H-Cube® Advance

The Future of Safe and Efficient Hydrogenations

Hydrogenation in continuous flow

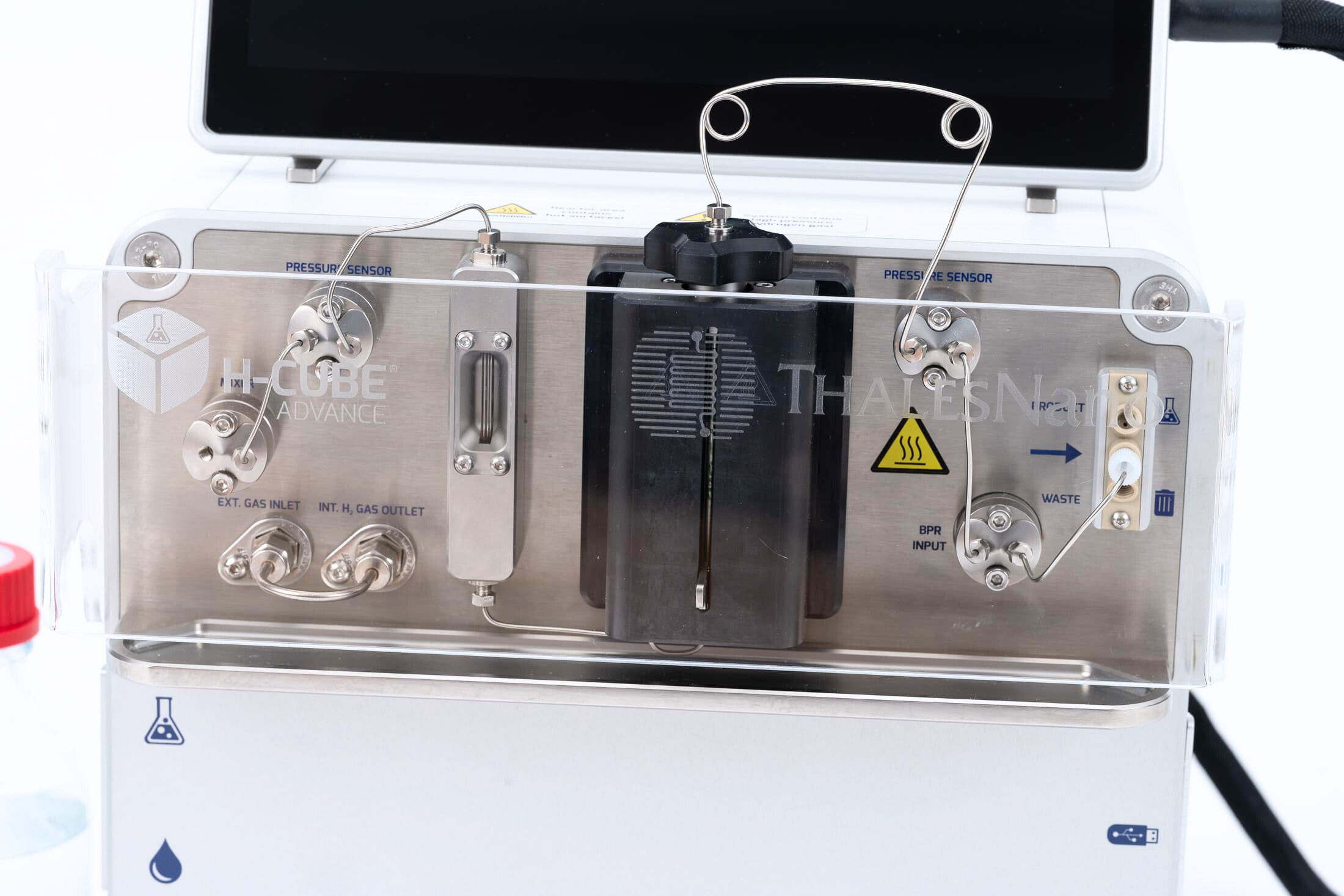

The new H-Cube® Advance is based on the well-known ThalesNano H-Cube® Pro. This compact, bench-top flow reactor, in addition to maintaining the basic functions of the original system, contains a number of improvements:

- Built-in MFC for the precise dosing of the produced hydrogen or the treatment of the external gases

- User-friendly interface, ergonomic design

- 3.0 (99.9%) produced hydrogen purity

- Compatibility with the THS ReAction software

Features of the H-Cube® Advance

New generation water electrolysis cell – single cell operation

External gas inlet - easy to reach on the front, allows the introduction of other gases besides hydrogen

