Phoenix-H-Genie® Platform

Hydrogenation System for Demanding Reactions

Hydrogenation with a Modular System

Designed to be used safely in any discovery, development, process, petrochemical or catalyst screening lab, the platform combines in-situ high pressure hydrogen generation with high temperature applications and precise gas data monitoring. Chemists and chemical engineers can now run hydrogen-based experiments with homogeneous or heterogeneous catalysts up to 450°C and 100 bar without the need for hydrogen cylinders or hydrogen storage.

Features of the Phoenix-H-Genie® Platform

Safe: The platform ensures safety by generating hydrogen on-demand through the electrolysis of water. It has the capability to produce up to 1 NL/min of hydrogen, making it safe to use in any laboratory setting. With this innovation, there’s no longer a need for hydrogen cylinders.

Versatile: The platform can accommodate temperatures of up to 450°C and pressures of up to 100 bar. It provides both homogeneous and heterogeneous reactor sets, catering to a wide range of experimental needs.

Scalable: To meet varying requirements, the platform offers a range of self-fillable cartridges or CatCarts. These allow for catalyst optimization and synthesis, enabling the synthesis of quantities ranging from milligrams to kilos.

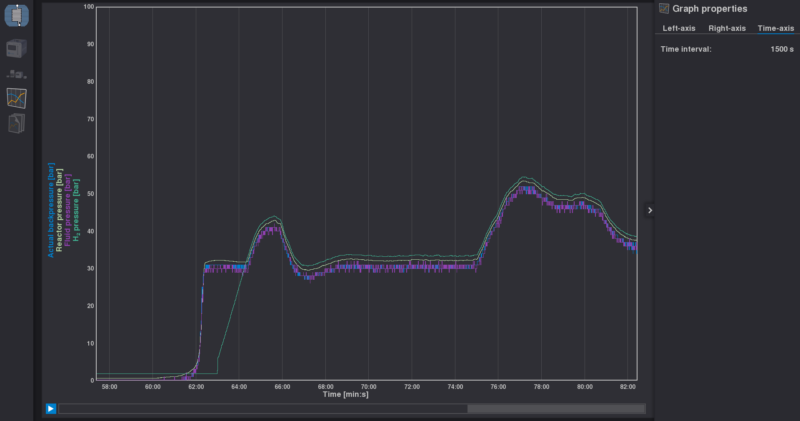

Precise: The platform is equipped with an in-built mass flow controller that ensures precise hydrogen pressure and flow rate monitoring. Users can easily export collected data for analysis and record-keeping.

Fast: With the ability to make quick changes to temperature, hydrogen pressure, and flow rate on the fly, the platform enables rapid optimization of experiments, saving valuable time.

Simple: The platform is designed with user-friendliness in mind, making it easy to set up and operate. Its intuitive interface ensures a smooth and hassle-free user experience.

Modular: The system set-up is highly customizable, allowing for tailored configurations based on specific user needs. This modular approach ensures flexibility and adaptability to various laboratory setups.

Remote Control and Monitoring

ThalesNano's Phoenix-H-Genie® Platform can be effortlessly controlled through the THS System Controller® and THS ReAction® Software. Therefore, a wide variety of custom configurations are possible and completely tailored to the researchers' needs.

Aside from standalone reactors and systems, THS ReAction® can operate consecutive, parallel, and failover fleets as well, making it suitable for laboratory optimization and scale-up processes.

THS System Controller® >>

Enables communication between all connected devices within the fleet. Its software counterpart, THS ReAction® Software, allows for precise operation of the entire fleet from a single screen.

