Products & Services

Browse ThalesNano products and services

Our solutions

ThalesNano offers the widest available chemical space for synthesis. By expanding the parameter window of the traditional methods, our instruments can be used up to 450 °C, and pressures up to 200 bar. By this, reactions can be implemented in a safe and efficient manner, continuous flow reactions with gases become available, and high-temperature and high-pressure chemistry can be performed easily.

Hydrogen gas can be generatated on-demand, with the help of our streamlined hydrogen generators. By eliminating hydrogen cylinders completely, these instruments can make the use of hydrogen significantly safer for every laboratory.

Do you have questions?

Reach out to us at any time and experience fast and efficient support tailored to your specific needs.

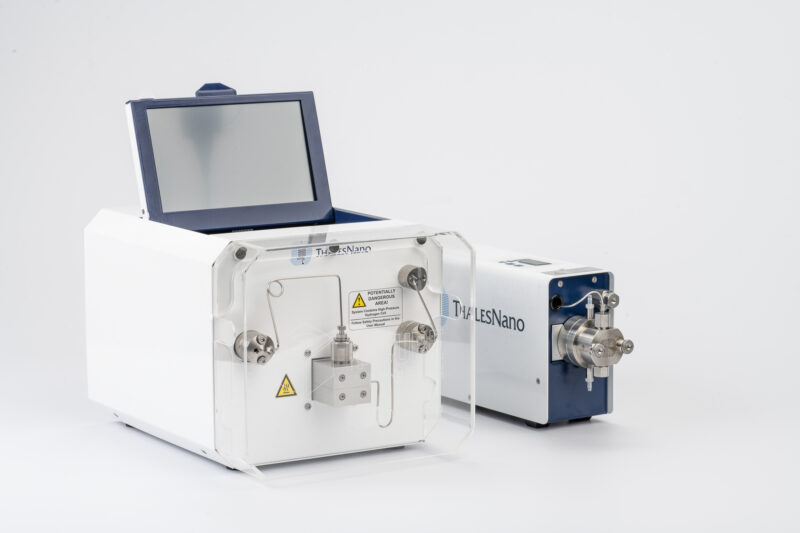

H-Cube continuous flow hydrogenation reactors

The H-Cube® system revolutionized laboratory hydrogenation when it was introduced in 2005, earning the prestigious R&D Top 100 award for ThalesNano in the same year. Since then, H-Cube® reactors have established a new industry standard by combining on-demand hydrogen generation and continuous flow technology within a single instrument. The latest additions to the H-Cube® family are the H-Cube® Mini Plus, the H-Cube® Pro, and the H-Cube® Advance.

The H-Cube Mini® Plus stands out for its user-friendly design, offering a modern and streamlined version of its original counterpart. With enhanced ease of use, this instrument ensures efficient small-scale laboratory hydrogenation.

On the other hand, the H-Cube® Advance is specially designed for complex hydrogenations and chemical synthesis with gases other than hydrogen. The built-in mass flow controller and the external gas inlet enables reactions with 14 different gases. Moreover, the flow reactor provides a wider temperature range, higher hydrogen production rate, and an user-friendlier interface than its predecessor, the H-Cube® Pro. The H-Cube® Advance flow reactor's Hastelloy version is made out of Hastelloy C, enabling reactions with corrosive materials, like acids and chlorines.

With their cutting-edge features and capabilities, the H-Cube® Mini Plus, the H-Cube® Pro, and the H-Cube® Advance continue the legacy of the H-Cube® system, pushing the boundaries of laboratory hydrogenation technology.

