Pharmaceutical Industry

Safe and Efficient Drug Discovery in Flow

Pharmaceuticals - ThalesNano

Overview

The pharmaceutical industry works to improve patient outcomes and public health worldwide. From small biotechnology firms to global corporations, it develops medicines that prevent, treat, or manage diseases. Innovation drives companies to invest heavily in R&D, navigating lengthy trials and strict regulations to ensure safety and efficacy. Shaped by science, healthcare needs, patent laws, and competition, the industry also faces challenges such as high costs, pricing pressures, and global health disparities.

Challenges in Drug Discovery

Companies operating within the pharmaceutical and biotechnology industry face multiple difficulties, including complex regulations and high R&D costs. Drug discovery processes require significant time and cost, ensuring the accessibility and affordability of medications remains a constant challenge.

Regulatory Compliance

Pharmaceutical companies must navigate complex and evolving regulations like the FDA, WHO, and EMA. Staying compliant with regulatory requirements like clinical trial transparency rules and quality control requires good governance and significant capital spend. Failure to comply with these regulations may lead to penalties and reputational damage, making the regulatory landscape time-consuming and costly.

R&D Costs and Efficiency

The pressure to innovate and launch new therapies is constant within the industry, however, drug development is a lengthy and expensive process. Minimizing costs and maximizing efficiency are crucial for sustainable growth.

Synthetic Difficulties

Complex chemical structures often require lengthy synthetic pathways which could be low-yielding and tedious to develop.

Antibiotic Resistance

Increasing antibiotic resistance poses a significant threat to global health, therefore, developing new antibiotics and implementing strategies to combat resistance is critical.

Digital Transformation

Embracing digital technologies can improve R&D processes, clinical trials, and data management. However, integrating new technologies into existing infrastructure can be challenging.

Reactions made Safe, Easy, and Efficient

To improve the efficiency of pharmaceutical and biotechnology R&D processes, continuous flow technologies can be implemented, significantly decreasing reaction times and improving safety.

Adherence to Regulations

Flow chemistry systems are inherently safely designed and easy-to-operate, allowing the user to seamlessly increase reaction reproducibility and productivity while avoiding many safety regulatory hurdles.

Cost-efficient R&D

With ThalesNano instruments, users can reduce a reaction’s experimental times from days to minutes, making it possible to attempt up to 25 parameter combinations in a single 8-hour shift.

Difficult Reactions Made Accessible

Exploiting the advantages of flow chemistry allows the user to convert difficult transformations, such as saturation of aromatic rings, into easily accessible synthetic tools.

Combatting Antibiotic Resistance

By reducing development time, synthesis of new compound libraries becomes much quicker, allowing for a faster clinical trial screening of drug candidates.

Ease of Use and Seamless Integrations

Flow reactors can be automated and used together with third party instruments, allowing for remote control, immediate in-line analysis, and digitalization of experimental data.

Choose Your Desired Output

H-Cube® Advance

- Temperature range: 0 - 150°C

- Pressure range: Atm. to 100 bar

- Solvent and reagent flow rate range: 0.001-10 mL/min

- Internal hydrogen gas flow rate range: 1-70 NmL/min

- Built-in MFC for precise gas control

- Hydrogen purity: 99.9% (3.0)

- External gas inlet to connect additional gases

- External water reservoir

Phoenix Flow Reactor

- Temperature range: Amb. - 450°C

- Pressure range: Atm. to 200 bar

- Solvent and reagent flow rate range: 0.001-30 mL/min

Connect it to the H-Genie®

- Hydrogen purity: 99.99% (4.0)

- Hydrogen gas flow rate range: 100 - 1000 NmL/min

- Water reservoir: 3000 mL

Instrument Fleets

- Modular, highly customizable, and scalable platform for a wide range of reaction types including multi-step synthesis

- Can consist of multiple flow reactors, hydrogen generators, gas and liquid inputs

- Seamless reaction parameter control and monitoring

- Generates hydrogen gas on-demand, eliminating the need for hydrogen cylinders

- Simultaneous parallel experiments can be controlled from a single user interface

- Third-party analytical devices or add-ons can be connected to the system

Pharmaceutical Applications

- Continuous Flow Hydrogenations: Nitro group, nitrile group, carbonyl group reductions, C=C and aromatic ring saturations.

