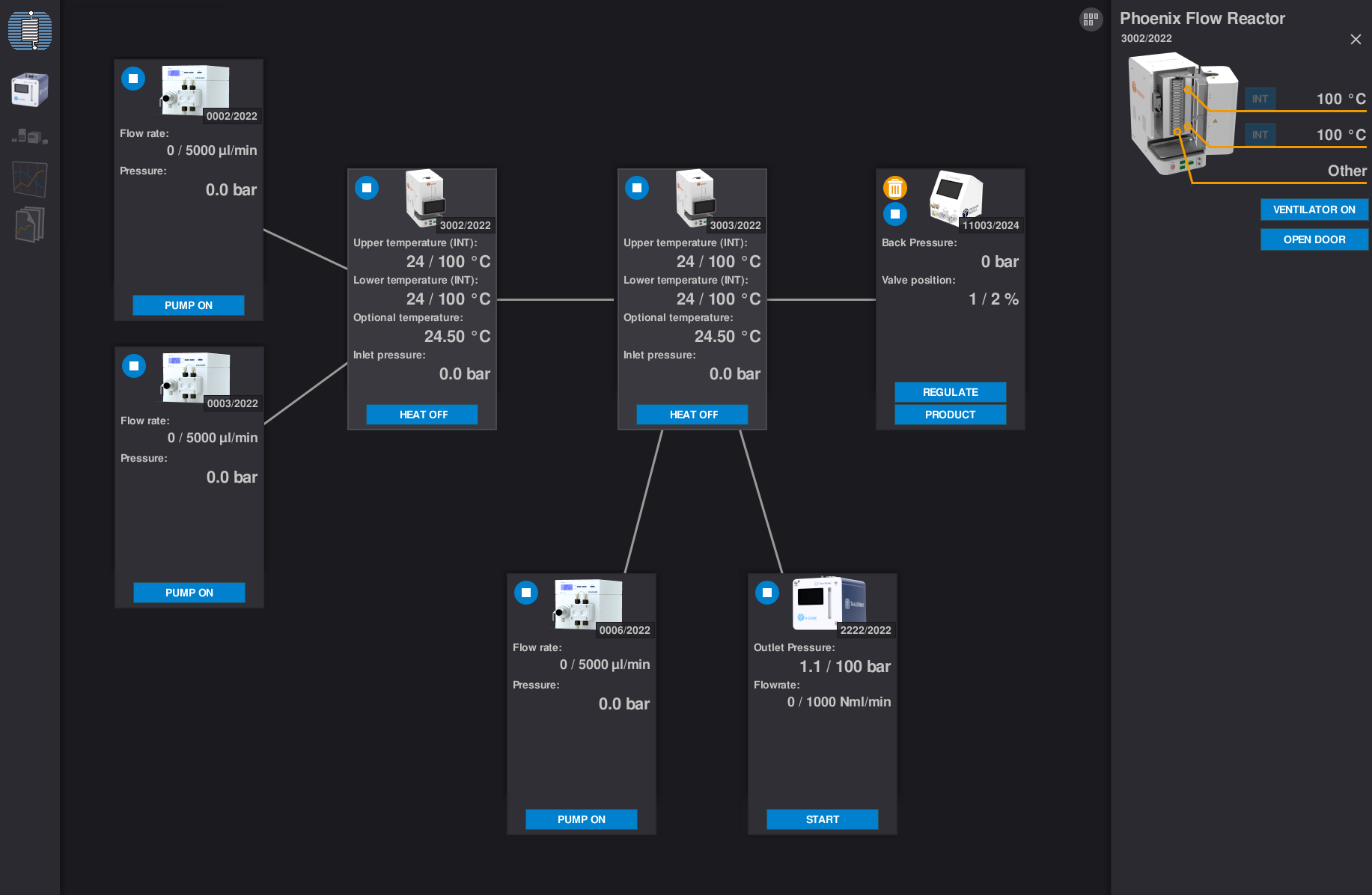

Consecutive Phoenix systems

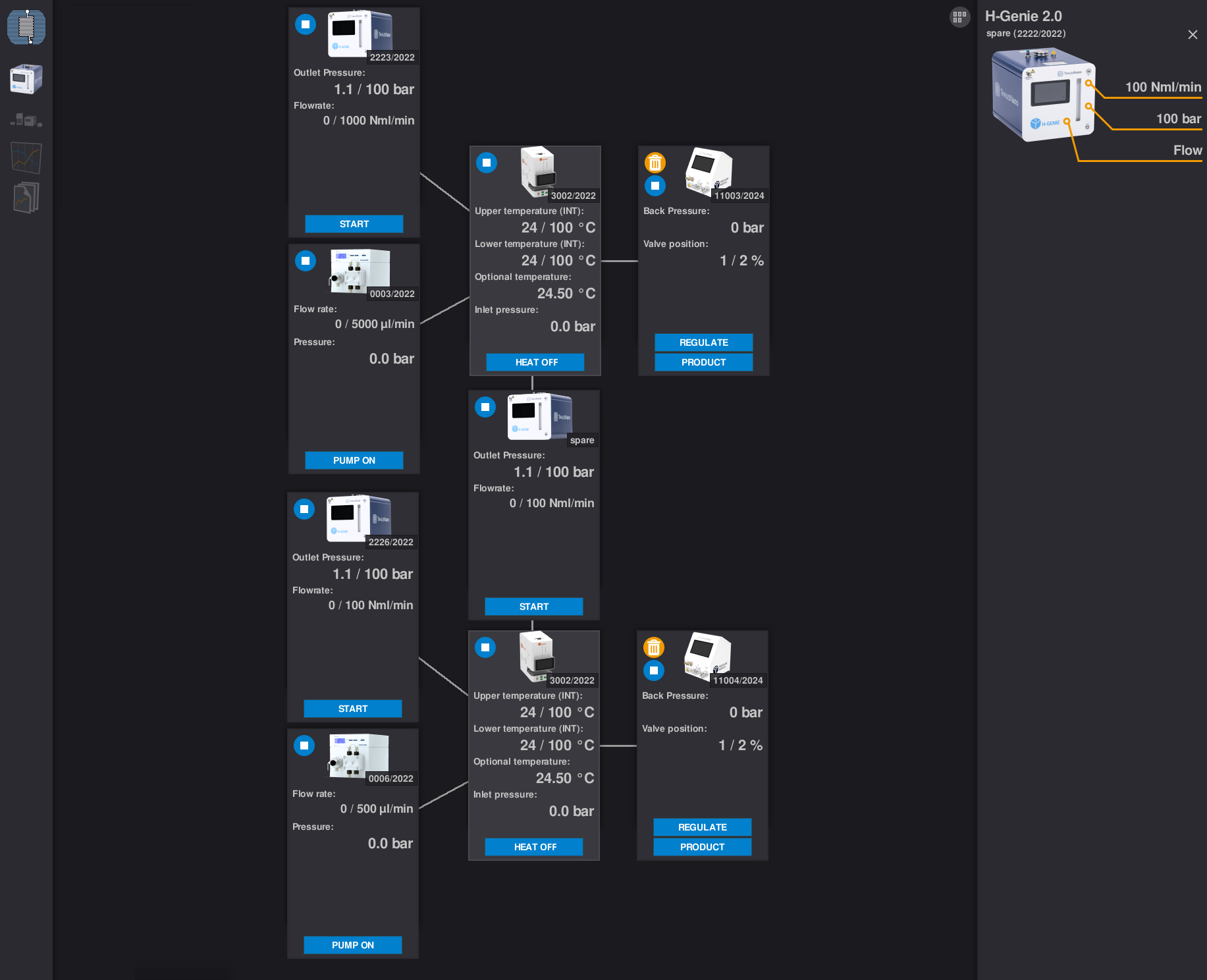

Failover operation mode

Failover sequence

ThalesNano Modules of the Instrument Fleets

Phoenix Flow Reactor >>

High-performance flow reactor with an extended parameter window (temperature up to 450°C, pressure up to 200 bar), enabling the synthesis of novel compounds.

H-Cube® Advance >>

New generation flow reactor, built for heterogeneous catalytic reactions. Produces hydrogen on-demand with flow rates up to 70NmL/min, at temperatures between 0-150°C and pressures up to 100 bar.