Learn more about our latest flow reactor

H-Cube® Advance

Advanced hydrogenation and chemical synthesis

H-Cube® Advance Hastelloy

Applications with corrosive materials

H-Cube® Pro

Flow reactor for advanced hydrogenation

H-Cube® Pro Hastelloy

Improved chemical resistance for hydrogenation

H-Cube® Mini Plus

Safe and easy hydrogenation for every lab

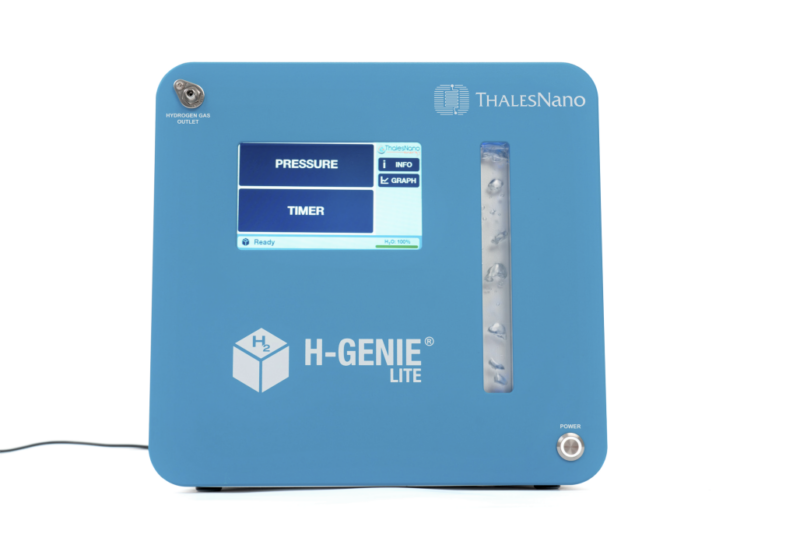

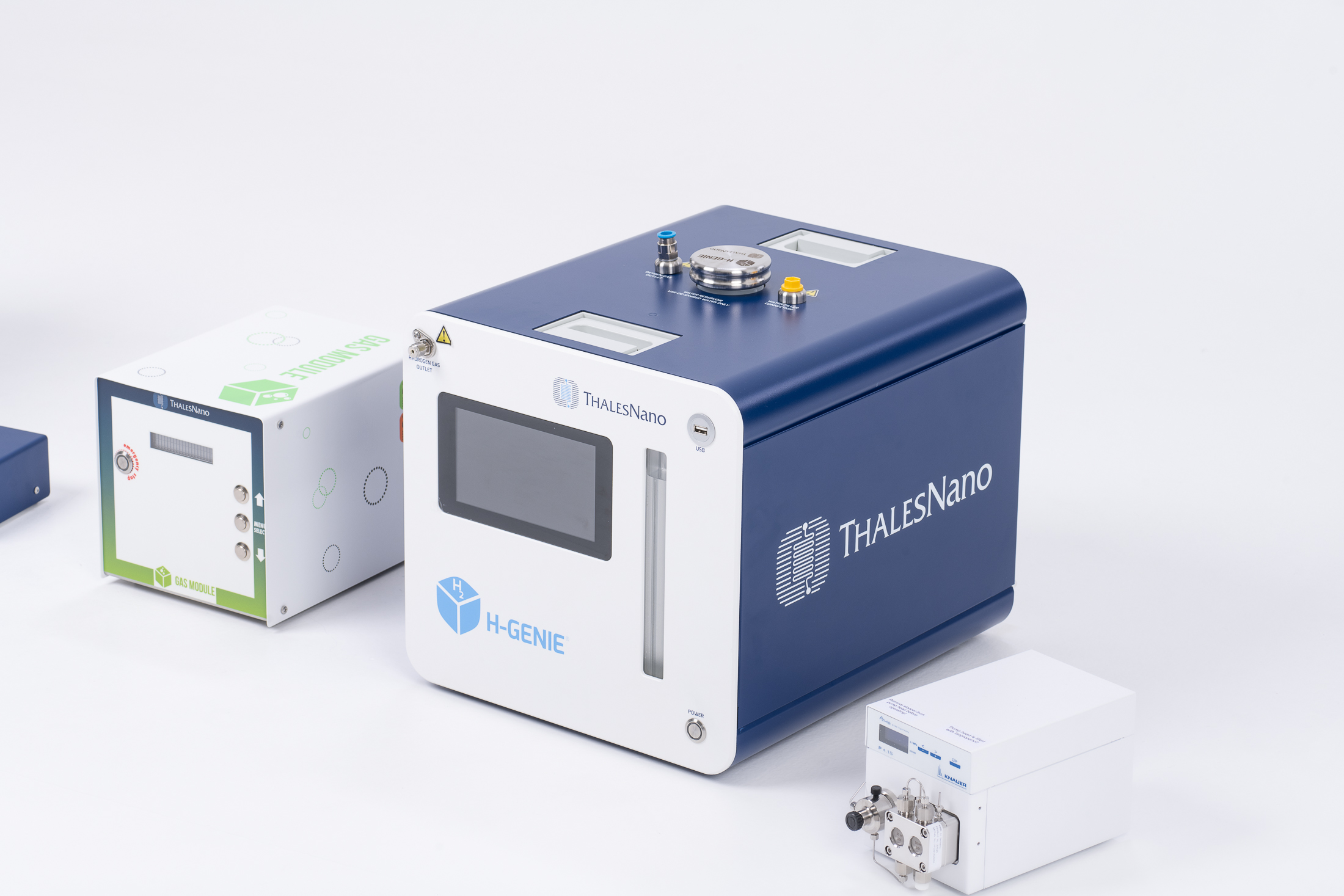

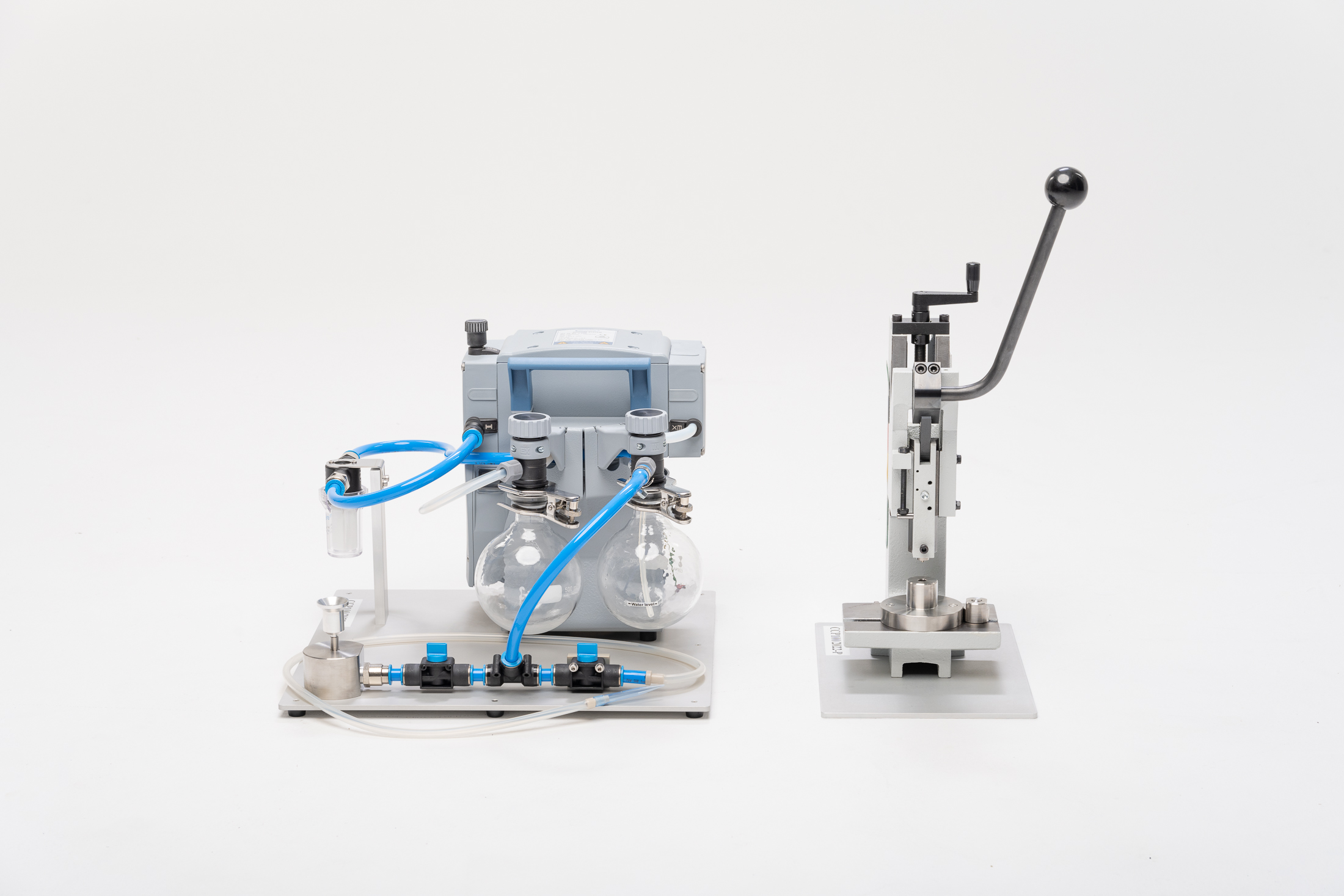

ThalesNano H-Genie® hydrogen generators

The H-Genie® systems are compact instruments specifically designed for on-demand hydrogen generation. Utilizing ThalesNano's patented technology, these instruments generate hydrogen gas through water electrolysis, eliminating the need for hydrogen cylinders. With the H-Genie® systems, you can conveniently produce hydrogen gas whenever it is required, making laboratory operations safer and more convenient.

By offering a more effective alternative to traditional hydrogen gas sources, the H-Genie® and H-Genie® Lite have become an invaluable addition to laboratories worldwide. Their compact design and efficient hydrogen generation make them the perfect solution for a wide range of applications.

H-Genie®

On-demand hydrogen generation for batch and flow chemistry

H-Genie® Lite

Replace your cylinders with high-pressure hydrogen generator

Phoenix flow systems

The Phoenix Flow systems open a new chemical parameter window for laboratory-scale synthesis. These advanced flow systems provide unparalleled capabilities, offering temperatures of up to 450 °C and pressures of up to 100/200 bar. Researchers can gain access to a wealth of new reactions and novel molecules that were previously unattainable using traditional laboratory equipment.

One of the key strengths of the ThalesNano Phoenix Flow systems lies in their exceptional flexibility. These systems can be tailored to your specific chemical needs through a range of additional modules for hydrogen generation, gas introduction, reaction monitoring, and automation, allowing you to customize the system to suit your unique requirements.

