Phoenix-H-Genie Platform

Hydrogenation system for high-demanding reactions

Hydrogenation with a modular system

Designed to be used safely in any discovery, development, process, petrochemical or catalyst screening lab, the hydrogenation platform combines in-situ high pressure hydrogen generation from water with high temperature reactor capability and a precise gas data monitoring system. Chemists and chemical engineers can now run hydrogen-based experiments with homogeneous or heterogeneous catalysts up to 450°C and 100 bar without the need for hydrogen cylinders or hydrogen infrastructure.

Features of the Phoenix-H-Genie Platform

Safe: The platform ensures safety by generating hydrogen on-demand through the electrolysis of water. It has the capability to produce up to 1 NL/min of hydrogen, making it safe to use in any laboratory setting. With this innovation, there’s no longer a need for hydrogen cylinders.

Versatile: The platform offers exceptional versatility, accommodating temperatures of up to 450°C and pressures of up to 100 bar. It provides both homogeneous and heterogeneous reactor sets, catering to a wide range of experimental needs.

Scalable: To meet varying requirements, the platform offers a range of self-fillable cartridges or Catcarts. These allow for catalyst optimization and synthesis, enabling the synthesis of quantities ranging from milligrams to kilos.

Precise: The platform is equipped with an in-built mass flow controller that ensures precise monitoring of hydrogen pressure and flow rate data. All data collected can be easily exported for analysis and record-keeping.

Fast: With the ability to make quick changes to temperature, hydrogen pressure, and flow rate on the fly, the platform enables rapid optimization of experiments, saving valuable time.

Simple: The platform is designed with user-friendliness in mind, making it easy to set up and learn how to operate. Its intuitive interface ensures a smooth and hassle-free user experience.

Modular: The system set-up is highly customizable, allowing for tailored configurations based on the specific needs of customers. This modular approach ensures flexibility and adaptability to various laboratory setups.

Modules of the Phoenix-H-Genie Platfrom

H-Genie®: With the H-Genie hydrogen generator, you can use high purity hydrogen gas for your reactions. Hydrogen is generated on-demand from water at pressures up to 100 bar (14.5–1450 psi) and at flow rates up to 1 NL/min.

Gas Module: The Gas Module (max. 100 NmL/min gas flow rate) allows the introduction of gases, such as carbon monoxide, oxygen, syngas to the liquid flow. Gases can be used up to 100 bar pressure, widening the reactor’s chemistry capabilities significantly. It is also possible to use more than one Gas Module and mixers to introduce more than one gas at the same time.

Recommended gas regulators: N2 regulator - Linde C200/1A-200B; O2 regulator - Rhöna EN OX 03-10, H2 regulator - Linde fdr-200-100-380-h

Gas Module Plus: The Gas Module Plus is purpose-built for accommodating larger quantities of gases. It seamlessly integrates with ThalesNano reactor systems, such as the H-Cube Pro and the Phoenix Flow systems. This module guarantees precise and controlled gas dosing at flow rates of up to 1 NL/min, extending the gas flow range beyond that of the original Gas Module.

Mixer Module: By dispersing gases into fine bubbles, the Mixer Module significantly enhances the effectivity of gas-liquid phase mixing, while also expanding surface area and increasing reaction yields.

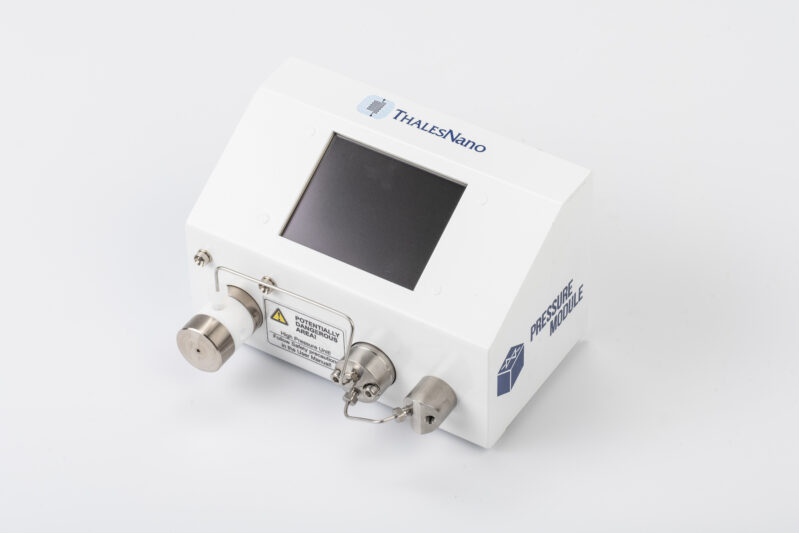

Pressure Module: The Pressure Module generates pressure in the reaction chamber. The module contains a system valve, a pressure sensor and a 3-way valve to set the outlet (to waste or to product collection). The maximum pressure is 100/200 bar (depending on other modules used with the Phoenix Flow Reactor).

HPLC pumps: HPLC pumps are 10 mL/min or 50 mL/min capacity units with built-in pressure sensors (inlet pressure sensors). It is recommended to have extra HPLC pumps if multiple inlets are needed for the choosen application.

THS System Controller® and THS ReAction® Software: The THS System Controller® module and the THS ReAction® software provide comprehensive control over every individual module within the system. With their help, users can monitor the parameters of each module, enabling seamless integration and optimal performance of the Phoenix Flow System.

Available heated elements for the Phoenix-H-Genie Platform

The Phoenix Flow Reactor is a powerful and versatile heating unit capable of reaching temperatures up to 450 °C. A big selection of ready-made reactor setups are available for both homogeneous and heterogeneous applications.

Packed bed reactors: Prefilled CatCarts (30 mm, 70 mm long CatCarts®) and MidiCarts are available for safe and convenient catalyst testing. User-fillable metal-metal sealed cartridges with fittings from 1/8” OD to 1/2” OD with 125 mm and 250 mm lengths can be used for a wide range of heterogeneous reactions. The reactor holder sets are made of four pieces in each case; they are required to fill up the internal volume of the Phoenix Flow Reactor's reaction zone.

Loops: 4, 8, or 16 or mL PTFE, stainless steel, and Hastelloy loops are available for homogeneous chemistry.

For custom-sized heated elements please contact us at askthechemist@thalesnano.com.

Applications

SNAr reactions, Boc-removal, Claisen rearrangement, C-alkylation, N-alkylation, supercritical reactions, heterocycle synthesis, hydrogenation, oxidation, carbonylation, etc.

Do you have questions?

Reach out to us at any time and experience fast and efficient support tailored to your specific needs.