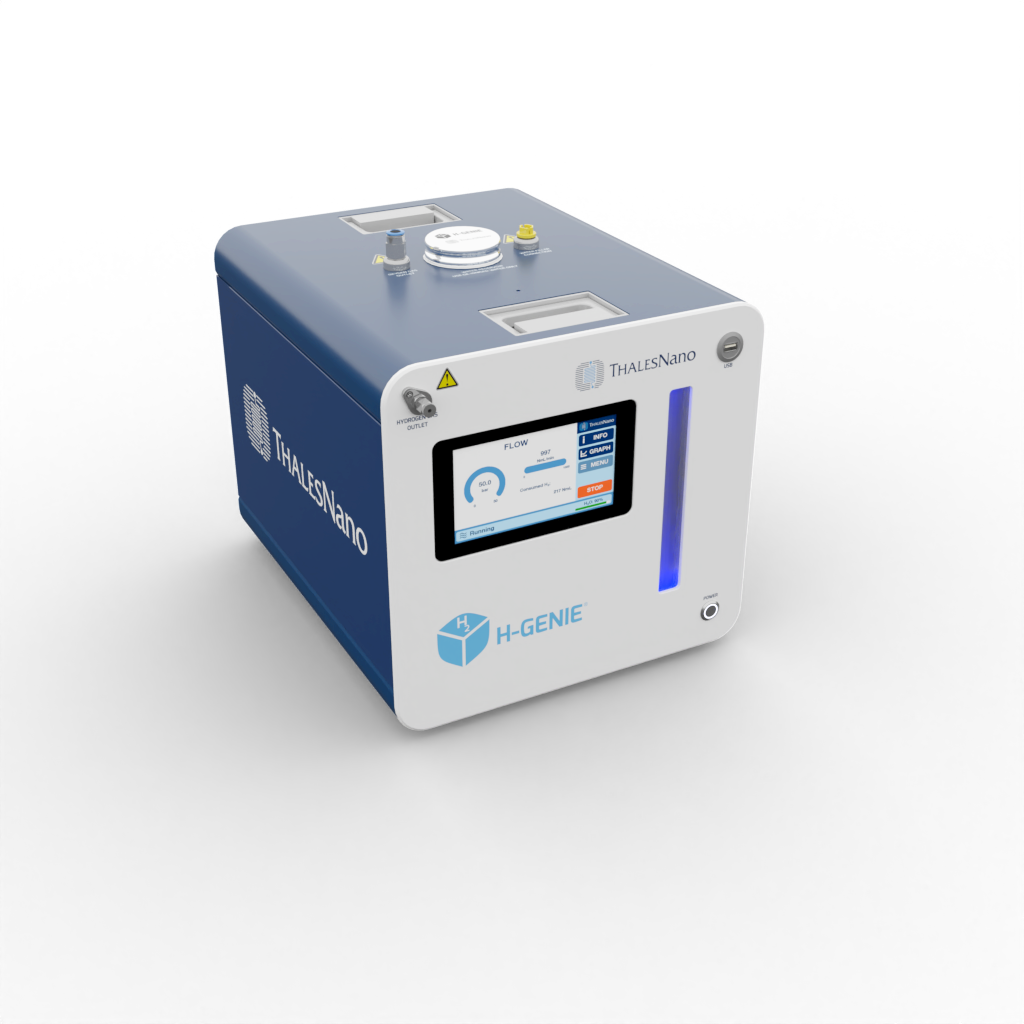

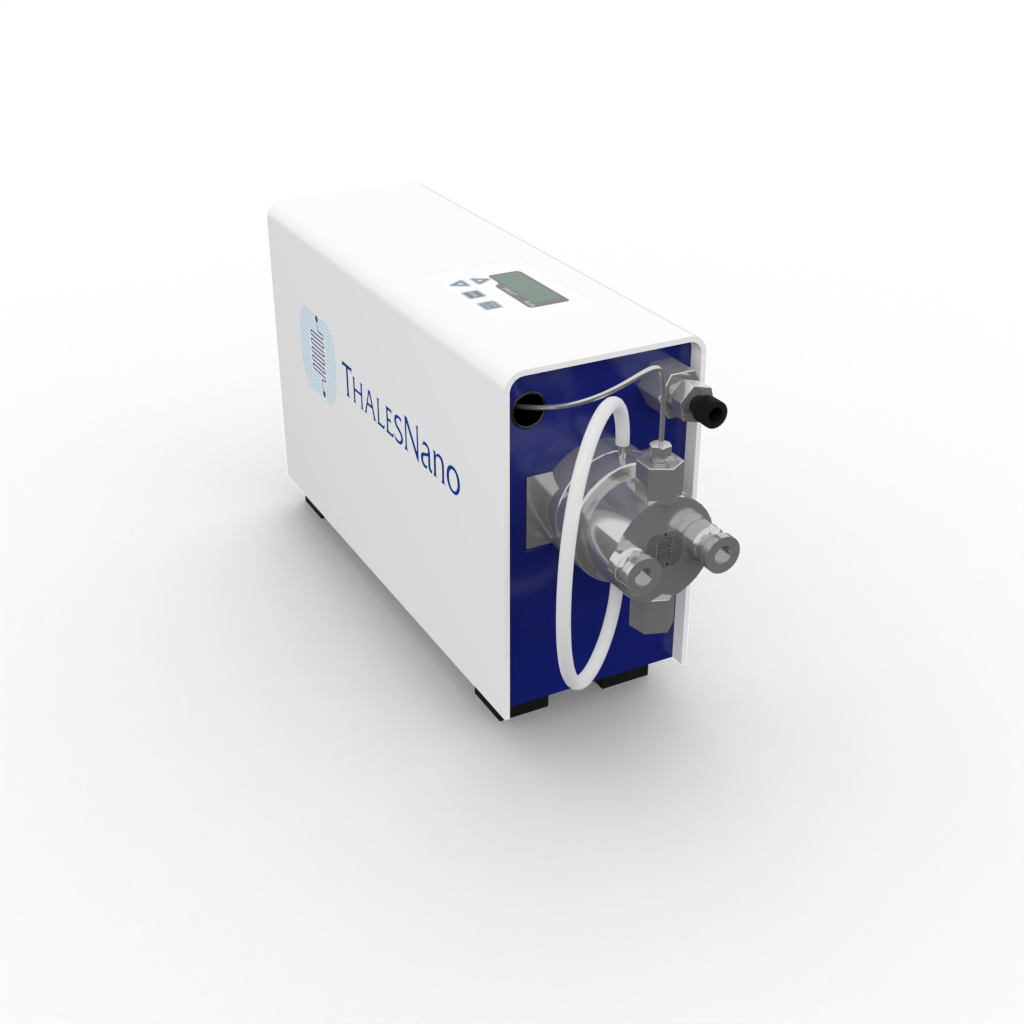

H-Genie® >>

On-demand, high pressure (up to 100 bar) hydrogen generator, producing 99.99% (4.0) pure hydrogen gas via water electrolysis, with flow rates up to 1NL/min.

H-Genie® Lite >>

On-demand, high pressure (up to 50 bar) hydrogen generator, producing 99.9% (3.0) pure hydrogen gas via water electrolysis.

Gas Module / Gas Module Plus >>

Designed for the precise dosing of 14 different gases at flow rates up to 1NL/min and up to 100 bar pressure.