External water reservoir – no problem with cleaning

Water purifier cartridge with ion-exchange resin to maintain water quality – enhanced cell longevity

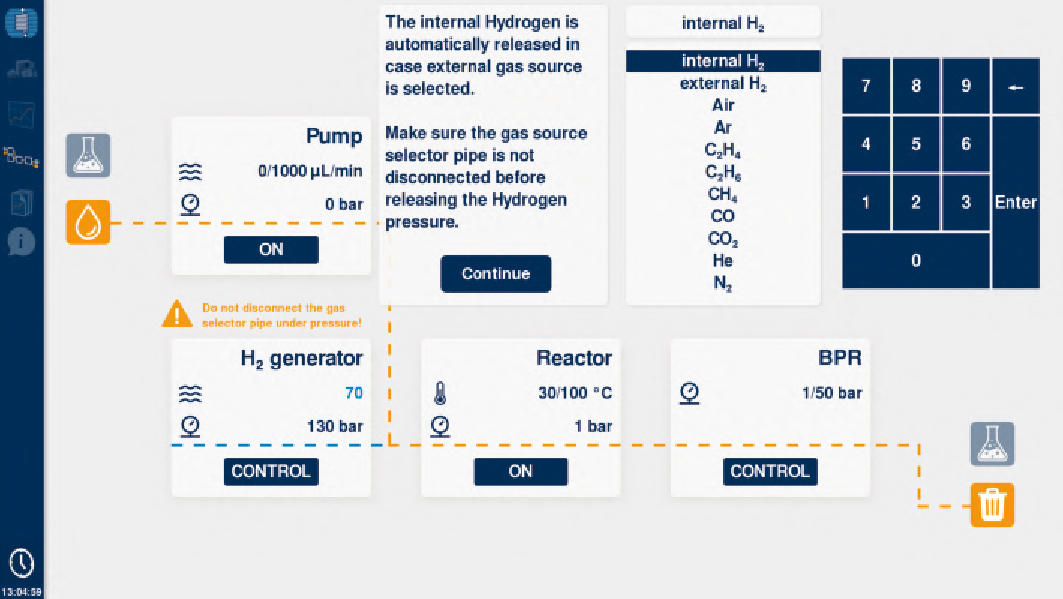

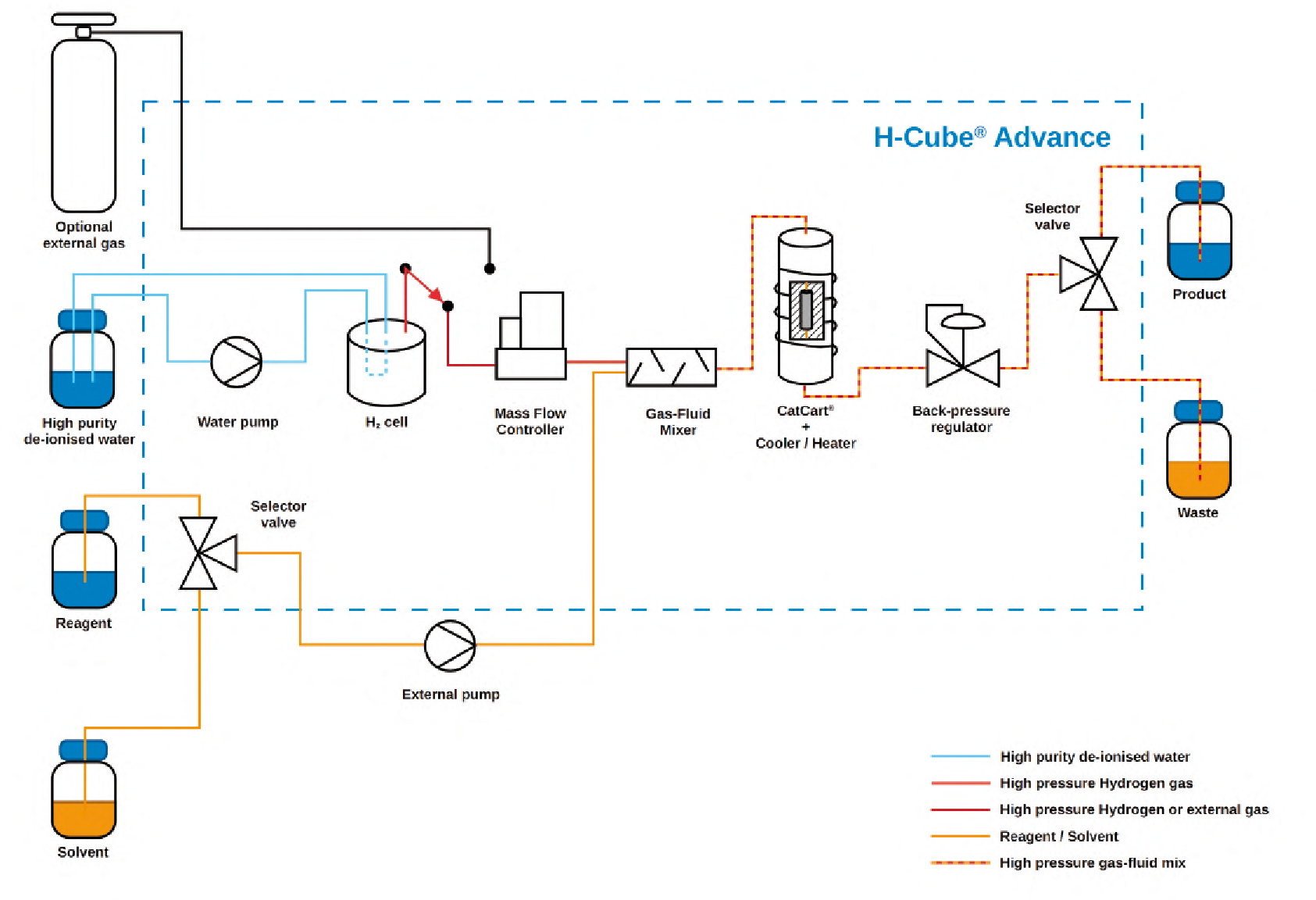

Gas flow (internal H2 or external) is controlled by mass flow controller

Compatible with CatCarts® of sizes 30 mm and 70 mm

Easy to use CatCart® holder with ergonomic fitting nut knob and lift lever

In-line see-through quartz tube with status indicator to visualize the gas-liquid flow

Improved system valve and mixer

Compatible with the THS HPLC and Knauer pumps

External 11.6” screen touch display user interface

Remote control option via RS-232 and ThalesNano CAN bus

ThalesNano ReAction software compatibility: The H-Cube® Advance can be a member of a large automated modular reactor system, with all parts connected to each other, and controlled by the THS ReAction software

User friendly software with automated and manual mode

Automated Mode

Manual Mode

How does it work?

The H-Cube® Advance is mainly used for hydrogenation of many different starting material types, as well as catalyst screening. Additional supplied equipment, such as the HPLC pump, is used to introduce the reactant into the device, where the solution of reactant is mixed with the in-situ on-demand generated hydrogen.

The pre-heated mixture is then transferred to a disposable catalyst cartridge (CatCart®) which is preloaded with the required solid catalyst.