Phoenix Flow Reactor

Versatile and powerful flow reactor

Phoenix-H-Genie® Platform

Moduar hydrogenation platform

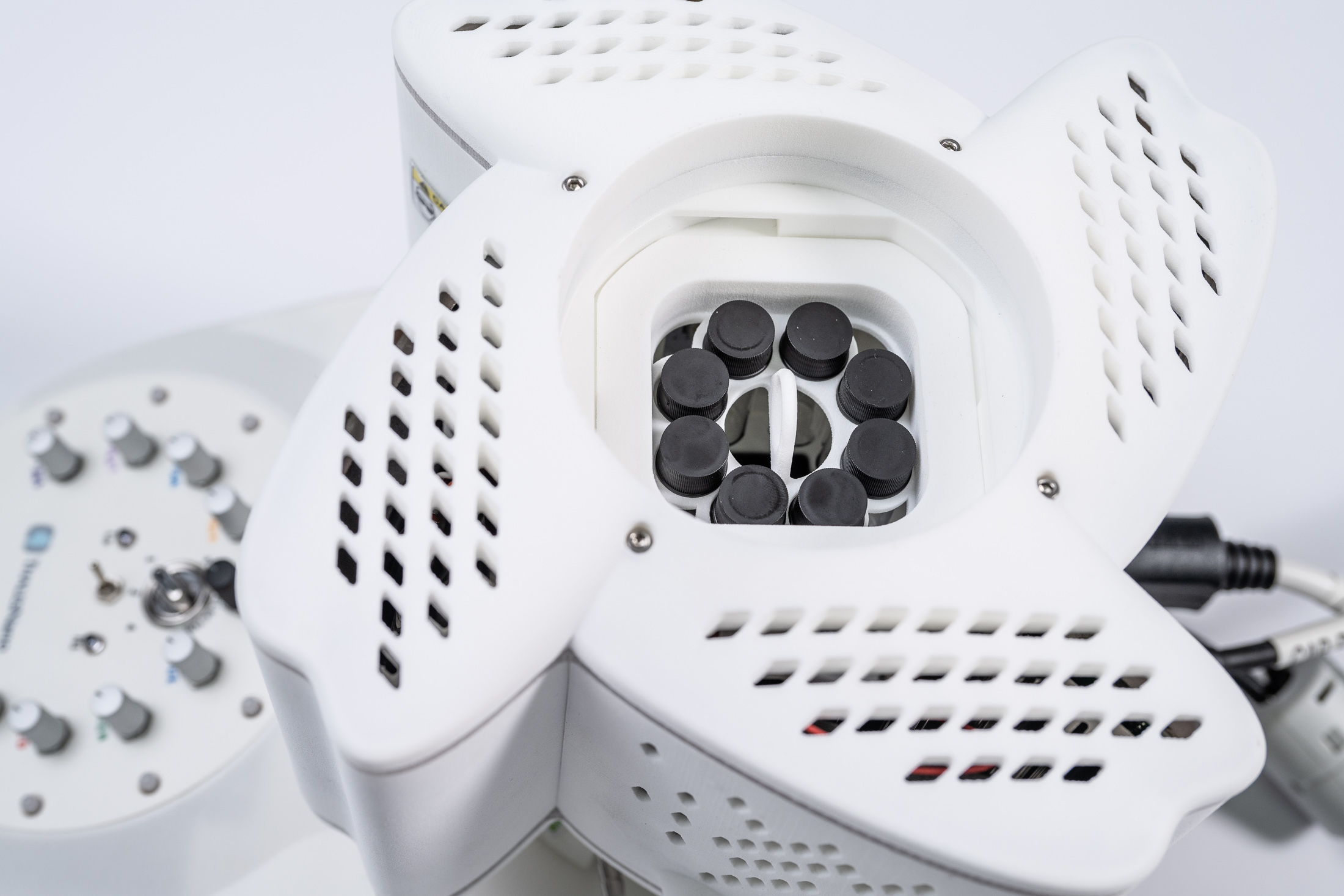

PhotoCube

The PhotoCube is the award-winning innovative instrument of ThalesNano that revolutionizes photochemical reactions in the laboratory. With its advanced design and cutting-edge features, the PhotoCube offers unprecedented control and precision in photochemistry experiments.

The PhotoCube boasts exceptional versatility, accommodating various types of batch and flow reactions, and providing precise control over parameters such as light intensity, wavelength, and exposure time.

PhotoCube

Batch and flow photochemical reactions

Gas Module

This module enables precise dosing of various gases, offering a seamless integration of gas handling capabilities into your workflow. It supports a wide range of gases, including hydrogen, nitrogen, oxygen, and more, allowing you to tailor the gas environment to meet your specific experimental requirements. The Gas Module seamlessly integrates with other ThalesNano instruments and modules (including the H-Cube Pro and the Phoenix flow systems), allowing for comprehensive control of your laboratory processes.

Gas Module

Reactions with gases made easy

CatCart® solutions from ThalesNano

CatCarts® play an important role in enhancing the safety and efficiency of heterogeneous catalysis when used with the H-Cube® or Phoenix flow systems of ThalesNano. These specially designed cartridges, available as pre-packed options or user-fillable variants, feature integrated filters that enable the smooth flow of gases and liquids while securely containing solid reagents. This unique configuration not only accelerates continuous flow synthesis but also ensures a safer and more convenient laboratory experience.

With our diverse CatCart® portfolio, you can select from a range of pre-packed cartridges tailored to specific catalytic applications. Alternatively, you have the flexibility to fill your own cartridges with the CatCart® Packer, customizing them to meet your unique requirements.