Hydrogenation

On-demand hydrogen generation to eliminate hydrogen cylinders

Hydrogenation reactions

Catalytic hydrogenation stands as a cornerstone in the realm of modern chemical industry, offering significant transformations with diverse applications. Heterogeneously catalyzed hydrogenations are widely employed for a range of crucial conversions, including:

- Reduction of double or triple bonds

- Nitro-group reduction

- Debenzylation reactions

- Heterocycle saturations

- Dehalogenation reactions

- Desulphurization reactions

- Asymmetric hydrogenations

Traditionally, hydrogenations have been performed using batch technology, yet this approach presents several disadvantages:

- The use of hydrogen cylinders poses a safety hazard.

- The catalysts themselves can be pyrophoric, making their addition or filtration a hazardous process.

- The degassing of solvents and purging of reactors with inert gases add unnecessary complexity to the reactions.

- Poor mixing of hydrogen with solvents and catalysts results in lengthy reaction times.

These combined drawbacks have prompted chemists to seek alternatives, avoiding the otherwise valuable transformation. At ThalesNano, we have developed the H-Cube reactors and the H-Genie hydrogen generators to introduce safe and convenient hydrogenation practices in the laboratory.

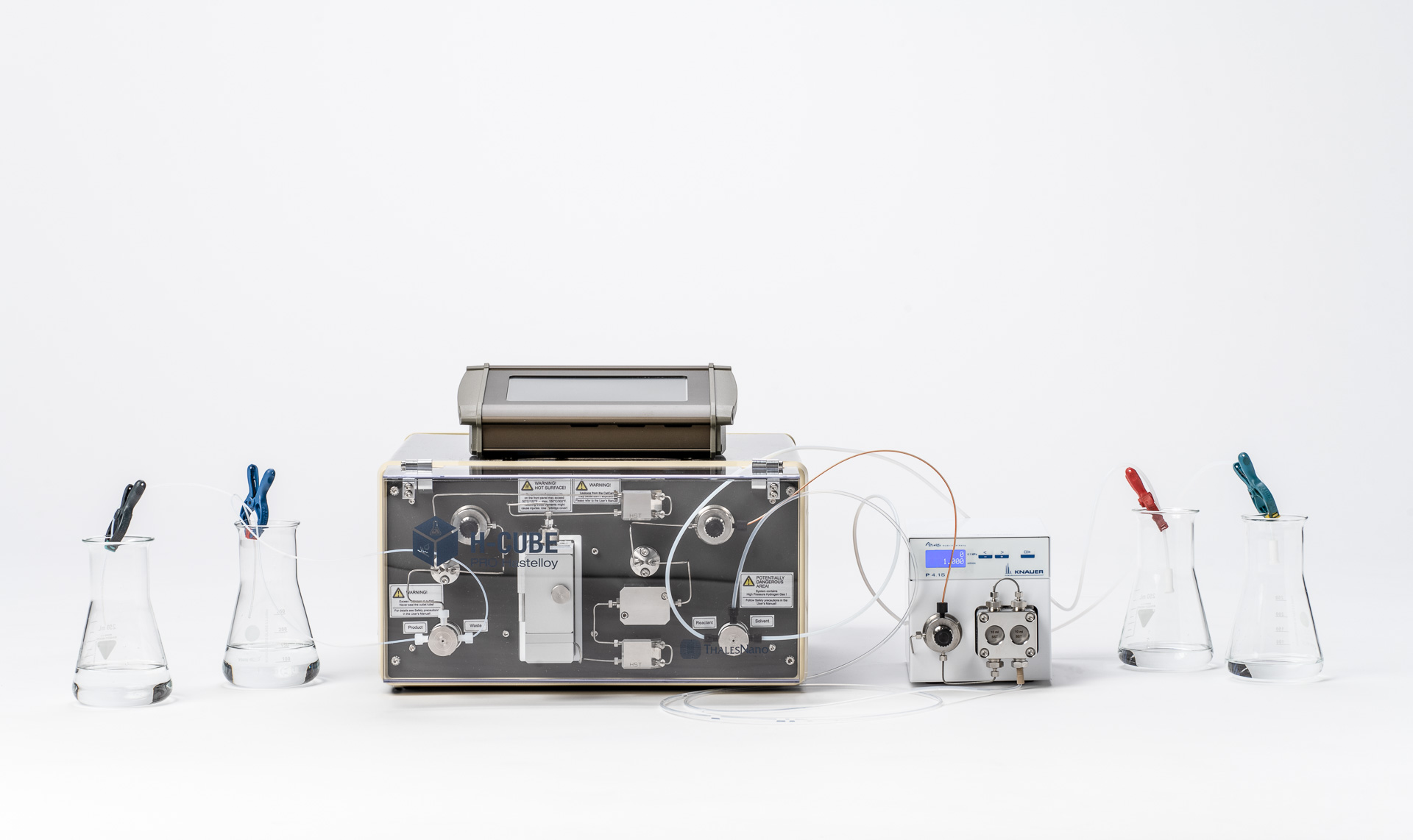

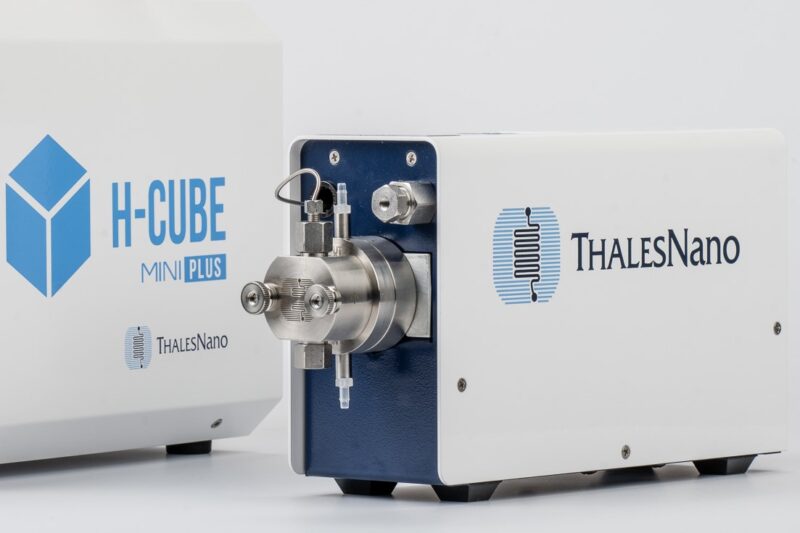

H-Cube series flow reactors

The first H-Cube system was a revolutionary concept in the early 2000s, allowing the generation and use of high-pressure hydrogen gas in continuous flow (up 100 bar pressure ad 100 °C temperature). Since then, it has been instrumental in transforming hydrogenation laboratory practices and scientific research. With over 700 publications showcasing the impact of the H-Cube series reactors, they have proven to be essential in advancing the field of chemistry.

Explore our extensive collection of articles and application notes to witness the diverse range of applications where H-Cube systems have excelled over the past two decades. From state-of-the-art research to practical laboratory workflows, discover how the H-Cube reactors have revolutionized hydrogenation reactions and empowered scientists worldwide.

On-demand hydrogen generation

Introducing on-demand hydrogen generation—an innovative solution that addresses the limitations of traditional methods and eliminates the need for hydrogen cylinders entirely. Our H-Cube and H-Genie systems employ patented technologies that enable the generation of high-pressure hydrogen via water electrolysis. This groundbreaking approach not only simplifies laboratory processes but also enhances safety, meeting stringent laboratory regulations as there is no longer a requirement to store hydrogen gas.

The generated hydrogen gas can be readily utilized for a wide range of chemical transformations, catering to both traditional batch reactors and flow chemistry equipment. This revolutionary capability equips synthetic chemists with an invaluable tool, setting a new standard for hydrogenations on a laboratory scale.

Learn more about the convenience, safety, and flexibility of on-demand hydrogen generation with our H-Cube and H-Genie systems through our application notes and scientific publication collection.

H-Genie hydrogen generators