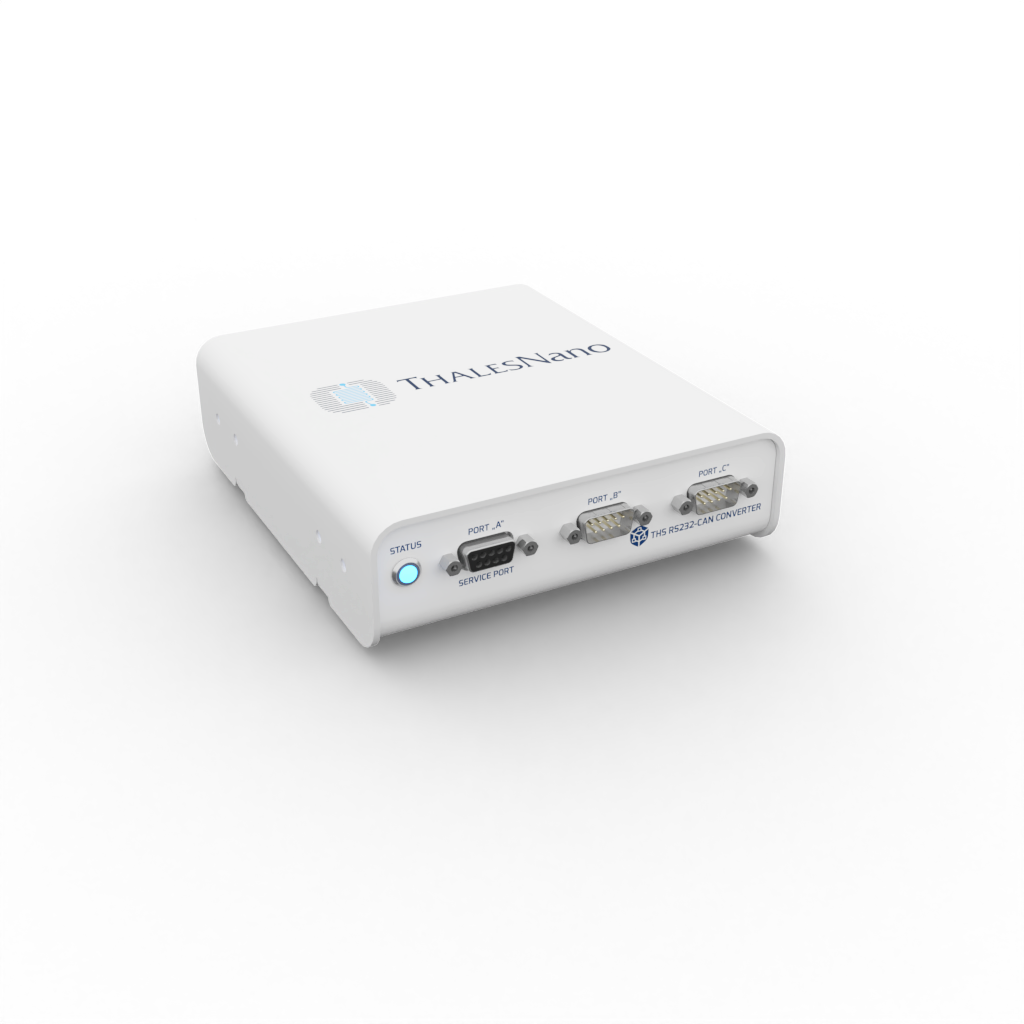

THS RS232-CAN Converter

Designed to connect external modules, such as HPLC pumps, mass flow controllers, and autosamplers to the fleet through the THS System Controller.

ThalesNano Modules of the Phoenix-H-Genie® Platform

Phoenix Flow Reactor >>

High-performance flow reactor with an extended parameter window (temperature up to 450°C, pressure up to 200 bar), enabling the synthesis of novel compounds.

