H-Cube® Advance

The Future of Safe and Efficient Hydrogenations

Improved chemical synthesis in continuous flow

The H-Cube® Advance is the next evolution in chemical synthesis, building on the proven success of our first H-Cube®, the R&D Top 100 winner unit, and the well-known H-Cube® Pro. Designed for modern laboratories, this push-button synthesis platform offers advanced features, a sleek and user-friendly interface, and enhanced functionality to simplify synthetic chemistry workflows in a safe manner.

Extended Application Capabilities

This compact, bench-top flow reactor, in addition to maintaining the basic functions of the original system, contains a number of improvements:

- Built-in MFC for the precise dosing of the produced hydrogen or the treatment of the external gases

- User-friendly interface, ergonomic design

- 3.0 (99.9%) produced hydrogen purity

- Compatibility with the THS ReAction software

Features of the H-Cube® Advance

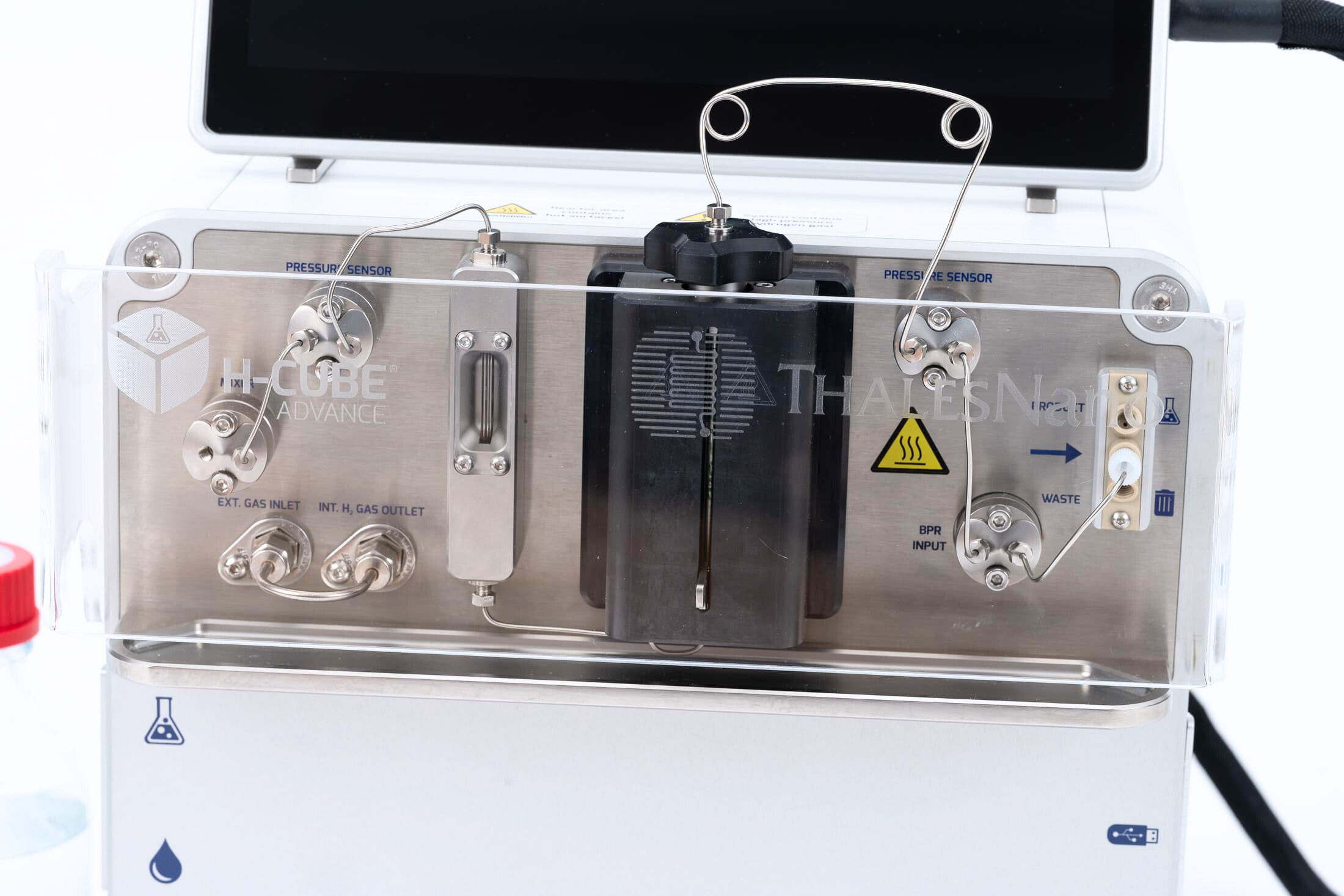

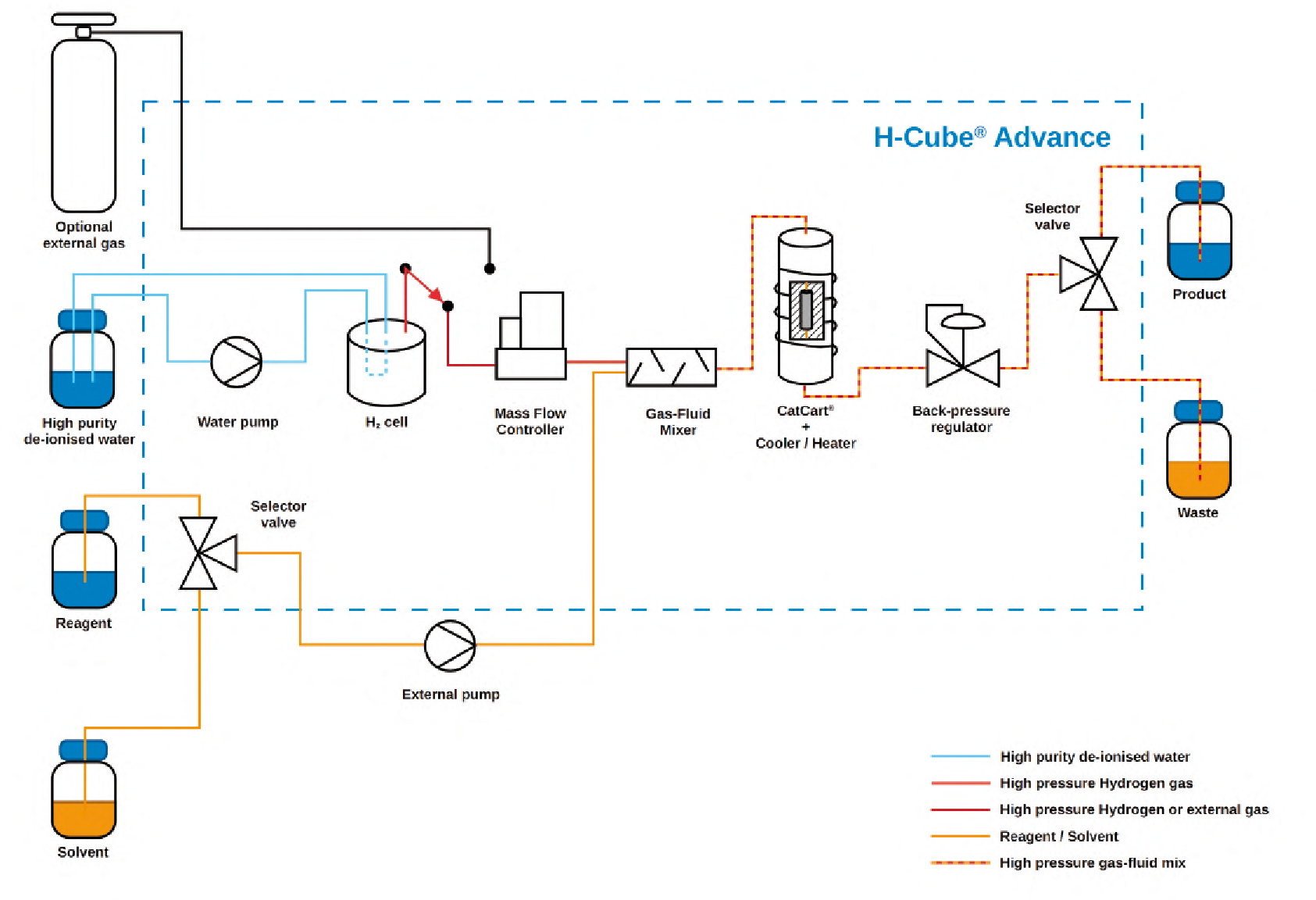

Built-in Mass Flow Controller (MFC): Ensures precise gas control, whether 99.9% pure in-situ hydrogen or other external gases for reproducible, scalable synthesis.

External Gas Inlet: Allows the introduction of additional gases through the built-in mass flow controller.

- Applicable gases: external hydrogen, oxygen, nitrogen, carbon monoxide, carbon dioxide, air, argon, ethylene, ethane, methane, helium, nitrous oxide, nitrogen monoxide.