The mixture is then passed through the solid phase and then collected in a flask. In most reactions the only work-up required is the evaporation of the solvent.

Applications

Reactions with hydrogen gas:

Triple bond full reduction, debenzylation, nitrile reduction, selective nitro reduction, selective triple to double bond reduction, selective double bond reduction, aldose reduction, aromatic heterocycle reduction, aromatic ring reduction

Other reactions:

Deuteration, Sonogashira coupling, Suzuki coupling

Compatible systems

The H-Cube® Advance is compatible with other reactor modules to give users chemistry capabilities beyond hydrogenation:

Gas Module

When the Gas Module is connected to the H-Cube® Advance, it allows the introduction of other gases than hydrogen, such as carbon monoxide, oxygen or Syngas. The user can choose from 14 different gases to be applied at up to 100 bar pressure, widening the reactor’s chemistry ability significantly.

Recommended gas regulators:

N2 regulator: Linde C200/1A-200B

O2 regulator: Rhöna EN OX 03-10

H2 regulator: Linde fdr-200-100-380-h

Phoenix™ Flow Reactor

The Phoenix™ Flow Reactor is a powerful instrument which can be heat the reaction zone up to 450 °C and is compatible with multiple types and sizes of reactors (CatCarts®, MidiCarts™, coiled reactors, metal-metal sealed catalyst columns). When connected to the H-Cube® Advance , it is possible to set up a system to perform single or double-step reactions in series and to monitor and control the whole process using the interface of the H-Cube® Advance.