The H-Genie hydrogen generators offer a versatile solution to perform safe and convenient hydrogenation in both batch and flow reactors (up to 100 bar pressure). These instruments serve as an efficient alternative to traditional hydrogen cylinders, offering enhanced flexibility for various applications.

Browse our application notes

Discover the potential of hydrogenation with our collection of hydrogenation-related application notes. We invite you to explore these valuable resources, providing insights, protocols, and real-world examples of successful hydrogenation processes.

The pharmaceutical industry is continually searching to automate techniques for rapid optimization or library production. The automation of hydrogenation is one of those processes that is drawing high interest due to its frequency in drug synthesis.

Catalytic asymmetric hydrogenation is one of the most efficient and convenient methods for synthesizing optically active compounds, which are widely used in the pharmaceutical and fine chemical industries.

Protecting groups play a central role in modern organic synthesis. Benzyl groups and Cbz groups are some of the most commonly used protecting groups and play a central role in the protection of alcohols, carboxylic acids and amines.

The H-Cube flow hydrogenation reactor is capable of performing reactions at 100 °C and 100 bar safely. The H-Cube’s improved mixing efficiency coupled with high temperature and pressure abilities means difficult reactions can be performed in minutes.

The hydrogenation of a series of functional groups has been performed using H-Cube. These experiments demonstrate that the H-Cube can perform a diverse range of heterogeneous hydrogenation reactions.

If you are looking for reaction examples with H-Cube Mini Plus, download our application overview. This short guide will help you to perform various types of hydrogenation reactions easily in a safe and efficient manner.

The H-Cube Pro offers greater hydrogen production capability. The reduction of 2,4-dinitroanisole was chosen as a model reaction as it has high hydrogen demand (6 mol H2 per 1 mol substrate) and involves reduction of two nitro groups.

In a medicinal chemistry project McCluskey and co-workers employed a series of chemoselective sequential hydrogenation reactions in order to access highly decorated norcantharidin analogues. This application note analyses their excellent work.

In this application note we demonstrate the first application on flow hydrogenation for the development of a PET radiotracer in a fast, efficient and reproducible way, with the H-Cube Pro flow reactor.

In this application note we demonstrate the results of newly developed Pd, Ni nanocomposites and immobilized Ir complex catalysts for a wide range of chemical applications in the H-Cube and H-Cube Pro systems.

In this application note we provide information from patents from major agrochemical companies, Syngenta and Dow Agrosciences, where flow chemistry was used for the synthesis of active compounds.

Read related publications

Discover research and scientific publications utilizing the H-Cube reactors and the H-Genie hydrogen generators for hydrogenation reactions.

Do you have questions?

Reach out to us at any time and experience fast and efficient support tailored to your specific needs.