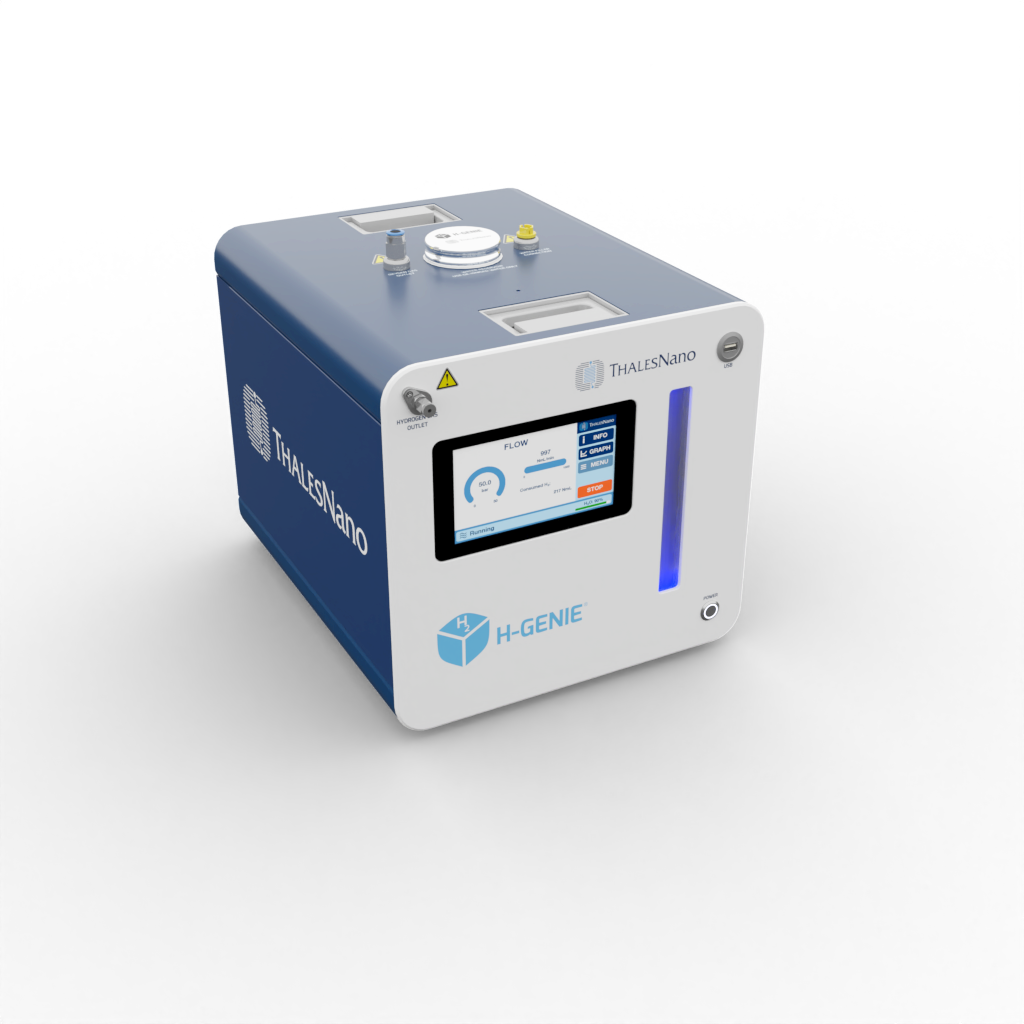

H-Genie® >>

On-demand, high pressure (up to 100 bar) hydrogen generator, producing 99.99% (4.0) pure hydrogen gas via water electrolysis, with flow rates up to 1NL/min.

H-Genie® Lite >>

On-demand, high pressure (up to 50 bar) hydrogen generator, producing 99.9% (3.0) pure hydrogen gas via water electrolysis.

Gas Module / Gas Module Plus >>

Designed for the precise dosing of 14 different gases at flow rates up to 1NL/min and up to 100 bar pressure.

Pressure Module 2 >>

New generation motorized back pressure regulator with a built-in pressure sensor. System pressure can be set up to 200 bar and pressure levels can be seamlessly monitored.

