Petrochemistry

The Pathway to Sustainable Petrochemical and Biofuel Development

Petrochemistry - ThalesNano

Overview

The petrochemical industry produces chemicals like ethylene and benzene, derived from petroleum and natural gas, which are essential in many fields that contribute to our modern life. Widely known for utilizing waste and greenhouse gases to create renewable fuels from biomass, the sector aims to replace fossil fuels, and is making active contributions to agriculture, automotive, and aviation industries.

The development phase often proves to be difficult, as firms in this industry have to face higher production costs compared to ones using traditional fuels with a preestablished infrastructure. They also apply inefficient synthetic methods which make product development prone to trial and error. To mitigate these risks, ThalesNano's continuous flow chemistry technology offers a solution by providing a wide parameter window, enabling difficult transformations, and making experiments more reproducible by achieving efficient mixing.

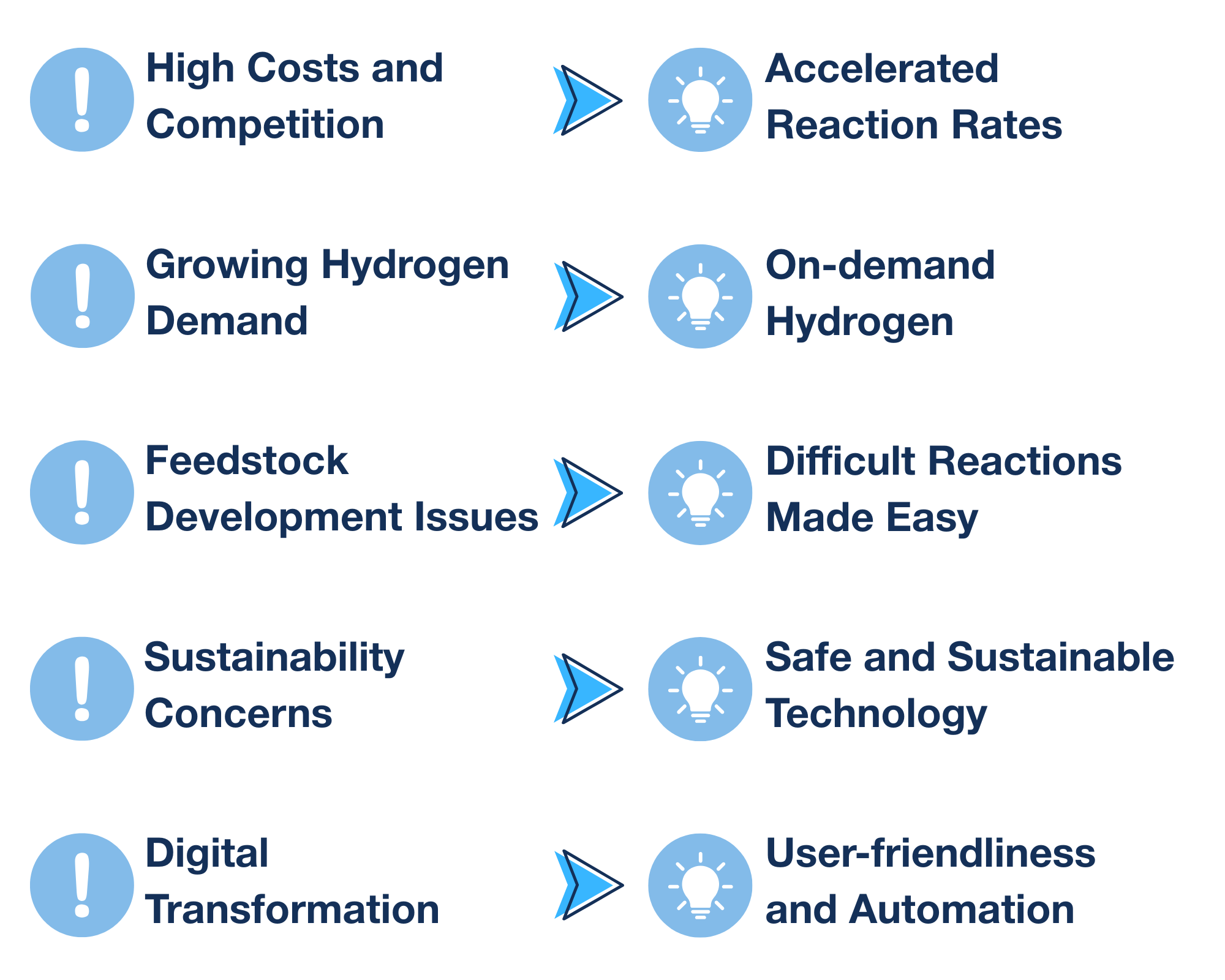

Challenges in Petrochemistry

As concerns about the climate rise, so does the pressure on the petrochemical industry. Firms in the sector have to find ways to reduce their carbon footprint and implement greener processes while tackling the high production costs of bio-based materials and the operational complexity of newly implemented technologies.

High Costs and Competition

Albeit being a greener solution, biofuels must compete with traditional fuels which have a pre-established infrastructure and lower production costs. The commercialization of biofuels needs expensive feedstocks, advanced technologies, and the implementation of large-scale infrastructure.

Growing Hydrogen Demand

Hydrogen gas is essential for petroleum refining, mainly through hydrocracking and hydrotreating processes. Adding hydrogen to crude fuels reduces CO2 emissions, making major contributions to sustainable practices. However, many contenders opt for storing hydrogen in cylinders, which is unsafe and costly, compared to the alternative, generating hydrogen on demand.

Feedstock Development Issues

The efficient conversion of biomass into fuel still proves to be challenging in petrochemistry. First-generation biofuels (like vegetable oils) are more often used to produce food products, limiting their availability for fuel production. To address the shortage, a new generation of feedstocks is in development, derived from biomass waste or recycled carbon. However, these feedstocks require new processes, which can encounter technical and regulatory limitations.