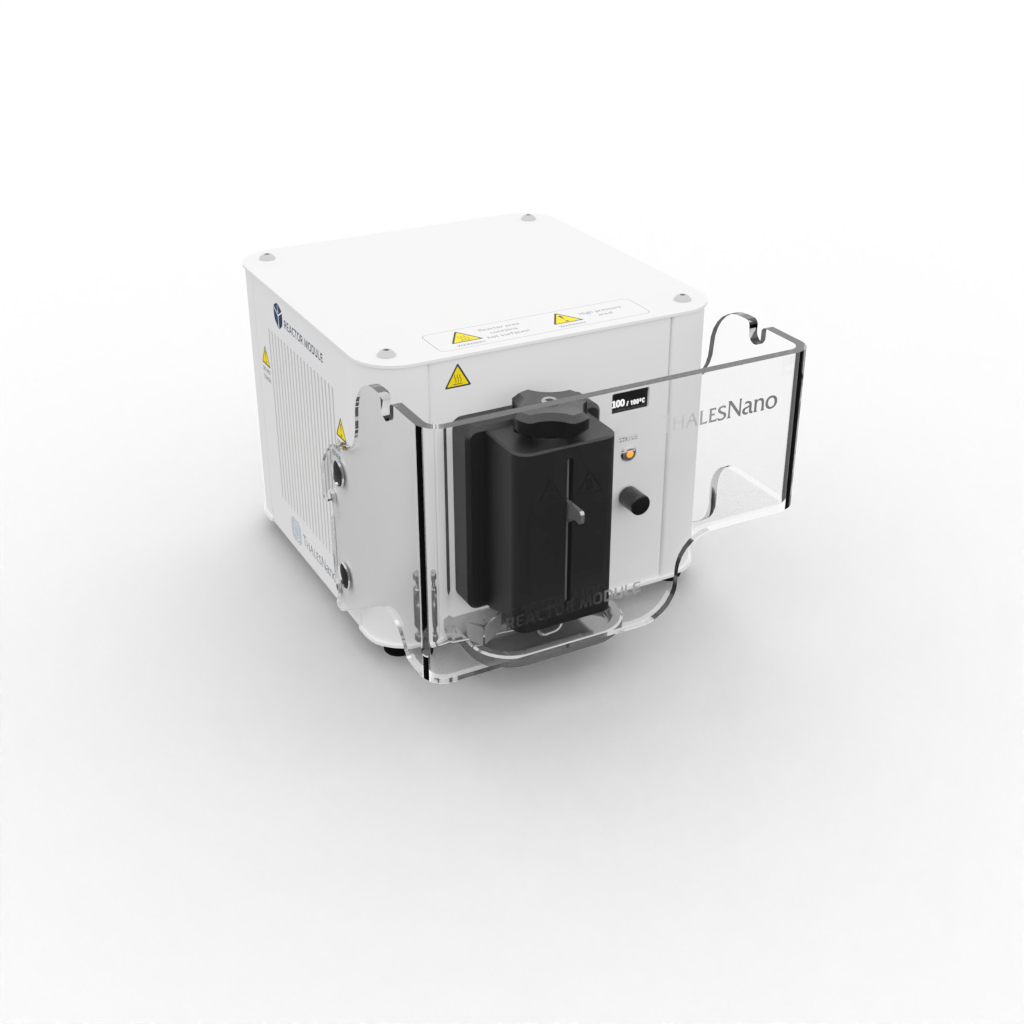

Reactor Module >>

High-temperature, high-pressure reactor unit for catalyst testing, catalyst screening, and multi-step reactions.

Pressure Module 2 >>

New generation motorized back pressure regulator with a built-in pressure sensor. System pressure can be set up to 200 bar and pressure levels can be seamlessly monitored.