- Cross couplings (Suzuki, Sonogashira, Heck)

- Reactions with other gases (CO, CO2, ethylene, etc.): Carbonylations, carboxylations, ethynylations.

- Deuterations: Generate D2 gas in situ, or use D2O directly for H-D exchange reactions for isotope labelling.

- Increase Reaction Speed via Safe Overheating: Use low boiling point solvents at high temperatures to accelerate your reaction.

Scientific Studies

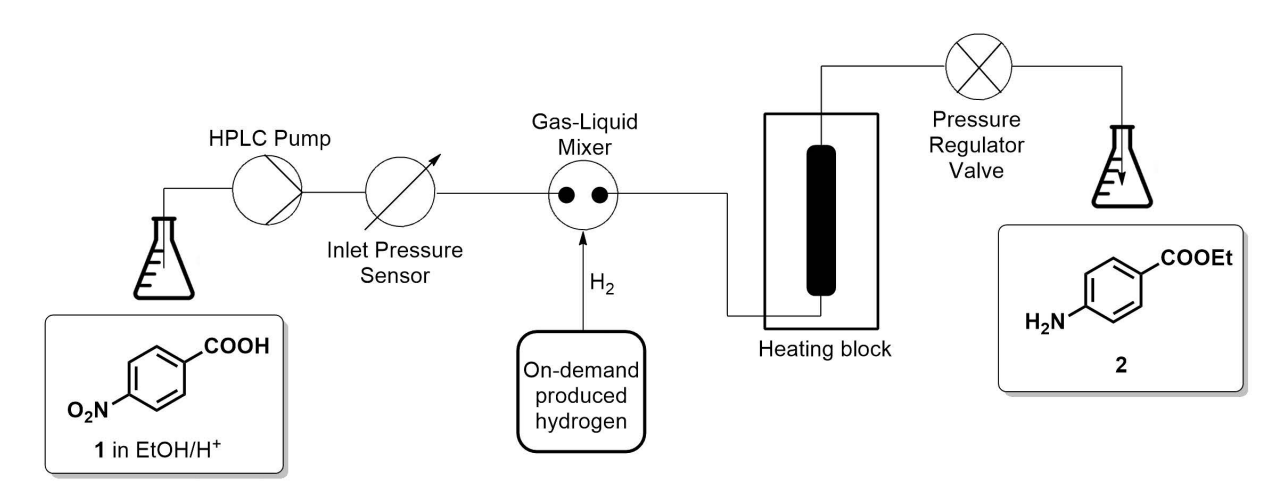

Simplifying API Research using Flow Technology

Our application note presents three case studies demonstrating the versatility of the ThalesNano H-Cube® Mini Plus continuous flow reactor in pharmaceutical research.

- A research team led by Kylie A. Vincent showcased the use of a hydrogenase-filled catalyst cartridge for the biocatalytic, H₂-driven reduction of riboflavin, offering a cost-effective cofactor recycling method.

- Using this approach, Rodrigo de Souza and colleagues developed a highly efficient single-step continuous flow synthesis of benzocaine, achieving >99% conversion and selectivity in just 12 seconds.

- In another study, Tamás Kálai’s group enabled a key hydrogenation step in the synthesis of a spin-labeled varenicline derivative, a potential theranostic agent.

The H-Cube® Mini Plus - designed for safety, precision, and ease of use - is a powerful tool for streamlining API synthesis, biocatalysis, and complex drug development on the laboratory scale.