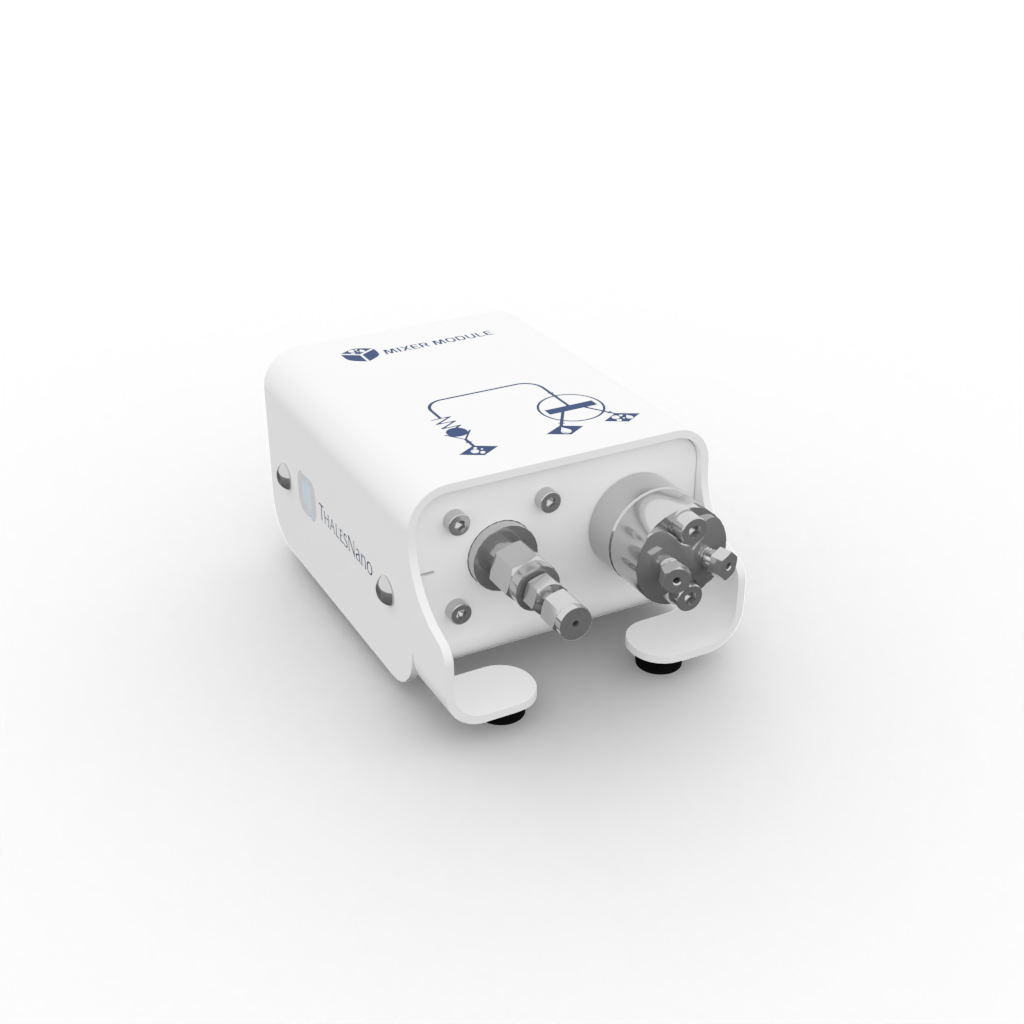

Mixer Module >>

High-performance static mixer for gas-liquid mixtures. Operates up to 200 bar and supports a wide variety of gases and liquids.