Sustainability Concerns

Unmanaged biofuel production has a large environmental impact, as it can lead to negative consequences such as soil erosion, loss of biodiversity, water pollution, and deforestation. Implementing technologies that reduce carbon emissions, and promote the use of green or yellow hydrogen instead of traditional methods, is essential to mitigate these effects.

Digital Transformation

Increasing competition, particularly from emerging players, strengthens the need for continuous innovation to maintain a competitive edge in petrochemistry fields. Seamless automation between petrochemical reaction steps is difficult to achieve due to its costs, and the implementation of AI for lab data analysis requires time to be trained on internal processes.

Safe and Sustainable Reactions

To gain a competitive edge in the petrochemical industry, firms must stay up to date with technological advancements, particularly when it comes to chemical synthesis. Continuous flow chemistry provides a solution to most problems encountered during batch methods.

Accelerated Reaction Rates

Flow chemistry offers higher temperatures and pressures than traditional batch chemistry. Our reactors significantly shorten reaction times (from months to days), enabling rapid production of the desired compounds.

On-demand Hydrogen

ThalesNano instruments generate pure hydrogen on demand from water via electrolysis, eliminating the need for hydrogen cylinders or other storage methods.

Difficult Reactions Made Easy

Continuous flow technology provides a wide parameter scope and precise reaction parameter control, which simplifies difficult transformations, like the valorization of low-cost raw materials into useful chemicals.

Safe and Sustainable Technology

ThalesNano devices contribute to sustainability in many ways. Our reactors’ high temperatures and pressures permit the use of various environmentally friendly solvents and can activate less reactive materials with ease. Scientists can also start a synthetic transformation with bio-based materials as starting feedstocks, highlighting the versatility of flow reactors.

User-friendliness and Automation

Despite their ability to conduct complex syntheses, our flow reactors are easy to use, given their intuitive touchscreen interface. Moreover, scientists can connect these to third-party devices and automate reactions via our cutting-edge software.