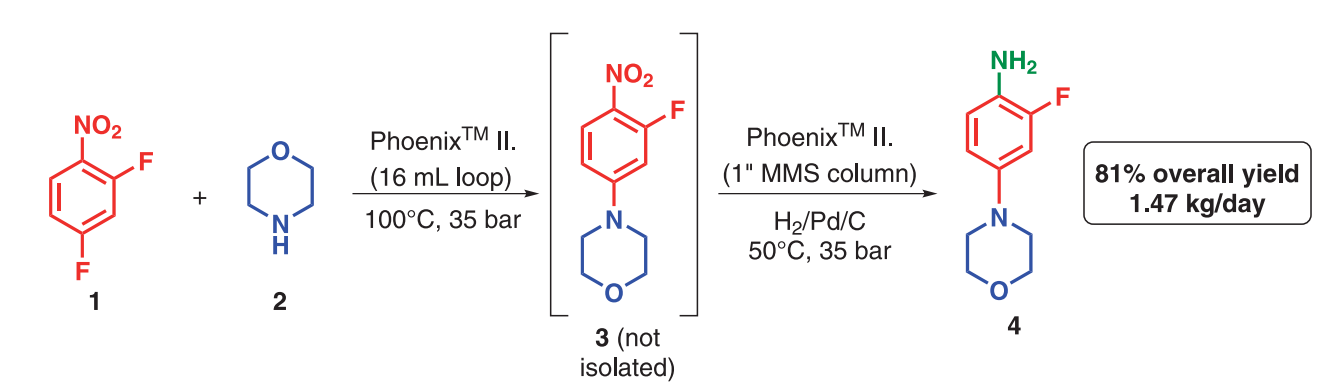

Linezolid analogue intermediate synthesis via N-arylation and nitro group reduction

Our review details the kilogram-scale continuous flow synthesis of a key Linezolid analogue intermediate using the ThalesNano Phoenix Flow Reactor combined with the H-Genie® hydrogen generator. A tandem two-step sequence was integrated: the N-arylation of morpholine with 2,4-difluoronitrobenzene, followed by catalytic nitro group reduction. Optimizing temperature, pressure, solvent, and flow rates yielded 81% product with 1.47 kg/day production capacity and excellent selectivity.

The Phoenix Flow Reactor’s high-pressure, high-temperature capabilities and the H-Genie®’s on-demand hydrogen generation ensured both safety and efficiency, while the compact setup allowed the entire scale-up process to be conducted within a standard fume hood. This study highlights the reactor’s ability to deliver industrially relevant quantities of complex pharmaceutical intermediates with precision, reproducibility, and safety.