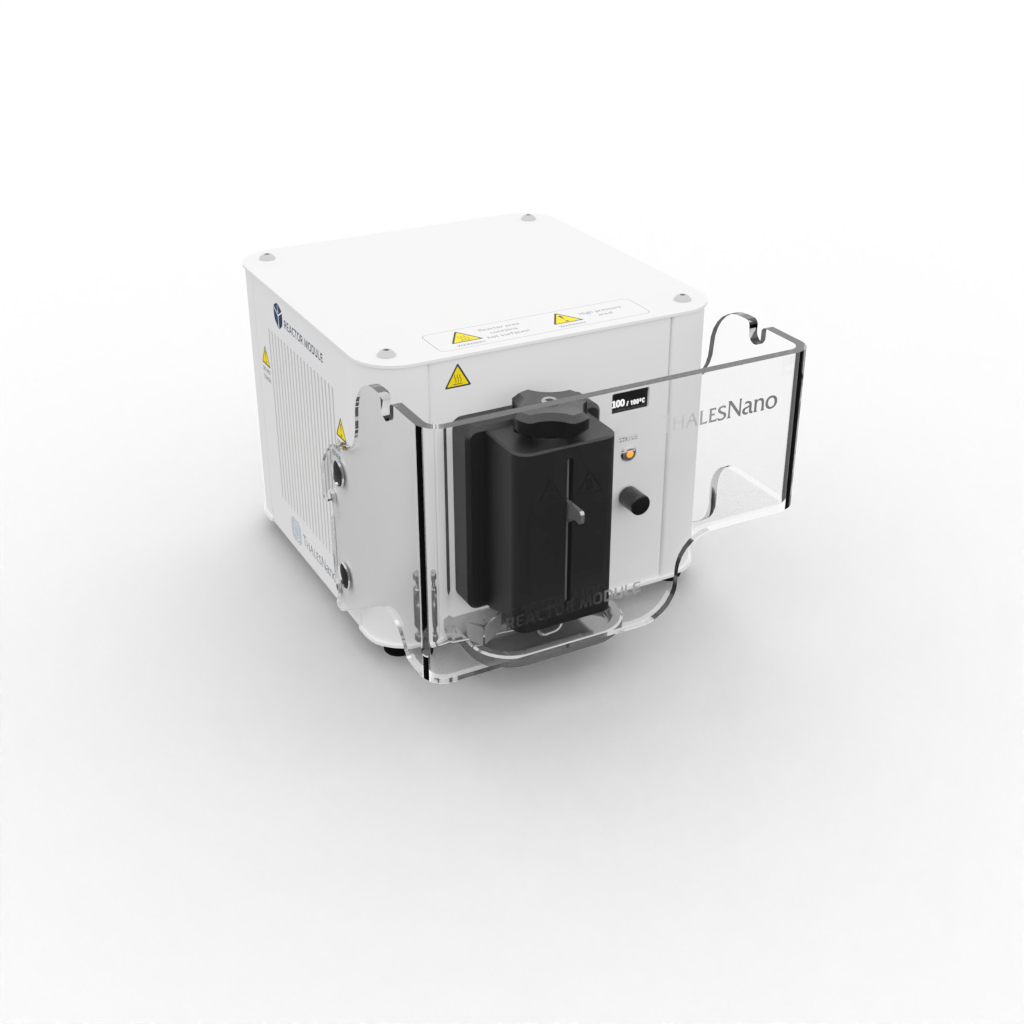

Reactor Module >>

High-temperature, high-pressure reactor unit for catalyst testing, catalyst screening, and multi-step reactions.