Petrochemical Applications

- Hydrodenitrogenation: Removal of nitrogen from feedstocks and petrol/fuel-related mixtures.

- Hydrodesulfurization: Removal of sulfur from feedstocks and petrol/fuel-related mixtures.

- Dearomatization: Saturation of aromatic compounds in feedstocks.

- Hydrocracking: Hydrogenolytic cleavage of C-C bonds into smaller fragments.

- Isomerization: Rearrangement of carbon chains into branched compounds.

Choose Your Desired Output

H-Cube® Advance

- Temperature range: 0 - 150 °C

- Pressure range: Atm. to 100 bar

- Solvent and reagent flow rate range: 0.001-10 mL/min

- Internal hydrogen gas flow rate range: 1-70 NmL/min

- Built-in MFC for precise gas control

- Hydrogen purity: 99.9% (3.0)

- External gas inlet to connect additional gases

- External water reservoir

Phoenix Flow Reactor

- Temperature range: Amb. - 450 °C

- Pressure range: Atm. to 200 bar

- Solvent and reagent flow rate range: 0.001-30 mL/min

Connect it to the H-Genie®

- Hydrogen purity: 99.99% (4.0)

- Hydrogen gas flow rate range: 100 - 1000 NmL/min

- Water reservoir: 3000 mL

Instrument Fleets

- Modular, highly customizable, and scalable platform for a wide range of reaction types including multi-step synthesis

- Can consist of multiple flow reactors, hydrogen generators, gas and liquid inputs

- Seamless reaction parameter control and monitoring

- Generates hydrogen gas on-demand, eliminating the need for hydrogen cylinders

- Simultaneous parallel experiments can be controlled from a single user interface

- Third-party analytical devices or add-ons can be connected to the system

Scientific Studies

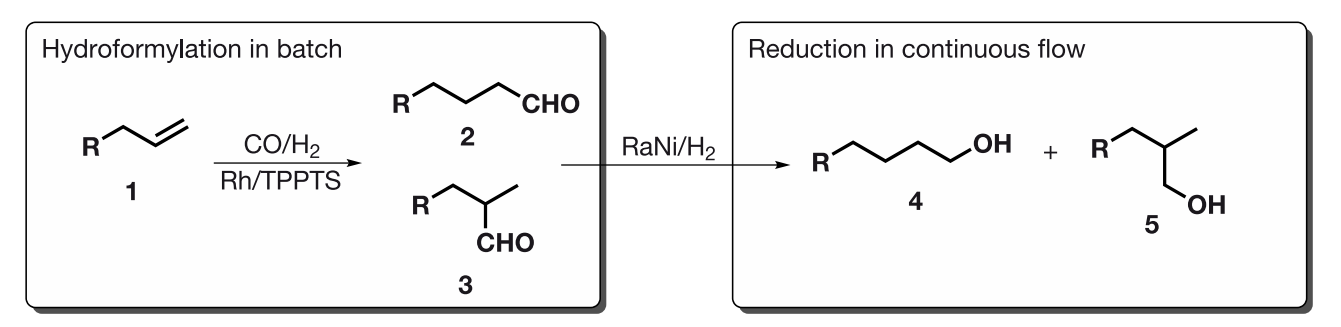

Hydroformylation of a Crude Mixture to Yield Valuable Fuel Additives

This application note showcases how ThalesNano’s H-Cube® Advance and Phoenix Flow Reactor were integrated by Dr. Andreas Vorholt’s group to advance the production of alcohol-based fuel additives from Fischer–Tropsch olefin mixtures. Using a continuous flow reductive hydroformylation process, the system safely generated hydrogen on-demand, enabling efficient conversion of crude hydroformylation products into valuable alcohols without intermediate purification.