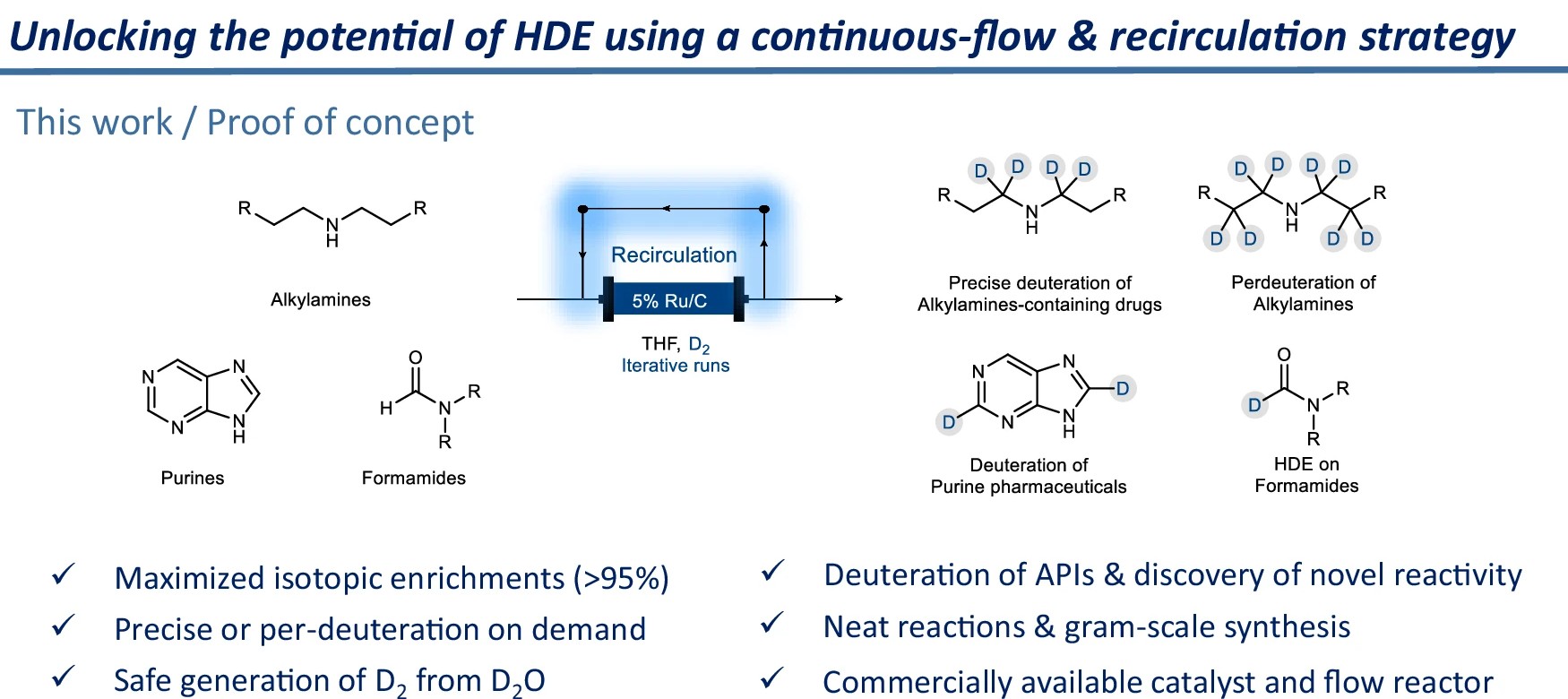

Hydrogen Deuterium Exchange via Continuous Flow Processes

In the study "Unlocking the potential of hydrogen deuterium exchange via an iterative continuous‑flow deuteration process" published in Nature Communications, the authors present a novel recirculation-based continuous‑flow method for high‑precision and high‑purity deuteration of organic compounds.

Utilizing the H‑Cube® Mini Plus and H‑Cube® Pro equipped with Ru/C catalysts, they achieved regioselective and perdeuterated labelling — often exceeding 95% isotopic purity — across a broad range of substrates, including amines, heterocycles, APIs, formamides, peptides, and polyamines. This approach combines speed, safety, scalability, and environmental friendliness, enabling gram‑scale production with minimal purification steps.