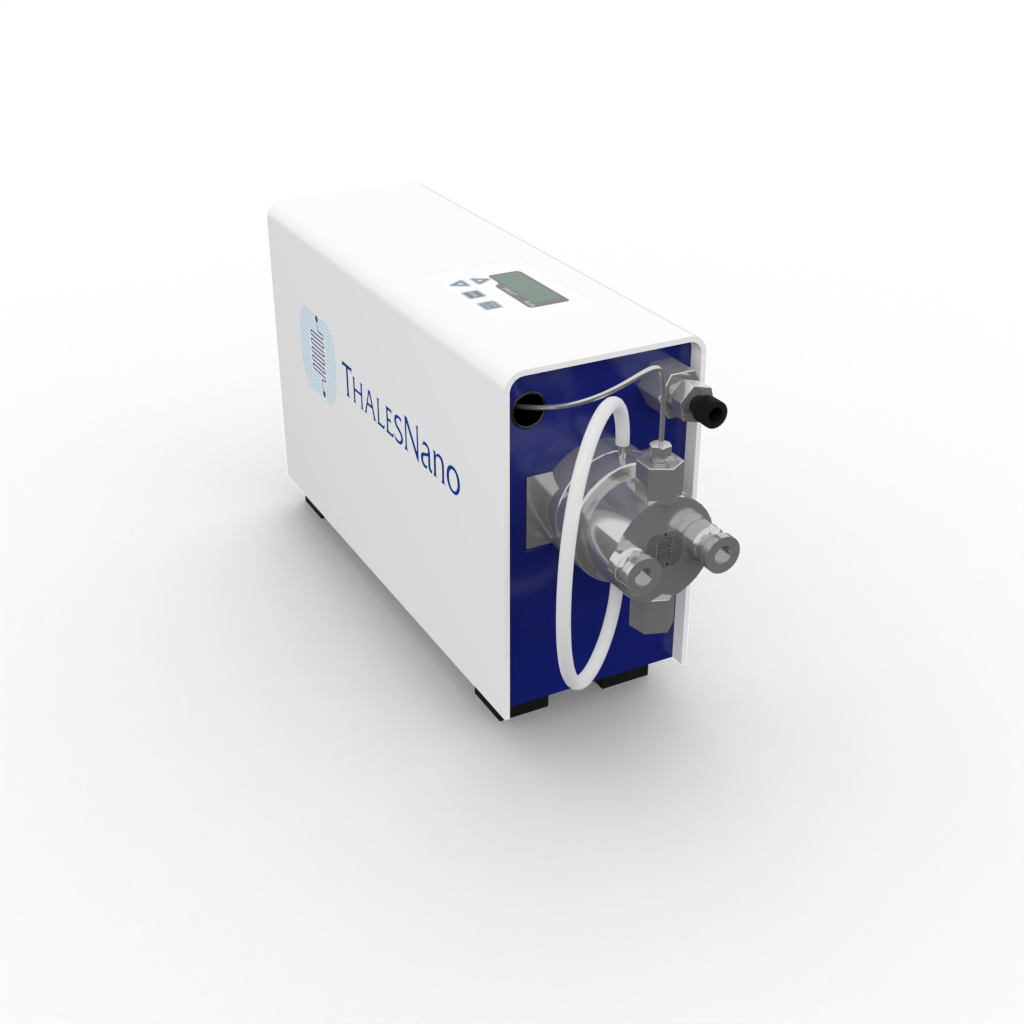

ThalesNano Micro HPLC pump

3 mL/min or 10 mL/min capacity pumps with built-in inlet pressure sensors, maintaining a constant flow within the system.

Supported External Modules of the Phoenix-H-Genie® Platform

Bronkhorst mass flow controller >>

Instrument with a gas database on board which provides real-time temperature and pressure compensation.

Knauer HPLC pump >>

10mL/min or 50mL/min capacity pumps with built-in inlet pressure sensors, maintaining a constant flow within the system.

Eldex Optos HPLC pump >>

Up to 80 mL/min capacity pumps with built-in inlet pressure sensors, maintaining a constant flow within the system.

Vici selector valve >>

High pressure selector valves are used for multi-column, multi-sample, or multi-trap operations.

Brooks AIM3300 Autosampler >>

Brooks’s module is designed to automate the continuous handling of liquid samples for the Instrument Fleets and the H-Cube® Advance.

Custom third-party modules

Other third-party devices can also be integrated into the system per user request. If you are interested in the system's compatibilities, reach out to us! Our experts are ready to discuss solutions customized to your application needs.

Available Heated Elements for the Phoenix-H-Genie® Platform

The Phoenix Flow Reactor is a powerful and versatile heating unit capable of reaching temperatures up to 450 °C. A big selection of ready-made reactor setups are available for both homogeneous and heterogeneous applications.

Packed bed reactors: Prefilled CatCarts (30 mm, 70 mm long CatCarts®) and MidiCarts® are available for safe and convenient catalyst testing. Researchers can use fillable metal-metal sealed cartridges with fittings from 1/8” OD to 1/2” OD with 125 mm and 250 mm lengths for a wide range of heterogeneous reactions. The reactor holder sets are made of four pieces in each case to fill up the internal volume of the Phoenix Flow Reactor's reaction zone.

Loops: 4, 8, or 16 or mL PTFE, stainless steel, and Hastelloy loops are available for homogeneous chemistry.

For custom-sized heated elements please contact us at askthechemist@thalesnano.com.

Applications

- SNAr reactions

- Boc-removal

- Claisen rearrangement

- C-alkylation

- N-alkylation

- Supercritical reactions

- Heterocycle synthesis

- Hydrogenation

- Oxidation

- Carbonylation

- Etc.

TESTIMONIALS

“Our laboratory specializes in the development, production and test fuels from various feedstock, and ThalesNano’s Phoenix II – H Genie II platform has been a versatile tool for process development, cutting cost in catalyst testing due to its g-kg scalability, and enables safe, in-situ hydrogenation. Aside from that, the system is easy to use and automate, it performs great in a wide variety of experiments.”

Do you have Questions?

Reach out to us at any time and experience fast and efficient support tailored to your specific needs.