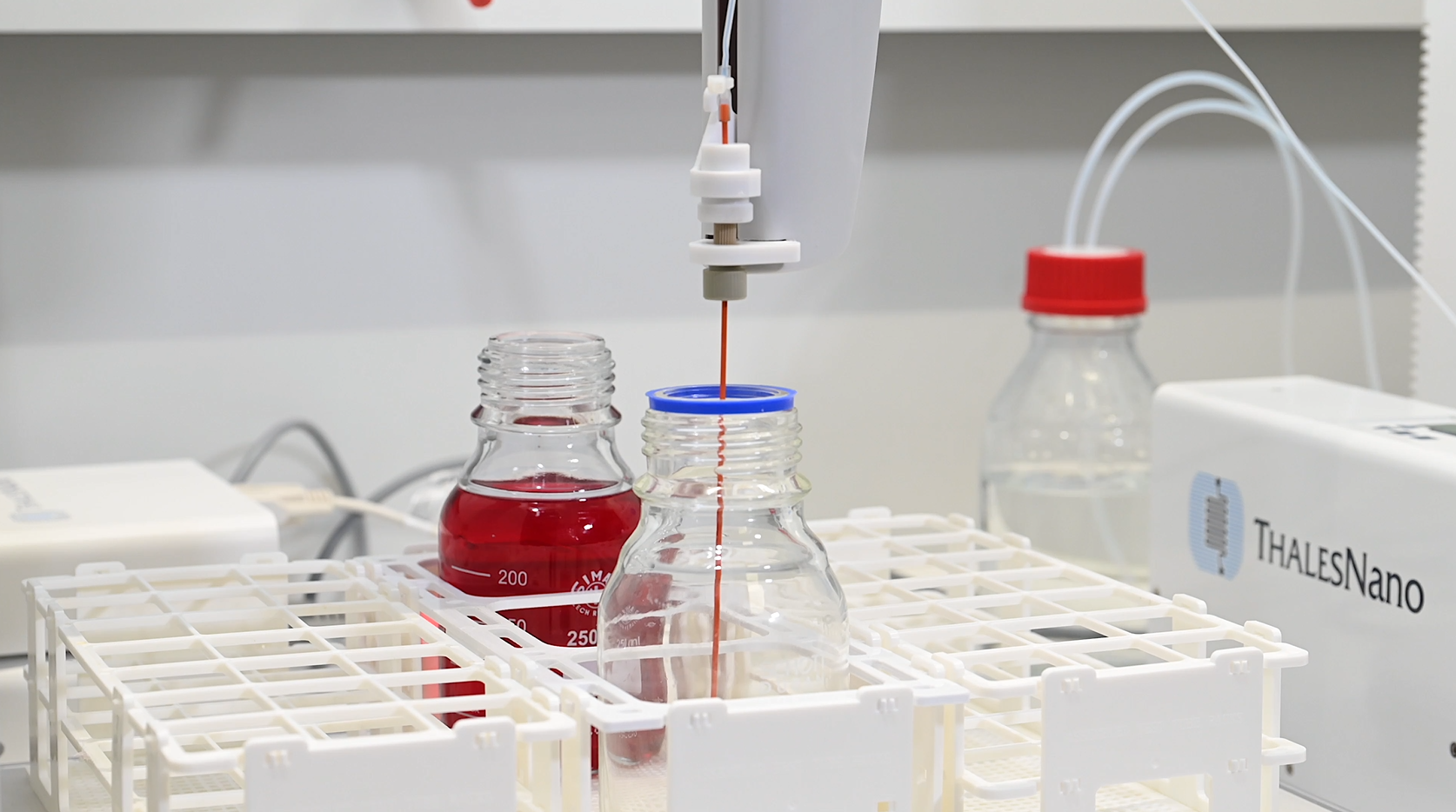

External Water Reservoir: Users can choose between flasks of variable sizes to fit specific needs, which are completely detachable from the device and easy to clean.

Next-Generation Water Electrolysis Cell: Efficient single-cell operation for consistent on-demand hydrogen production, which provides longer cell life and lower maintenance costs.

CatCart® Technology: Ensures safe and reliable catalyst handling by minimizing exposure to pyrophoric and toxic materials. The H-Cube® Advance is equipped with an easy to use CatCart® holder with ergonomic fitting nut knob and lift lever, moreover, the flow reactor is compatible with all ThalesNano CatCarts®.

Upgraded Internal and External Parts: The flow reactor's built-in system valve improves reaction efficiency and control, moreover, it comes with a built-in pressure sensor and mixer module, eliminating the need for further external add-ons - all it needs is a ThalesNano HPLC or Knauer pump to introduce the solvent and/or reactant to the system.