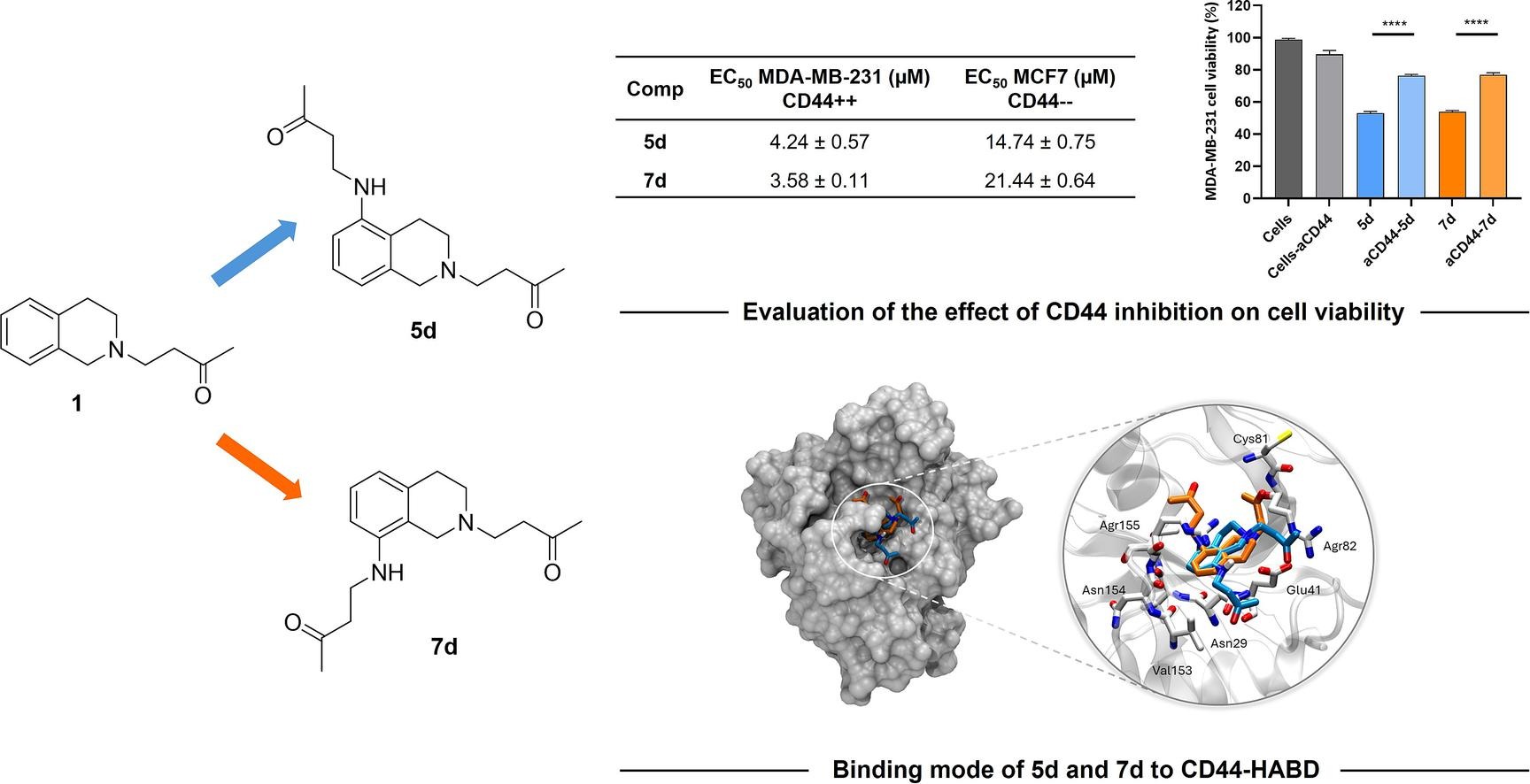

Synthesizing Potent CD44 Inhibitors with Promising Antitumor Activity

In their 2025 Bioorganic Chemistry publication, Chayah et al. describe the design, synthesis, and biological evaluation of new N-alkylketonetetrahydroisoquinoline derivatives as potent inhibitors of the hyaluronic acid (HA)–CD44 interaction in MDA-MB-231 breast cancer cells. The compounds were synthesized via catalytic hydrogenation in an H-Cube® reactor, enabling efficient and selective THIQ scaffold construction.

Structure–activity relationship studies showed that derivatives with a 3-butanone chain had the highest antiproliferative activity and strong HA-CD44 binding inhibition, confirmed by competitive binding assays and molecular dynamics simulations. The work expands the repertoire of targeted CD44 inhibitors, offering promising antitumor candidates and underscoring the H-Cube®’s role in streamlined, scalable synthesis.

More Knowledge

FAQ

Generally speaking, a few days are enough to learn the optimum conditions for a new/unknown reaction type. This will allow the user to attempt approximately 40-50 parameter combinations and perform TLC or GC/HPLC analysis on them, to determine if a quantitative conversion is achieved. Given an average sampling time of 15-20 minutes for each parameter, a 8-hour shift will allow the user to collect 30 samples daily.

First of all, we recommend flushing the system with pure solvent after each experiment. If the system is not actively in use, it should be started for 30 minutes every month to prevent damage to the electrolytic cells. Small consumables such as water purifier cartridges, membranes, sealing rings and check valves may be replaced by the user every 3-6 months. Larger parts, such as the cells themselves, are replaced by a ThalesNano employee when a service package is ordered by the customer (Recommended yearly: Preventive maintenance package).

In-situ generated hydrogen

Generating hydrogen gas on demand will allow the user to eliminate hydrogen cylinders and reduce the stored hydrogen to less than 1 mol.

Leakage and blockage detection

With built-in pressure monitoring, flow reactors will observe either excessively large or insufficient reaction pressures, and warn the user about a blocked or broken flow path.

Check valves and safety relief valves

A fully built flow reactor system contains multiple points where check valves are equipped (to prevent backwards flow), as well as safety relief valves that will automatically open and release excess pressures compared to a pre-defined value.

Yes, the H-Cube® Advance allows the user to conduct the gas into round bottom flasks or autoclaves. The H-Genie® hydrogen generators can also be used to fill balloons, autoclaves and other batch reactors, serving as a hydrogen source which is a safer alternative to cylinders.

Our catalyst cartridges (CatCart®s) can generally be regenerated after a reaction (unless working with starting materials of potent poisoning effect such as thiols/thiophenes). In an ideal case, one cartridge can convert up to ~10 grams of material.

Do you have more questions?

Reach out to us at any time and experience fast and efficient support tailored to your specific needs.