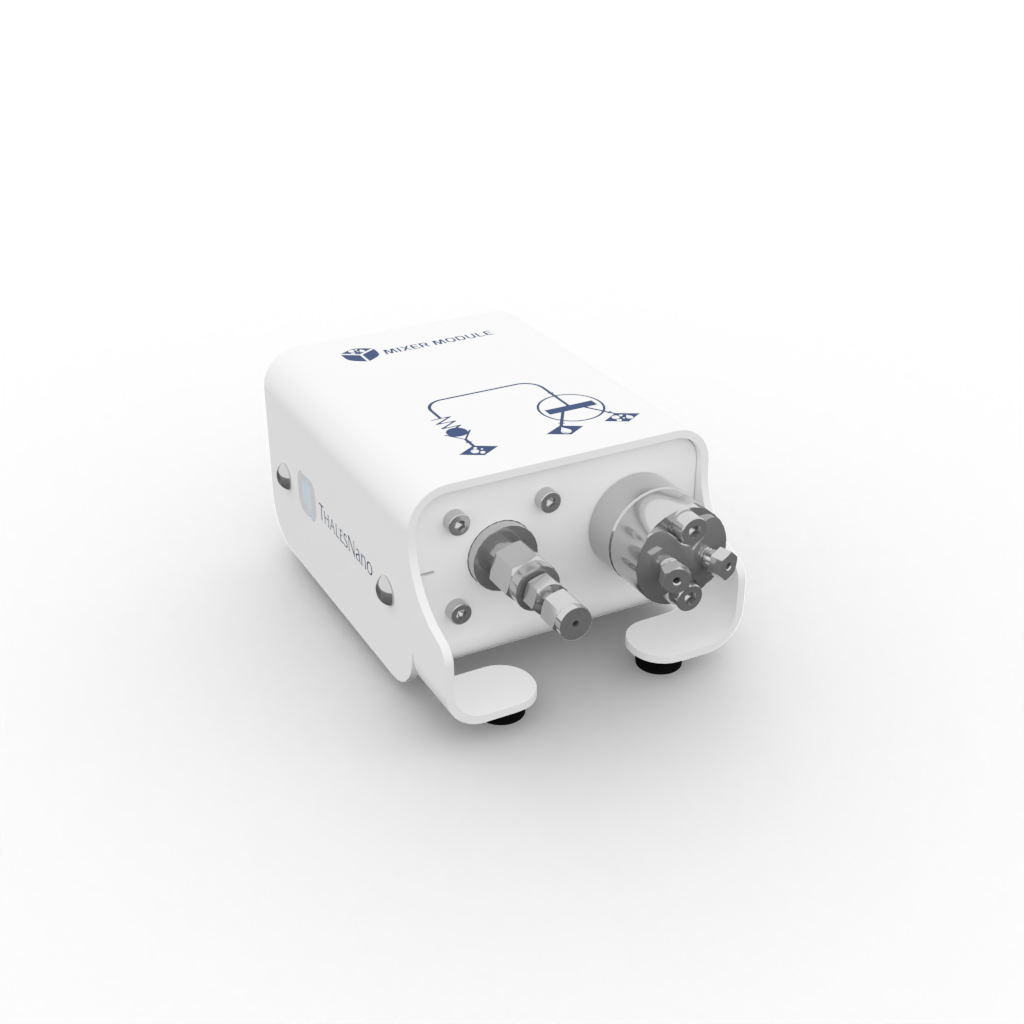

Mixer Module >>

High-performance static mixer for gas-liquid mixtures. Operates up to 200 bar and supports a wide variety of gases and liquids.

ThalesNano Micro HPLC pump

3 mL/min or 10 mL/min capacity pumps with built-in inlet pressure sensors, maintaining a constant flow within the system.

Supported External Modules of the Instrument Fleets

Bronkhorst mass flow controller >>

Instrument with a gas database on board which provides real-time temperature and pressure compensation.

Knauer HPLC pump >>

10mL/min or 50mL/min capacity pumps with built-in inlet pressure sensors, maintaining a constant flow within the system.

Eldex Optos HPLC pump >>

Up to 80 mL/min capacity pumps with built-in inlet pressure sensors, maintaining a constant flow within the system.

Vici selector valve >>

High pressure selector valves are used for multi-column, multi-sample, or multi-trap operations.