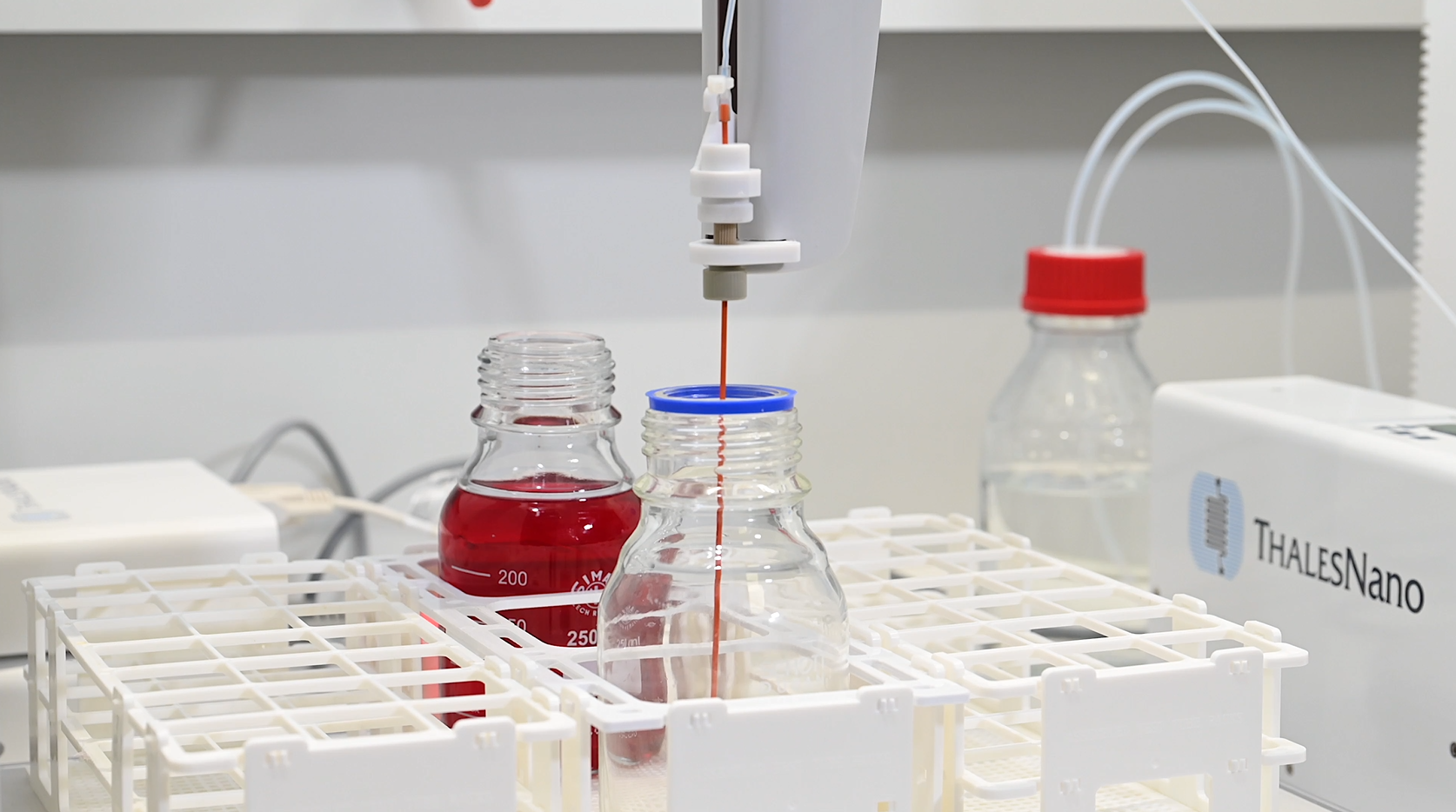

Autosampler system

Fully automated processes can be implemented when connecting the H-Cube® Advance with one of the Brooks AIM3000 Autosampler systems which are ideal for performing optimization studies or catalyst screening.

System specifications of the H-Cube® Advance

| Technical Specifications | |

|---|---|

| Solvent and reagent flow rate range | 0.001-10 mL/min |

| Internal H2 gas flow rate range | 1-70 NmL/min |

| Gas types | Internal H2 or external custom |

| Pressure range | Atmospheric to 100 bar |

| Reactor temperature range | 0 – 150 °C (32 – 302 °F) |

| Dimensions (H x W x D) | D330 x 320 x 330 mm (w/o display) |

| Display size | 11.6” (29.464 cm) |

| Weight | 18 kg |

| Mains range | 110 – 240 V AC, 50/60 Hz, 500 W |

Preorder now!

The H-Cube Advance will be commercially available in Q1, 2025. Now, for a limited period, you can submit your interest in it, and secure an order with a more beneficial, introductory price. Fill out the form below and we’ll contact you with details.

Do you have questions?

Reach out to us at any time and experience fast and efficient support tailored to your specific needs.