Application Notes

Download, read, and share knowledge

At ThalesNano, we are dedicated to making knowledge accessible to all scientists. Our mission is to support education, research, and scientific collaborations, empowering scientists to share their experiences and find inspiration. Explore our Application Notes to discover how ThalesNano instruments can change your chemical research and help you achieve your chemistry goals.

Find the Application Notes sorted by instruments:

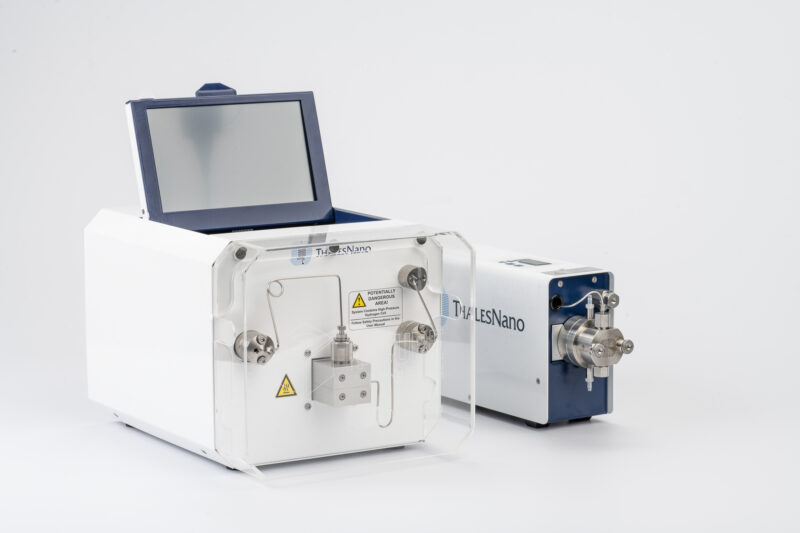

H-Cube

H-Genie

Phoenix Flow Reactor

Gas Module

PhotoCube

Automated Injection, Sampling and Real-Time Analysis in the Continuous Flow Hydrogenation of a Nitro Moiety on an Api Precursor

Medicinal chemistry application of chemoselective hydrogenation

Automated hydrogenation using the H-Cube continuous flow reactor

Catalyst screening and profiling with the H-Cube systems

Deuteration reactions using the H-Cube continuous flow reactor

Difficult hydrogenations – saturation of func. pyridines

Using an IR Spectometer from Mettler Toledo for In-Line Analysis of Continuous Flow Experiments

In this application note we feature the ReactIR™ 702L by Mettler Toledo coupled with ThalesNano’s Phoenix Flow Reactor system to highlight key advantages and showcase a study for all chemists looking for a convenient platform for high-pressure, high-temperature continuous flow reactions with in-situ H2 generation and in-line IR spectroscopic analysis.

Fast and continuous transfer hydrogenation of aromatic nitriles

Ethanol oxidation with heterogeneous catalysis in flow

Green and sustainable production of N-alkyl imidazoles

Ethanol oxidation with heterogeneous catalysis in flow

Sign up for our Newsletter for More Information

Do you have questions?

Reach out to us at any time and experience fast and efficient support tailored to your specific needs.