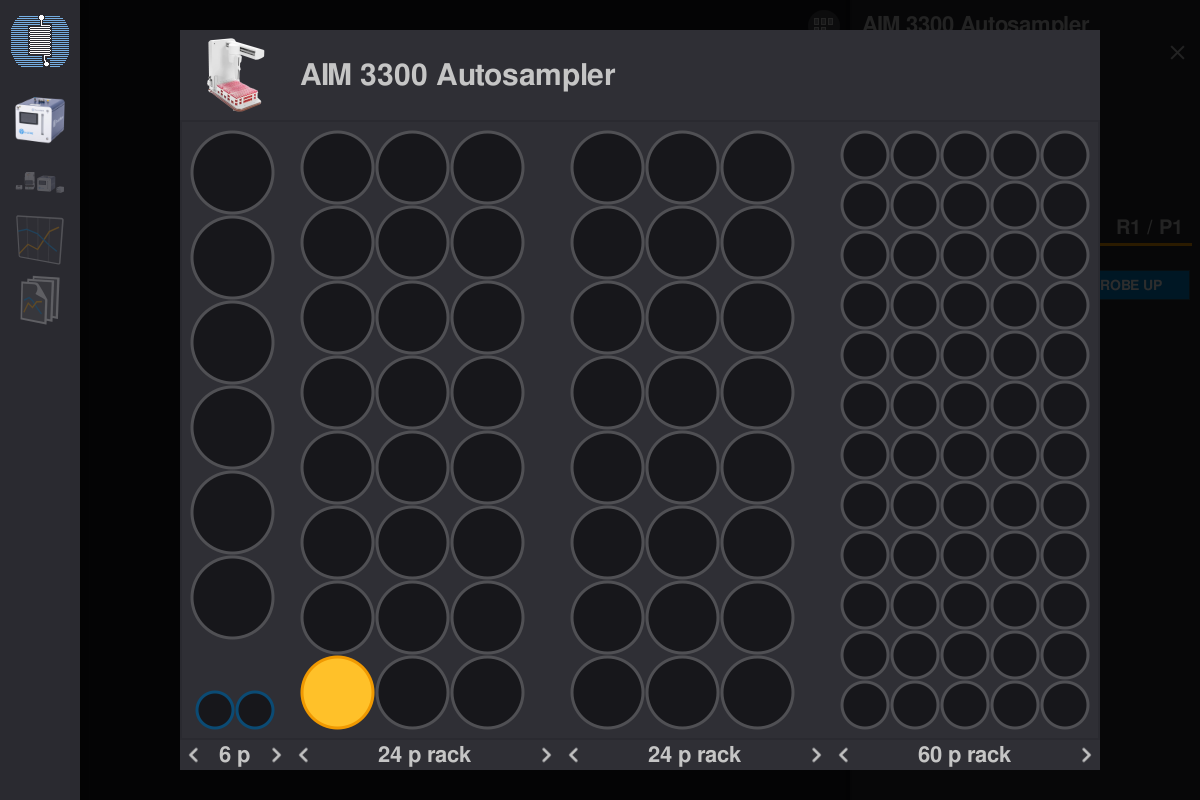

Brooks AIM3300 Autosampler >>

Brooks’s module is designed to automate the continuous handling of liquid samples for the Instrument Fleets and the H-Cube® Advance.

Custom third-party modules

Other third-party devices can also be integrated into the system per user request. If you are interested in the system's compatibilities, reach out to us! Our experts are ready to discuss solutions customized to your application needs.

Applications

Pharmaceutical

- Hydrogenation: Addition of hydrogen to organic compounds to enhance drug effectiveness or to create new drug intermediates.

- Nitro group reduction: Conversion of nitro groups into amino groups to synthetize amines.

- Nitrile group reduction: Conversion of a nitrile group into other functional groups like animes and aldehydes.

- Deuteration: Substitution of hydrogen with deuterium to alter a drug’s metabolism and pharmacokinetic properties.

Petrochemical

- Hydrodenitrogenation: Removal of nitrogen from feedstocks and petrol/fuel-related mixtures.

- Hydrodesulfurization: Removal of sulfur from feedstocks and petrol/fuel-related mixtures.

- Dearomatization: Saturation of aromatic compounds in feedstocks.

- Hydrocracking: Hydrogenolytic cleavage of C-C bonds into smaller fragments.

- Isomerization: Rearrangement of carbon chains into branched compounds.

Sustainable Chemistry

- CO2 capture: Conversion of carbon dioxide into fuels and organic solvents to reduce greenhouse effect and enhance climate neutrality.

- Valorization: Conversion of waste materials or biomass into valuable chemicals and fuels.

- Biofuel synthesis: Conversion of natural compounds like alcohols and sugars into hydrocarbons, resulting in sustainable biofuels.

- Petrochemical additives: Synthesis of useful additives to improve fuel efficiency and increase fuel octane number to reduce emissions and harmful combustion side products.

- Rubber waste reduction: Hydrogenation and thermal treatment of rubber waste to valorize problematic materials.

Do you have more questions?

ThalesNano's goal is to make flow chemistry technology easily accessible to researchers worldwide. If you have any questions or need any support, reach out to us at any time. Our experts will get back to you shortly to discuss your needs.