By combining the modular flexibility of the Phoenix reactor with the safety and ease of the H-Cube®, the team achieved full hydrogenation at optimized conditions, producing high-quality bioderived alcohols suitable for diesel blends. The study highlights the scalability, robustness, and process efficiency of ThalesNano’s flow chemistry technology, offering a practical pathway toward sustainable fuels and reduced CO2 emissions.

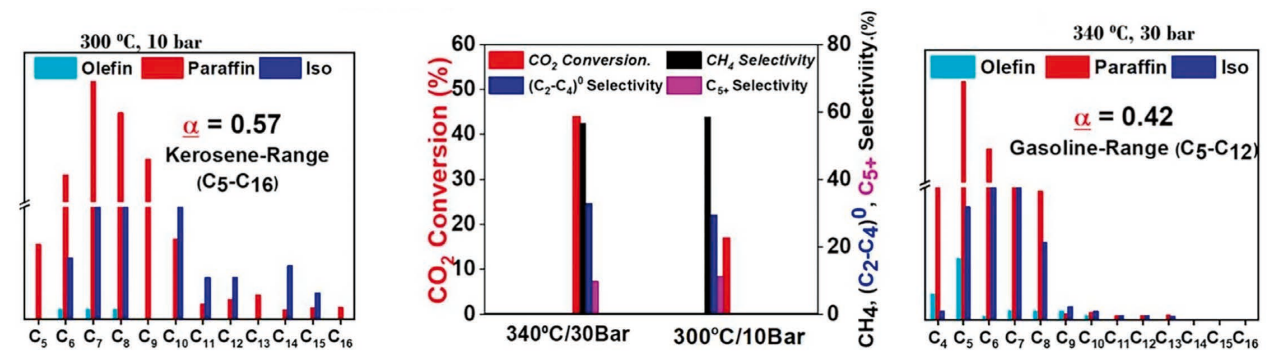

Carbon-Dioxide Conversion into Sustainable Fuels

This application note highlights how ThalesNano’s H-Genie® hydrogen generator enables safe and sustainable CO2 conversion into fuels using iron-based MOF catalysts in continuous flow. By generating high-purity hydrogen directly from water, the system eliminates the need for gas cylinders and allows precise, long-term testing under industrially relevant conditions. Researchers demonstrated the conversion of CO2 into paraffin hydrocarbons (C5–C16 range) with up to 44% efficiency at optimized temperatures and pressures, achieving excellent catalytic stability over 100+ hours.

Coupled with ThalesNano’s reactor technologies and automation software, this platform showcases a scalable and safe route to producing sustainable fuels while reducing greenhouse gas emissions—offering chemists and engineers a practical solution for carbon capture and utilization.

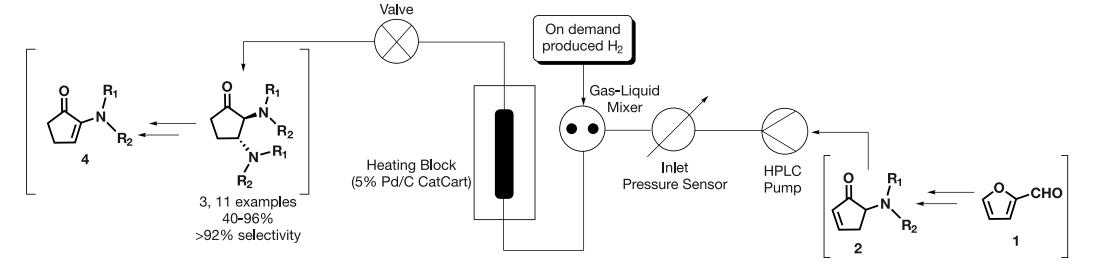

Valorization of Bio-based Raw Materials into Useful Petrochemicals and Fuels

This application note demonstrates how continuous flow technologies can turn low-cost, bio-based raw materials into valuable petrochemicals, fuels, and pharmaceutical intermediates. Prof. Carlos Afonso’s group demonstrated a multi-step flow synthesis using furfural to produce cyclopentenones—key intermediates for APIs—achieving high yields and selectivity while eliminating the need for excess reagents and purification steps. Meanwhile, Prof. Jeroen van Bokhoven’s team tackled a major fuel industry challenge: catalyst deactivation during methanol-to-hydrocarbon conversion.