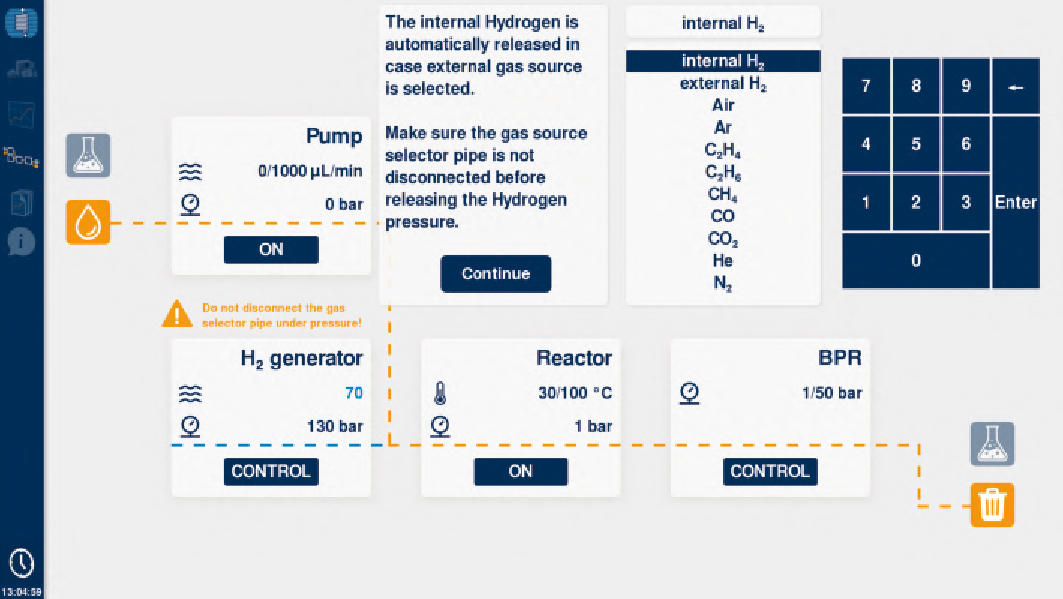

Touch Display with an User Friendly Interface: The reactor comes with an external 11.6" touch screen, and a seamlessly operable software equipped with automated and manual mode.

Automated Mode

Manual Mode

How does it work?

The H-Cube® Advance is mainly used for hydrogenation of many different starting material types, as well as catalyst screening. Additional supplied equipment, such as the HPLC pump, is used to introduce the reactant into the device, where the solution of reactant is mixed with the in-situ on-demand generated hydrogen.

The pre-heated mixture is then transferred to a disposable catalyst cartridge (CatCart®) which is preloaded with the required solid catalyst.

The mixture is then passed through the solid phase and then collected in a flask. In most reactions the only work-up required is the evaporation of the solvent.

Applications

Reactions with hydrogen gas:

- Triple bond full reduction

- Debenzylation

- Nitrile reduction

- Selective nitro reduction

- Selective triple to double bond reduction

- Selective double bond reduction

- Aldose reduction

- Aromatic heterocycle reduction

- Aromatic ring reduction

Other reactions:

- Deuteration

- Sonogashira coupling

- Suzuki coupling

Modules for the H-Cube® Advance

Reactor Module >>

High-temperature, high-pressure reactor unit for catalyst testing, catalyst screening, and multi-step reactions.

Phoenix Flow Reactor >>

High-performance flow reactor with an extended parameter window (temperature up to 450°C, pressure up to 200 bar), enabling the synthesis of novel compounds.

THS System Controller® >>

Enables communication between all connected devices within the fleet. Its software counterpart, THS ReAction® Software, allows for precise operation of the entire fleet from a single screen.

Brooks AIM3300 Autosampler >>

Brooks’s module is designed to automate the continuous handling of liquid samples for the Instrument Fleets and the H-Cube® Advance.

From Chemical Synthesis to Liquid Handling

Fully automated processes can be implemented when connecting the H-Cube® Advance with the Brooks AIM3300 Autosampler via the THS System Controller®, designed to automate the continuous sampling of liquid samples into an analyzer. Connecting the H-Cube® Advance to the Autosampler makes it ideal for performing optimization studies or catalyst screening.

System specifications of the H-Cube® Advance

| Technical Specifications | |

|---|---|

| Solvent and reagent flow rate range | 0.01-10 mL/min |

| Internal H2 gas flow rate range | 1-70 NmL/min |

| Gas types | Internal H2 or other external gases |

| Pressure range | Atmospheric to 100 bar |

| Reactor temperature range | 0 – 150 °C (32 – 302 °F) |

| Dimensions (H x W x D) | 330 x 320 x 330 mm (w/o display) |

| Display size | 11.6” (29.464 cm) |

| Weight | 18 kg |

| Mains range | 110 – 240 V AC, 50/60 Hz, 500 W |

Do you have questions?

Reach out to us at any time and experience fast and efficient support tailored to your specific needs.