By integrating multiple ThalesNano Gas Modules into their flow system, they showed how hydrogen can effectively regenerate zeolite catalysts, removing coke deposits and even converting them into useful hydrocarbons. Together, these studies showcase the power of ThalesNano’s modular flow reactors, hydrogen generators, and gas handling systems in enabling greener, safer, and more scalable processes for both the fuel and pharmaceutical industries.

Hydroformylation of Renewable Olefin Cuts for Drop-In Diesel Fuels

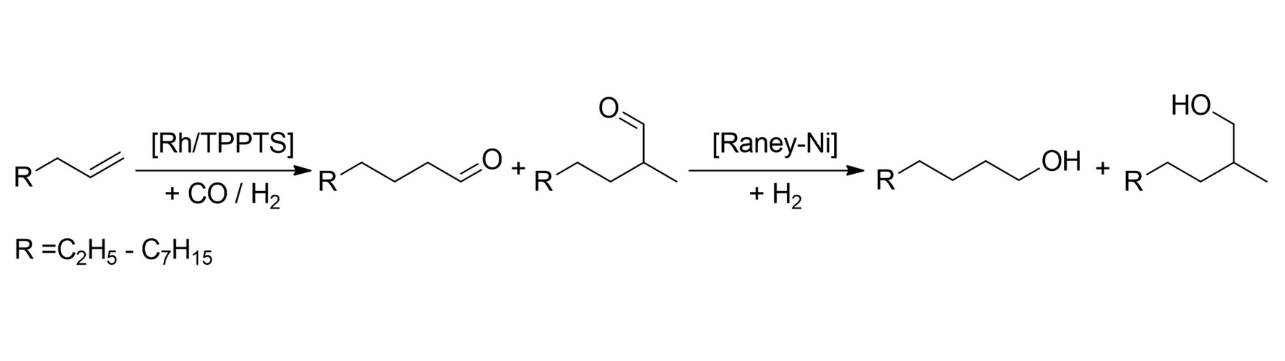

A ChemSusChem study by Püschel, Störtte, Topphoff, Vorholt, and Leitner demonstrates a green and scalable route for producing alcohol-based diesel additives from renewable Fischer–Tropsch olefin cuts (C5–C10) using reductive hydroformylation. The researchers combined a biphasic rhodium/TPPTS catalyst system with ThalesNano’s H-Cube® and Phoenix Flow Reactor, enabling continuous-flow hydroformylation and hydrogenation under safe, controlled conditions.

Their process achieved high turnover numbers (up to 68,419), low rhodium leaching, and stable operation for more than 50 hours. The final hydrogenation step with a Raney nickel catalyst converted the aldehyde-rich intermediates into alcohols, yielding drop-in biofuels with favorable combustion properties. This work provides a practical and robust pathway for CO₂-neutral fuels, supporting the REDIFUEL project’s mission toward sustainable mobility.

More Knowledge

FAQ

There is a wide variety of heterogeneous hydrogenations that have petrochemical applications: saturation of olefines and aromatics, desulfurization and denitrification, and hydrocracking.

Our continuous flow reactors are designed to be able to perform heterogeneously catalysed hydrogenations using in-situ generated hydrogen, which eliminates the need for hydrogen storage and complies with green and sustainable chemistry.

Our systems can be used for research in carbon capture and the reduction of CO2 emissions, as well as waste valorization and the synthesis of sustainable fuels and additives.

In our flow systems, mixing and heat transfer are significantly improved over batch protocols. Many safety features, including blockage and leakage detection, hydrogen sensors, one-way check valves and safety relief valves are also incorporated into our systems allowing for an inherently safe design.

Do you have more questions?

Reach out to us at any time and experience fast and efficient support tailored to your specific needs.